Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Polymer Name

- Reinforcement Material

- Composite Materials Functions

- Technologies

- Product Families

Features & Benefits

Applications & Uses

- Markets

- Applications

- Composites End Use

- Instruction for Use

Various core materials can be used with the GF736 adhesive film system, including certain foams - provided that special procedures are followed - and also honeycombs.

Nomex or aluminum honeycomb cores

1. Core to First Skin For bonding honeycomb into place on to a cured laminate, a minimum of a 250g film should be used, with extra resin film used where there are any steps, wrinkles or unevenness in the laminate or core material surface profile. Apply the film over the laminate with the paper side uppermost, then remove the release paper. Bed in the honeycomb core to the film and splice the core segments with a wrap of at least two layers of film applied to each honeycomb edge. After positioning all the core pieces, vacuum the core in place using at least -0.8 bars vacuum and cure the adhesive film for a minimum of 4 hours at 85ºC (185ºF). The full cure required will be achieved when the outer skin is cured and bonded into place, using one of the cure cycles below.

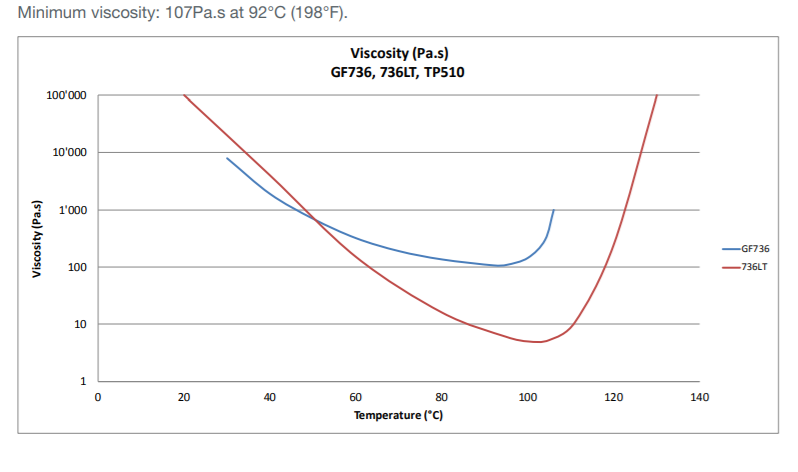

2. Second Skin to Core One procedure is to co-cure the outer skin together with the core bond. For this, a single layer of 250g adhesive film should be rolled over the honeycomb surface, and bedded well into the cells. In this way it should be possible to reposition any misplaced prepreg plies, without disturbing the adhesive layer. With a controlled flow system such as 736LT, care should be taken to ensure that excess resin is not removed from the adhesive interface, by using a fine microporous release film. It is also critical when using this process that adequate precautions are taken to perforate the skin to allow air removal from the Nomex prior to gelation (e.g through the use of a spikey roller). Failure to do so may result in skin blow off (contact North Thin Ply Technology Technical Services for details).

Foam Core Materials

Due to the wide variety of foams available and the cure temperatures involved, special procedures have been developed which must be carefully followed when using foam core materials with GF736. For details of these processes, please contact NTPT’s Technical Service or sales team. Use of GF736 with untreated foams is not recommended due to potential inhibition of cure in the adhesive film.

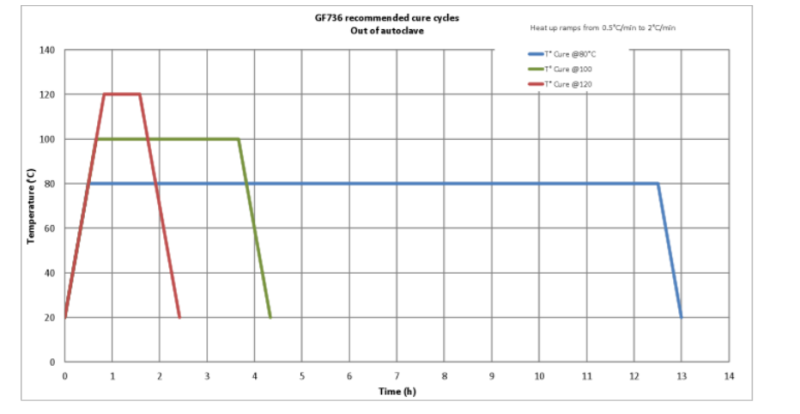

Cure cycles

For full cure of GF736 to be achieved, one of the following cure cycles is recommended. If GF736 is being cocured with a prepreg skin, then the cure cycle used for GF736 will also be that of the prepreg in the laminate. Where required cure cycle of the prepreg being used and the GF736 is different, then whichever cure is the longest should be applied.

Technical Details & Test Data

- Typical Characteristics

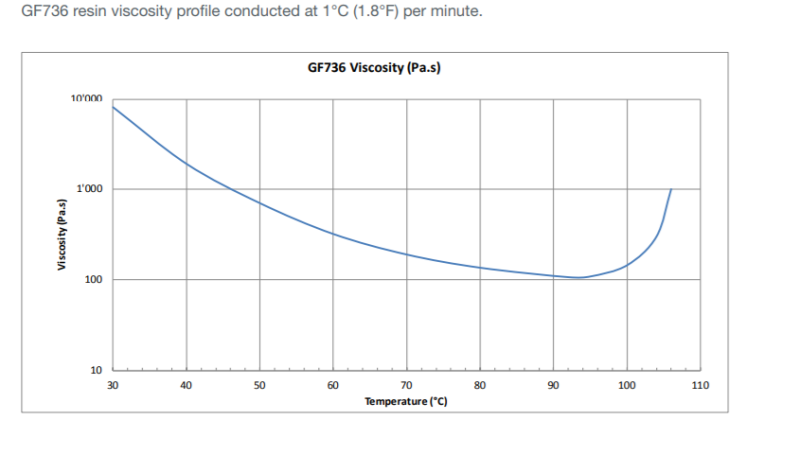

Rheology

- Typical Characteristics

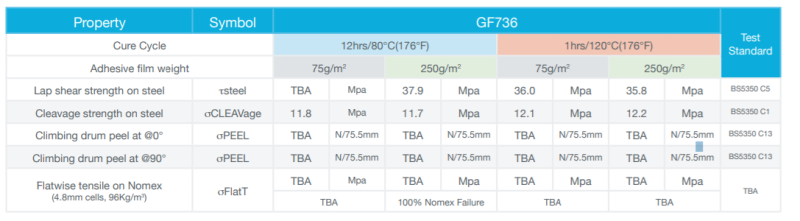

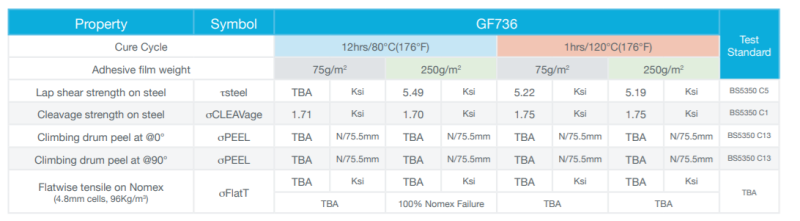

Cured adhesive mechanical properties (SI)

Cured adhesive mechanical properties (Imperial)

Storage & Handling

- Storage

When stored sealed & out of direct sunlight.

Storage Temperature Value Unit -18°C 0°F 24 Months +18-22°C +64-72°F 6 Weeks All prepreg materials should be stored in a freezer when not in use to maximize their useable life, since the low temperature reduces the reaction of resin and catalyst to virtually zero. However, even at -18°C (0°F), the temperature of most freezers, some reaction will still occur. In most cases after some years, the material will become unworkable