Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

- Typical Properties of the Coating

- long term antifog, antiblock and antistatic finishing for several years

- surface resistance as far as 109 Ω at standard climatic conditions

- strong adhesion of the coating agent to the plastic surface resulting in high stability against physical effects such as friction etc.

- the coating is temperature resistant resulting in unproblematic thermoforming without impairing the antifog, antiblock or antistatic finish

- the slip properties of the plastic surfaces are improved by the coating

- striation-free highly transparent coating

- usable in the packing industry for foodstuffs according to EC-Directives

- MECOSTAT-3/722 is high yielding and therefore keeps down costs of antifog, antiblock and antistatic finish

- problem-free recycling of coated plastics

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Areas of Application

Antifogging, antistatic and antiblocking finishing of

- transparent thermoforming sheets

- transparent films for food packaging

- transparent films for packaging of farm products

- Mode of Antifog Operation

- The anti-fogging properties of a surface depend primarily on how hydrophilic the surface is and what surface energy it has.

- Water normally condenses on plastic surfaces in the form of tiny droplets, which refract the light in such a way that the surface appears opaque.

- If this surface is coated with MECOSTAT-3/722, the picture is completely different:

- The molecules of the antifog agent are partly hydrophilic, so that they dissolve in the water droplets or distribute them finely.

- This reduces the surface tension of the droplets, which causes the droplets to flow apart and form a uniform film on the surface.

- This fluid film refracts the light in a similar way to a dry surface, with the result that it is highly transparent.

- Processing Directions

- the following processes are suitable for coating: immersion bath, felting, roller application, application by flexographic or gravure printing, spray coating, rotor spraying coating (the

- appropriate processes are dependent on the application purpose)

- coating quantity: 2 to 5 g per sqm (wet coating amount)

- the coated surface must be completely dry before further processing or rolling up the sheet (if required, drying with warm air)

- If MECOSTAT-3/722 is applied on warm plastic surfaces, the surface temperature should not exceed 80 °C

- MECOSTAT-3/722 is supplied as a ready for use solution

- machine parts which come into contact with MECOSTAT-3/722 should be made of corrosion proof materials

- a combination of MECOSTAT-3/722 with antistatic additives is not recommended because of possible reactions

- depending on the particular application corona pretreatment is recommended (on Polyolefines and Polystyrene)

- due to the large number of applications and processing procedures we would like to point out that corresponding tests have to be performed by the customer to make sure that there will be no incompatibility with the raw materials, additives and the processing procedures

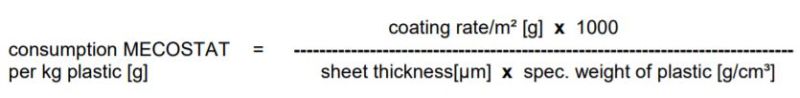

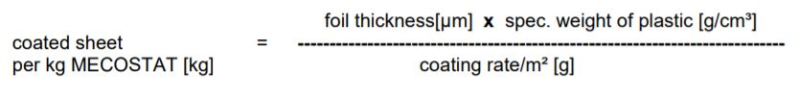

- Calculation of the consumption rate

Consumption rate of MECOSTAT-3 per kg plastic

Coated sheet per kg MECOSTAT-3

Typical value of spec. weights of different plastics

The exact specific weight depends on both, the plastic formula used and on the additives used. Therefore, the given values are only approximated values.

APET 1.35 g/cm³ PVC 1.42 g/cm³ PP 0.93 g/cm³ PETG 1.17 g/cm³ LDPE 0.95 g/cm³ HDPE 0.92 g/cm³ PS 1.10 g/cm³ ABS 1.12 g/cm³ PC 1.20 g/cm³ PTFE 2.16 g/cm³ PMMA 1.18 g/cm³ PUR 1.25 g/cm³

Properties

- Physical Form

Safety & Health

- Safety

MECOSTAT-3/722 as well as the raw materials contained in it comply and with the appropriate EC-Directives on the antistatic finishing of plastics in food packaging.

MECOSTAT-3/722 is environment-friendly and easily biodegradable.