Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Chemical Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

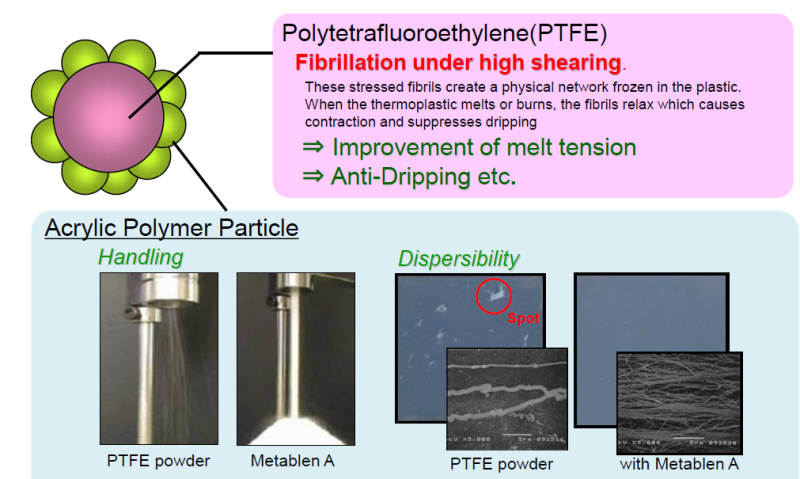

- METABLEN A: Features of Modified PTFE

METABLEN A-type has better handling property than pure PTFE. METABLEN A type has high dispersibility to matrix resin, and forms fibrillar network structure.

METABLEN A-type can be used as processing aid and anti-dripping agent. It consists of PTFE, modified by acrylic polymer hybrid technology.

- Product Benefits

PVC

- Processability

- Mechanical Properties

- Dispersibility of Fillers

- Productivity

Engineering Plastics

- Mechanical Properties

- Flame retardancy

- Processability

Polyolefins Elastomers

- Processability

- Flame retardancy

- Dispersibility of Fillers

- Productivity improvement

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- METABLEN A-3000 : Suitable Usage

WPC

(wood plastic compound)Sealer Functional Seats Foams Electronic Use Images of Products

Processability profile extrusion +++ +++ ++ +++ sheeting +++ stretching +++ foaming +++ mess reduction + + + Appearance ++ + + Filler dispersity +++ +++ Flame resistence (anti-dripping) +++ +++ - Wood deck

