Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Product Features

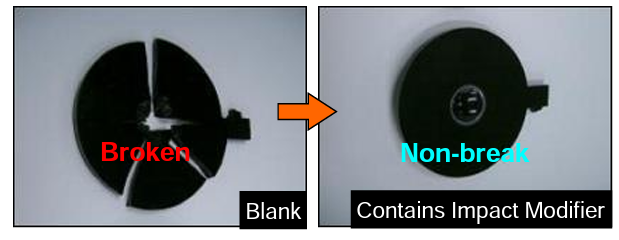

High impact strength

- Product Benefits

PVC

- Processability

- Mechanical Properties

- Dispersibility of Fillers

- Productivity

Engineering Plastics

- Mechanical Properties

- Flame retardancy

- Processability

Polyolefins Elastomers

- Processability

- Flame retardancy

- Dispersibility of Fillers

- Productivity improvement

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Recommended Applications

- Applicable Polymers & Resins : PC, PC polymer alloy, PVC etc.

- Applications

- Automotive & Transportation

- Electric & Electronic

- Aerospace & Aviation

- Consumer goods

Properties

Technical Details & Test Data

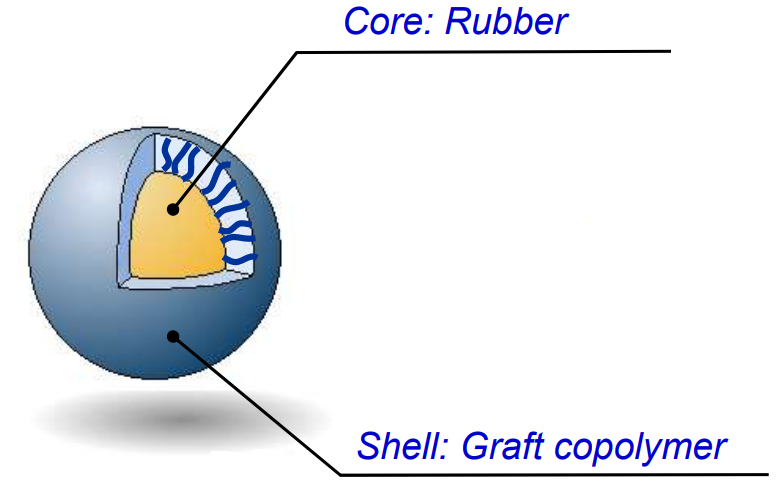

- METABLEN ’s Impact Modifier Technology

METABLEN’s Impact Modifier Technology

- METABLEN has various materials such as acrylic, silicone/acrylic, and butadiene.

- Shell (graft) gives rubber particles suitability to matrix resin.

Particle size : 0.1~1μm

Rubber type Rubber elasticity

(at R.T.)Rubber elasticity

(at low temp.)Weatherability Acrylic ++ + ++ Silicone/Acrylic ++ ++ ++ Butadiene ++ ++ - W-450A is acrylic rubber type impact modifier.

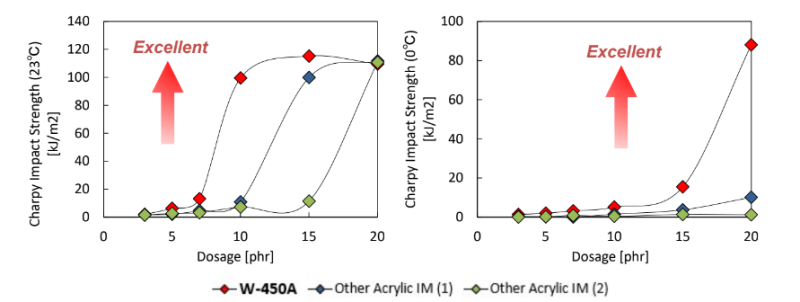

- METABLEN W-450A: Impact Modifier for PVC

Fig. Charpy impact strength of PVC.

W-450A shows better impact strength than other acrylic impact modifiers.

Formulation (set value) PVC (Pn=800) 100 (phr) Octyl tin stabilizer 1.5 Inner lubricant 0.5 Outer lubricant 0.5 Metablen P-551A 1 Color 0.03 Impact modifier Val. Test condition (set value) :

- Roll : 190°C * 3 min 0.5 mm

- Press : 185°C * 5 min

- Strength : 4 mm * 8 mm (2 mm notched)

- Improved Plastic Toughness