Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Polymer Name

- Reinforcement Material

- Composite Materials Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Features

• Wide range of Fiber Areal Weight, including extremely light tapes

• Toughened epoxy resin system

• High prepreg flexibility

• Low tack

• Out life of 80 days at 21°C (70°F)

- Benefits

• Almost unlimited possibilities of composite structure design

• High mechanical properties

• Easy handling and dressing in a mold

• Possibility of repositioning material in the mold

• Possibility of making large and/or complex parts with long mold dressing time before curing

Applications & Uses

- Markets

- Applications

- Composites End Use

- Composites Processing Methods

Properties

- Typical Properties

Value Units Test Method / Conditions Density 1.24 x10^3 kg/m3 ISO 1183 Flexural Modulus 3.3 GPa ISO 178 Flexural Strain to Failure 4.1 % ISO 178 Flexural Strength 120 MPa ISO 178 Tensile Modulus 3.1 GPa ISO 527 Tensile Strain to Failure 1.92 % ISO 527 Tensile Strength 54 MPa ISO 527 Tg by DMA 127 °C DMA Onset E’ Tg by DSC 142 °C -

Regulatory & Compliance

- Notice

The information contained in this publication is based on actual laboratory data and field test experience. We believe this information to be reliable, but do not guarantee its applicability to the user’s process or assume any responsibility or liability arising out of its use or performance. The user has to determine the properties of its own commercial compounds when using this product. Because of numerous factors affecting results, we make no warranty of any kind, express or implied, including those of merchantability and fitness for a particular purpose.

Technical Details & Test Data

- Instructions for use

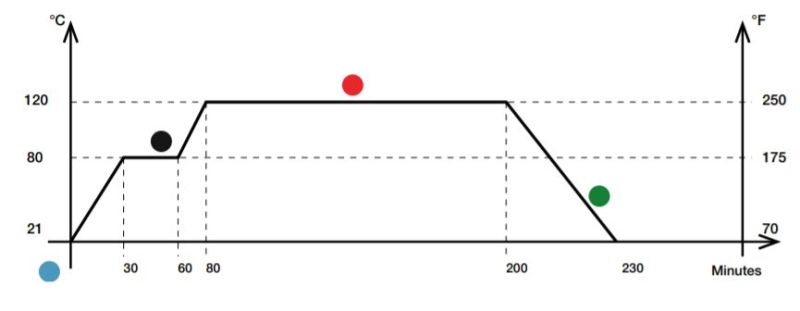

Curing cycle

THINPREG™ 513 offers its best performance when molded in an autoclave at 120°C / 250°F with a maximum pressure of 6 bars. THINPREG™ 513 can also be cured out of autoclave, in a vacuum bag.Recommended curing conditions in autoclave for a monolithic part (<15mm thick)

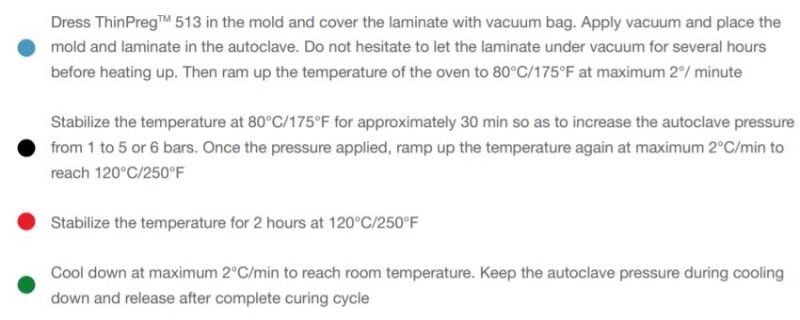

- Resin viscosity profile

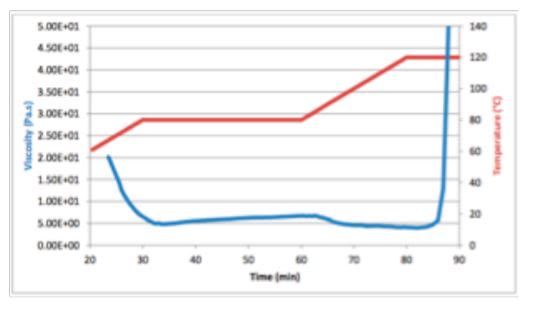

- Cured THINPREG™ TP 513 laminate properties

Cured ThinPregTM 513 laminate properties (after the above mentioned curing cycle has been applied) With Toray Fiber T700 With Toray

Fiber M40JTest Method Fiber volume / weight fraction 57 / 66 % 57 / 66 % Inter Laminar Shear Strength for the laminate structure: 100%@0° 83.0 MPa 76.5 MPa ASTM 2344 Tensile Modulus (corrected to 60% Vol Frac) 136.3 GPa 221.2 GPa ASTM D3039 Tensile Strength 2609 MPa 2104 Mpa ASTM D5467 Compressive Strength 176 ksi ASTM D5467

Safety & Health

- Health and safety

THINPREG™ 513 contains epoxy resins which can cause allergic reaction. When uncured, ThinPregTM 513 should be handled with appropriate gloves. When cured, a composite laminate made of THINPREG™ 513 should be cut, drilled or machined in a room equipped with an exhaust ventilation and filtration system, by operators wearing protective cloth and masks.

Packaging & Availability

- Packaging

THINPREG™ 513 is wound into 300 mm (11.8 inches) wide rolls on a 76 mm (3 inches) inner diameter cardboard tube. THINPREG™ 513 is supported on a bottom silicon paper. The standard roll length is 150 linear meters (164 yards).

Storage & Handling

- Storage

THINPREG™ 513 should be stored at -18°C (0°F) to reach the maximum shelf life of 24 months. At 21°C (70°F), the out life is 80 days.