- Furniture

- Automotive

- Elastomers

- Housing

- Graphic Sheet

- Conductive Sheet

- Heat Insulator

- Weight Saving

- Automotives

- Electric wire

- Optical cable

- OA machine

Properties

Technical Details & Test Data

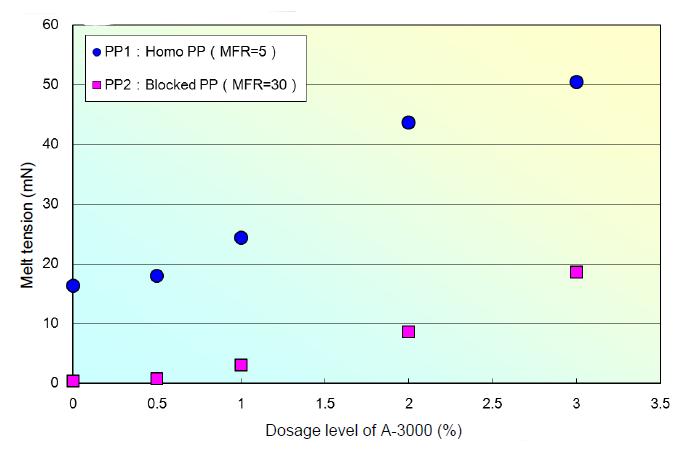

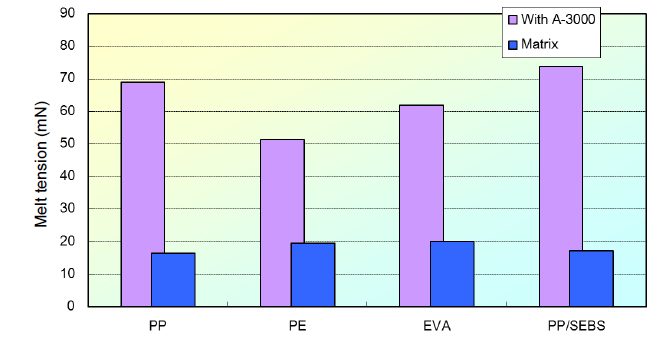

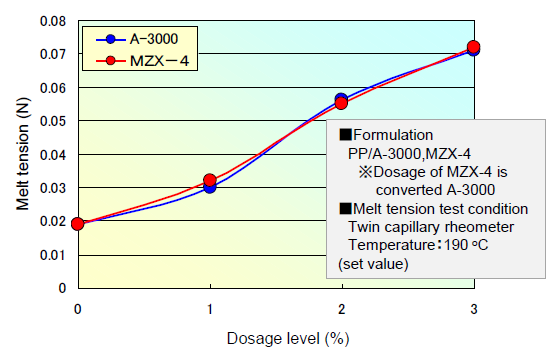

- METABLEN A-3000:Improvement of Melt Tension

Evaluation Method (set value) PP/A-3000 composition was extruded at a constant extrusion rate using a capillary rheometer (Rosand RH-7(trademark) by Malvern), the strand was pulled at a constant rate (10m/min), and the melt tension was measured. The L/D of the die was 16mm/1mm, and the measuring temperature was 190 °C.

Composition (set value) Blending Ratio: Matrix/A-3000=95/5 . Matrix

- PP:Homo-PP(MFR=5)

- PE:HDPE(MFR=0.8)

- EVA: PE/VAC=83/17

- PP/SEBS=80/20

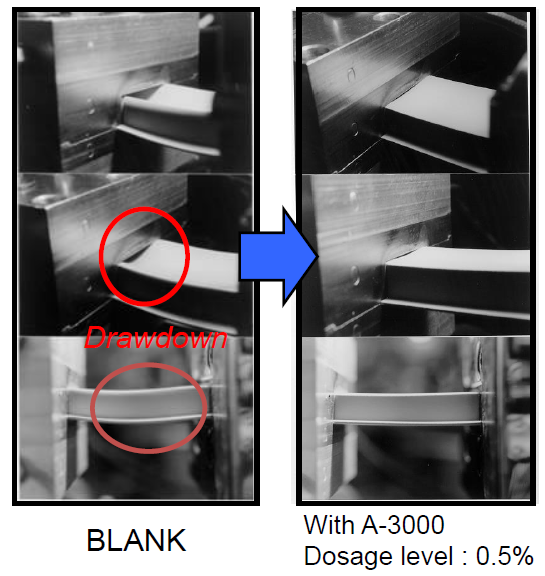

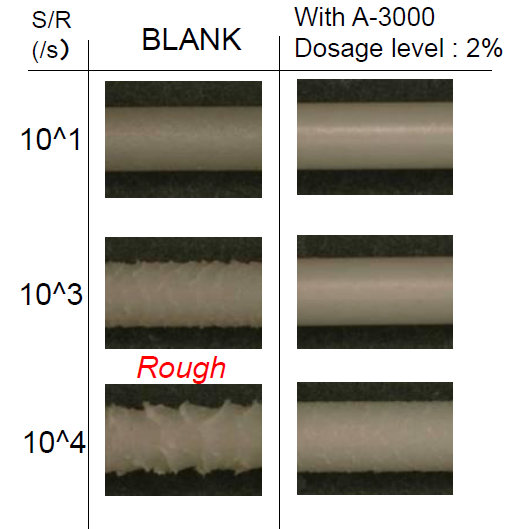

- METABLEN A-3000 : Example of Processability Improvement

Profile Extrusion

PP: Homo polymer with 30% talc (MFR=1g/10min)

Extruding Molding

- METABLEN A-3000: Master Batch

METABLEN A-3000 also offers the master batch which used PP and PE as base resin.

The master batch which is easy to distribute is excellent in appearance compared with powder.Master Batch Base resin A-3000 Content MZX-4 Homo PP

(MFR = 5g/10min)20% MXE-4 PE

(MFR = 5g/10min)20%

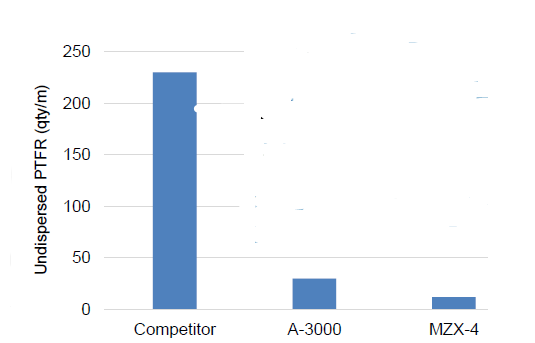

~Appearance~(MCC Method)

(set value)

- Formulation PP -(MFR5g/10min):99.5~99.8phr Processing add:PTFE content 0.1phr

- Compound & Molding - Compound : 30mm twin extruder Molding: 30mm Single extruder Die : T-Die(Film thickness:500μm Width:8cm)

- Evaluation - The poor appearance (Spot) of the PTFE origin in 1m films is counted using a microscope.