Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Polymer Name

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Product Benefits

- Enhanced PAI formula

- Low ionic content & low out- gassing

- Excellent heat resistance

- Minimized rate of erosion in plasma chambers

- Optimal chip resistance, durability, and machinability

- Designed specifically for demanding chamber applications

- Clean, Resistant and Optimized Material Solution for Vacuum Chambers

The product shows increased lifetime over traditional materials such as polyimide, for example up to 25x over polyimide in ozone in some cases, and is often specified against traditional materials used in vacuum chamber applications such as quartz, ceramics, polyimides and other engineering plastics, as MPR1000 lasts much longer over time.

- Product Details

The material was developed based on three key premises:

- Longevity - Increased life in plasma chambers over traditional plastics such as polyimide (up to 25X over polyimide in ozone)

- Clean - Low ionic metal content and low out-gassing

- Value - Lower overall cost in use compared to traditional materials used in vacuum chamber applications such as quartz, ceramics, and engineering plastics

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers End Uses

- Product Applications

- Vacuum chambers that utilize oxygen plasma

- Clamp rings, trench rings, hangers, screw pins, and shower heads

- Centering pins, focus rings, insulators, vacuum pads, and wafer guides

Properties

- Color (Properties)

- Flame Rating

- Physical Form

- Mechanical Properties

Value Units Test Method / Conditions Tensile Strength 99 MPa ISO 527-1/-2 Tensile Strain (Elongation) at Break 3.5 % ISO 527-1/-2 Tensile Modulus of Elasticity 6050 MPa ISO 527-1/-2 Shear Strength 83 MPa ASTM D732 Compressive Stress (1 / 2 / 5 % Nominal Strain) 47/ 79/ 130 MPa ISO 604 Charpy Impact Strength (Unnotched) 62 kJ/m² ISO 179-1/1eU Charpy Impact Strength (Notched) 5 kJ/m² ISO 179-1/1eA Hardness 102 Rockwell M ISO 2039-2 - Thermal Properties

Value Units Test Method / Conditions Glass Transition Temperature (DMA, Tan Delta) 277 °C DMA Thermal Conductivity (23°C) 0.5 W/(K.m) - Coefficient of Linear Thermal Expansion (23 - 60°C) 29 µm/(m.K) - Coefficient of Linear Thermal Expansion (23 - 100°C) 30 µm/(m.K) - Coefficient of Linear Thermal Expansion (min. 150°C) 36 µm/(m.K) - Heat Deflection Temperature (Method A: 1.8 MPa (264 PSI)) 278 °C ISO 75-1/-2 Continuous Allowable Service Temperature in Air (20.000 hrs) 260 °C - Flammability: (3 mm (1/8 in.)) V-0 - UL 94 - Miscellaneous Properties

Value Units Test Method / Conditions Density 1.47 g/cm³ ISO 1183-1 Water Absorption (After 24h Immersion in Water of 23°C) 0.28 % ISO 62 Water Absorption (At Saturation in Water of 23 °C) 3.4 % -

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

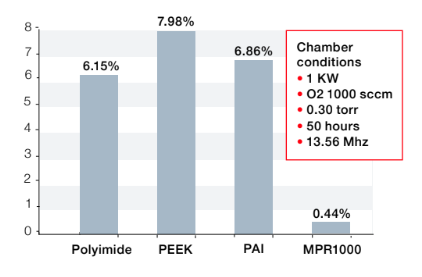

- Percent Weight Loss in Oxygen Plasma - Lower Energy

Semitron® MPR1000 has less than 0.5% erosion in 1KW O2, 13x better than PI