Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Food Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- Food Ingredients Features

- Functional Benefits

- Provides uniform suspension of insolubles like matcha powder, calcium minerals

- Improves emulsification, reduces tendency of fat and serum separation

- Improve heat stability of plant proteins, and minimizes instability during heat processing

- Enhance mouthfeel, providing a smooth and full-bodied mouthfeel

- Product Features

- Unique combination of selected emulsifiers and stabilizers.

- Easy to use functional system powder.

- Versatile functional system for use in dairy alternatives beverages.

- Selection of MASBLEN based on viscosity and mouthfeel desired.

Applications & Uses

- Markets

- Applications

- Food & Nutrition Applications

- Use Level

- 0.27 - 0.33%

- Application Areas

UHT Dairy Alternative Milk

- Recommended Dosages

For a standard 1.50% protein and 0.80% fat oat soymilk, the recommended dosage is 0.27 - 0.33%.

Actual dosage levels will vary depending on the formulation.

Properties

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Outcome & Results

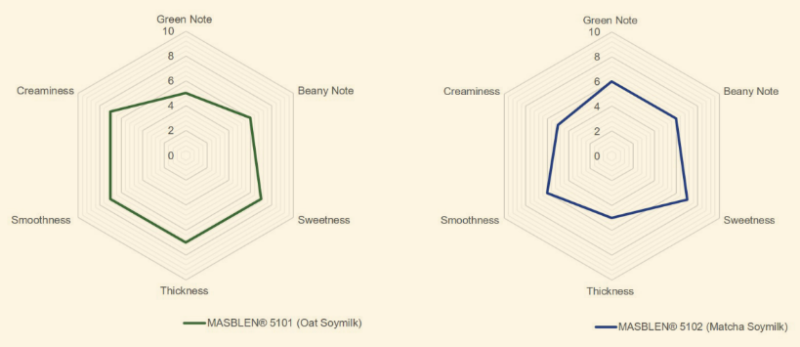

MASBLEN® 5101, 5102, effectively aids in suspension of insoluble particles and provides homogeneity; stabilizes plant proteins and reduce tendency of flocculation; gives viscosity, provides creaminess and improve overall texture/mouthfeel.

MASBLEN® 5101, 5102 impacts perception of smoothness, creaminess, green notes and sweetness of Oat Soymilk and Matcha Soymilk.

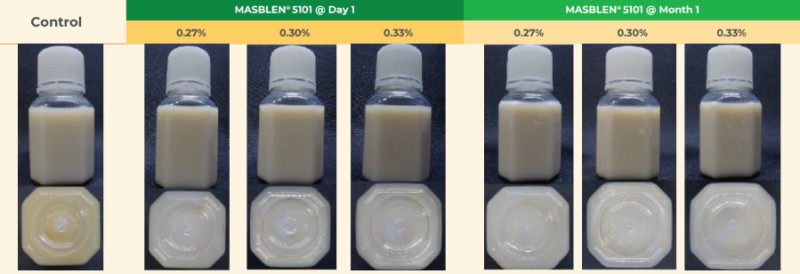

MASBLEN® 5101 provides suspension and stabilization of insoluble particulates in dairy alternative beverages, such as oat soymilk.

MASBLEN® 5101 in Application Performance - Physical Stability

Storage at ambient ~28°C

- Recipe Suggestion

Fresh Soymillk 40.00% Oat Powder 1.30% Sugar 5.00% MASBLEN® 5101 0.27 - 0.33% Flavoring As required Coloring As required Water to 100% - Procedure

- Add soymilk into water, and preheat to 45-50oC.

- Dry blend MASBLEN® 5101 with sugar and oat powder, then disperse into soymilk with agitation and mix for 10 minutes.

- Check pH of soymilk solution and adjust pH to 6.70 if required.

- Pasteurize the soymilk solution to 70°C.

- Homogenize milk at 50/200bar at 70°C

- UHT process at 140oC for 5-10 seconds, then cooling at 1st cooling 35oC and 2nd cooling 20-25oC

- Fill into aseptic bottles and store.