Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Fillers Included

- Polymer Name

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

- key Characteristics

- Injection molding grade

- Biopolymer compound, mineral filled

- Can be blended with bamboo powder (B), rice husk (R), coffee husk (C), wheat straw (W) and wood powder (H)

- Balanced flexibility to rigidity, good impact properties

- Naturally heat-stable up to 95°C

- Biodegradable in controlled (e.g. industrial compost) und non-controlled conditions (e.g. landfill, soil, roadside)

- Easy to process / easy to eject

- Food contact safe

- Dishwasher-ok, microwave-ok

- Global availability.

Bioblend BT25S (B/R/C/W/H) HH is a bio-polymer polymerized of succinic acid and 1,4-butanediol. The compound is enhanced with a blend of natural mineral and organic fillers. The material can additionally be blended with bamboo powder, rice husk or coffee husk to support a natural look.

Bioblend BT25S (B/R/C/W/H) HH is designed to be completely biodegradable & compostable (microbial and enzymatic degradation) in the targeted disposal environment; it is biodegradable both in controlled (e.g. industrial compost factilities) and in non-controlled (e.g. soil, roadside, landfill) conditions.

The grade offers a significant reduction in carbon footprint compared to traditional fossil-based plastics. The material has got balanced stiffness values with good impact properties. Bioblend BT25S (B/R/C) HH offers a very good processability and flow with an easy ejection of parts from the mold. Cycle times can be kept short.

Part wall-thickness shall be greater than 1.2 mm.

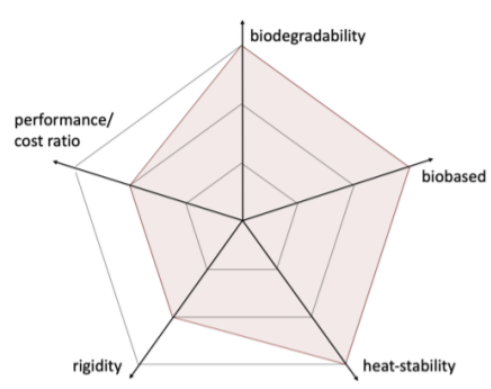

- key Characteristics

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Applications

Typical applications where Bioblend BT25S HH is used for are

- Consumer goods

- Kitchen ware (single use/season use cutlery, cups, boxes, trays, baby spoons)

- Toys

- Packaging, rigid packaging

- Personal care (tooth brush handle, soap box)

- Beauty (crème containers)

- Outdoor

- Process Guidelines

Bioblend BT25S (B/R/C/W/H) HH can be processed on conventional injection molding equipment. The material is sensitive to moisture and high temperatures (above 190°C); high shear rates shall be avoided. The matrial needs to be dried before processing.

- Drying

Dry the material for a minimum of 4 - 6 hours at 80o C. A moisture content of less than 0.07% (700 ppm) is required / less than 0.10% (1000 ppm) is recommended. Avoid exposing the material to atmospheric conditions after drying; process immediately.

- Injection Moulding Start-Up

- Vacuum-out/clean hopper and air-suction system to avoid contamination.

- Clean/purge the barrel.

- Once the barrel has been cleaned, reduce barrel temperatures to the right set points (see next section).

- Introduce the compounds into the barrel only after all barrel temperatures are at target set points. The material cannot enter into the barrel when temperatures are above 190°C in any section!

- Make sure that the mold is heated up to a temperature of around 50°C.

- Start with a moderate holding pressure and keep it applied for long initially.

- Start with long cooling times before opening the mold: tcooling (in sec) > biggest wall-thickness (in mm) x 10.

- After start-up, the injection molding process shall be optimized step-by-step to industry relevant process paramaters.

Properties

- Physical Form

- Typical Properties

Value Units Test Method / Conditions Density 1.3´ g/cm3 - Melt Flow Rate (190°C/2.16 kg) 15 g/10 min ASTM D1238 HDT-B (0.46 MPa) 95 °C ASTM D648 Melting Point 115 °C ISO 3146 Tensile Strength (50 mm/min) 22.7 Mpa ASTM D638 Flexural Strength 36.1 Mpa ASTM D790A Flexural Modulus (1% secant) 1.2 Gpa ASTM D790A Elongation at Yield (50 mm/min) 18.7 % ASTM D638 Elongation at Break (50 mm/min) 18.8 % ASTM D638 IZOD Notched Impact Strength (at 23°C) 44.54 J/m ASTM D256 Mold Shrinkage 0.45 % - - Processing Information (Injection Molding)

Value Units Test Method / Conditions Hopper Temperature 50 °C - Feed Zone Temperature 170 °C - Compression Zone Temperature 180 °C - Metering Zone Temperature 190 °C - Nozzle Temperature 185 °C - Mould Temperature 30-40 °C - Screw Speed Low – Medium - - Injection Pressure Medium - - Holding Pressure Low – Medium / Long - - Injection Speed Slow – Medium - - Cooling Time Medium - Long - -

Storage & Handling

- Storage

Keep the material tightly closed in a dry and cool place. Keep away from heat and sources of ignition and avoid exposure to moisture, dampness. Do not stor outdoors. Use material within 6 month after delivery.