Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

- Typical Properties of the Coating

- long-term antistatic finishing for several years with reduction of the surface resistance as far as 109 Ω at standard climatic conditions

- antistatic effect also at very low humidity (< 25%)

- strong adhesion of the antistatic agent to the plastic surface resulting in high stability against physical effects such as friction etc.

- the coating is temperature resistant resulting in unproblematic processing without impairing the antistatic treatment

- MECOSTAT-3/549 replaces antistatic additives

- no accumulation during recycling

- MECOSTAT-3/549 is highly productive (dosage from 1%, based on the EPS/EPP-weight)

- unproblematic recycling of the coated plastics

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Areas of Application

- high-quality antistatic finishing of technical products and electronic items as for example

- EPS/EPP-items for the taking of electronic items

- foamed parts for the packing of electronic modules and electronic devices

- EPS/EPP-packing chips

- EPS/EPP trays

- Processing Directions

The following different processes are basically available for the addition of the antistatic additive:

- Addition of the antistatic agents during pre-expansion in a continuous process via the steam line admission point or Mixing the plastic and the antistatic agent prior to the pre-expansion process in a batch mixer (e.g. at the same time as the special dye is added for dyeing the plastic)

- MECOSTAT-3/549 is supplied as a ready for use solution, if required, the product can be diluted with demineralised water

- machine parts which come into contact with MECOSTAT-3/549 should be made of corrosion proof materials but not from copper, aluminum and their alloys

- a combination of MECOSTAT-3/549 with other antistatic additives is not recommended because of possible reactions

- due to the large number of applications and processing procedures we would like to point out that corresponding tests have to be performed by the customer to make sure that there will be no incompatibility with the raw materials, additives and the processing procedures

- Process

Addition during continuous pre-expansion

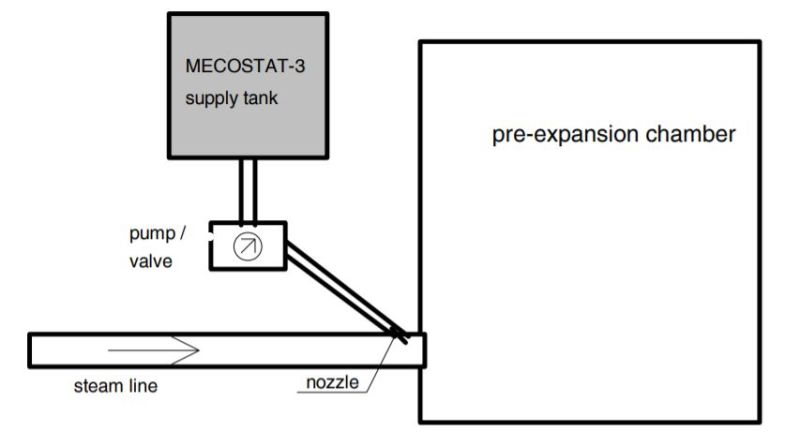

The antistatic agent is added into the steam line admission point during pre-expansion.

The antistatic agent can be dosed via a dosing pump or by liquid pressure, controlled by a needle valve, depending on the particular design of the system.

The added quantity of antistatic agent should be in the range 1 - 4 (weight-) %, referred to the throughput quantity of EPS/EPP, depending on the intended application.Schematic sketch of application

Addition prior to pre-expansion

This method is suitable both when using continuous pre-expanders and when using

intermittent pre-expansion of individual batches.

The antistatic agent is added to the EPS/EPP-raw material (not pre-expanded) in a batch mixer and is then mixed for a brief period.

If dyes are to be added, they must be added first and fixed. After fixing, the antistatic agent is added, whereby the dosage should be in the range of 1 to 4 (weight-) % (depending on the intended application and material type).

Properties

- Physical Form

Packaging & Availability

- Packaging Type

- Form of delivery and containers for antistatic agents used for EPS

Form of delivery : Ready for use, liquid solution

Container sizes : 20 ltr canister, 640 ltr IBC container, 1000 ltr IBC container