Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

Applications & Uses

- Markets

- Applications

- Compatible Substrates & Surfaces

- Coating End Applications

Properties

- Physical Form

- Appearance

- Solid bead

- Soluble in

- Toluene, Methyl Ethyl Ketone (30% in Solvent), Acetone (30% in Solvent), Ethyl Acetate (30% in Solvent), Dimethyl Carbonate (30% in Solvent), t-Butyl Acetate (30% in Solvent), n-Butyl Acetate (30% in Solvent), Parachlorobenzotrifluoride (30% in Solvent)

- Insoluble in

- Isopropyl Alcohol (30% in Solvent), Methanol (30% in Solvent), Mineral Spirits (30% in Solvent), Water (30% in Solvent)

- Typical Properties

Value Units Test Method / Conditions Glass Transition Temperature (Onset, Calculated) 48.0 °C - Molecular Weight 60000.0 - - Acid Number 3.4 mg KOH/g Resin - - Note

Typical physical properties listed are approximate values and should not be considered manufacturer’s release specifications. Manufacturer’s release specifications are subject to change without notice, please contact your representative for the latest product specification details.

- UV Applications

Monomer

20% in Monomer

Dissolved with 10 min. heat at 65°C*HDDA 400 cps NPGDA 770 cps *Viscosity was measured at 25°C

Technical Details & Test Data

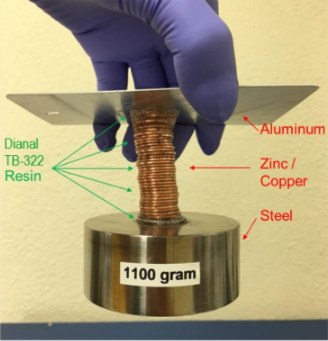

- Metal Adhesion Performance in Coatings

Adhesion Performance1 Flexibility2 Cold-Rolled Steel 5 (excellent) Pass Galvanized Steel 5 Pass Aluminum 2024 5 Pass Aluminum 5052 5 Pass Zinc 5 Pass Tin 5 Pass Copper 5 Pass Brass 5 Pass Note:

- Coatings was formulated at 40% solids in toluene without external plasticizer. The adhesion test was carried out after the film was dried at room temperature for one week.

- 1Adhesion is rated on a 0 (poor, >65% coating area removed) to 5 (excellent, no failure) scale as described in ASTM D3359.

- 2Flexibility is determined by the degree of cracking at a bend. The bend was performed after drying the coatings for one and four weeks at ambient temperature.

- Technical Data

Adhesion on Metals (crosscut test per ASTM D3359)

Strong adhesion on multiple substrates

- Preparing Solutions

Our resins dissolve at room temperature but require constant agitation to prevent solvent-swollen granules of polymer from forming agglomerates and sticking to the walls of the vessel. Important: The polymer beads should be sifted directly into the vortex of the stirred solvent to speed wetting-out and dispersion. Continuous low-shear agitation for periods of 1-12 hours, depending on the grade and concentration of resin, is recommended.

After the solution appears clear in the tank, a sample should be spread out on a Leneta card or glass. After the solvent evaporates and a film forms on the card or glass, there should not be any resin seeds. If there are any seeds, the tank should be agitated further to fully dissolve the resin. Tank agitation should not be stopped (except for sampling) until the film test indicates there are no resin seeds. Any cloudiness or residue may indicate that some polymer remains undissolved. The presence of water in the system can also cause cloudiness.

Solution time can be reduced by heating; most common solvents can be heated to approximately 49°C (120°F) without the need for reflux equipment. High-shear agitation also cuts dissolving time, but requires care to avoid overheating and excessive solvent loss.