Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Performance Benefits

- Excellent damage tolerance

- Large and light weight

- Chemical resistance

- Dimensional stability

- Electrical insulating properties

- Outstanding surface finish

- Design and Processing Benefits

- Low pressure pr°Cessing

- Design freedom

- Large & complex part capability

- No mold releasing agent

- Short cycle time

- Low capital investment

- No fiberglass

- Multiple Molds per Machine

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers Processing Methods

Properties

- Mechanical Properties

Value Units Test Method / Conditions Density₁ 0.97 g/cm3 ASTM D792 Tensile Strengthat yield₁ 36.6 MPa ASTM D638 Tensile Modulus₁ 1.73 GPa ASTM D638 Tensile Elongation at Yield₁ 5.8 % ASTM D638 Flexural Strength at 5% strain₁ 58.0 MPa ASTM D790 Flexural Modulus₁ 1.7 GPa ASTM D790 Notched Izod Impact at 23ºC₁ 320.0 J/m ASTM D256 Deflection Temperature Under Load (at 264 psi)₁ 109.0 ºC ASTM D648 - Note

Plaques molded at cavity and core temperatures of 87°C and 57°C respectively. Mechanical properties are based on conservative values either long-term aged or freshly molded.

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

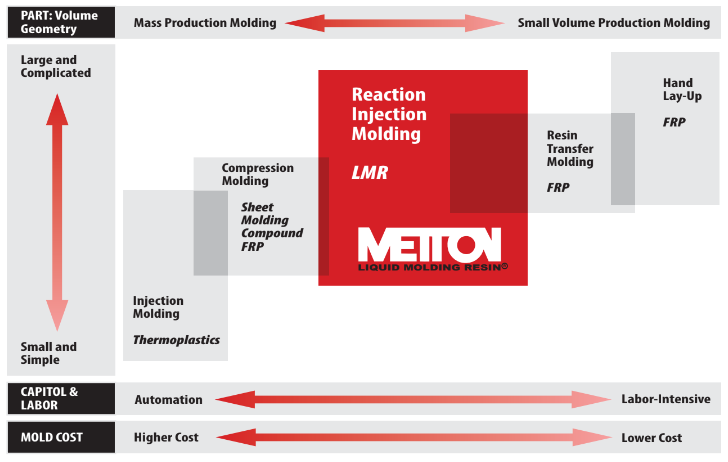

- Process/Material Comparisons

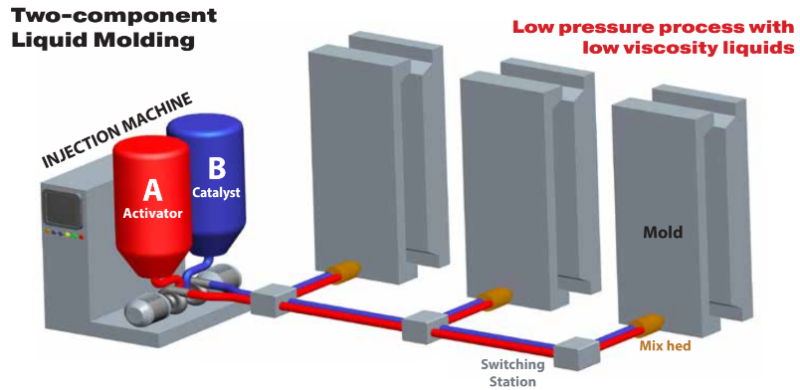

- Reaction Injection Molding

- Inject multiple molds with 1 injection machine (typically 5)

- Viscosity similar to motor oil @ 300 centipoise

- Inject parts up to 13 m2 (140ft2) or > 100 kg (220 lbs)

- Cavity pressure of 15 to 30 psi (design mold to maximum 50 psi)

Packaging & Availability

- Packaging Type