Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

- Typical Properties of the Coating

- longterm antistatic finishing for several years with reduction of the surface resistance as far as 1*108 Ω at standard climatic conditions

- antistatic effect also at very low humidity (< 15%)

- extremely low ion content (chlorides, sulfates, nitrates, phosphates), meets all the Class 1 cleanliness specifications for electronic packaging

- strong adhesion of the antistatic agent to the plastic surface resulting in high stability against physical effects such as friction etc.

- the coating is temperature resistant resulting in unproblematic thermoforming without impairing the antistatic finishing

- excellent wetting properties on plastic surfaces resulting in excellent antistatic finishing even under difficult thermoforming conditions

- the slip properties of the plastic surfaces are improved considerably by the coating, therefore improves the stackability of thermoformed parts

- no migration into the packed material, no accumulation during recycling

- striationfree highly transparent coating

- MECOSTAT3/247 is highly productive and keeps down costs of antistatic finishing

- unproblematic recycling of coated plastics

- MECOSTAT3/247 must not be used for food packaging,

- Environmental compatibility

MECOSTAT-3/247 is environment-friendly and easily biodegradable.

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Areas of Application

Antistatic finishing of

- special packaging for electronic items and devices

- thermoforming film (films up to 800 µm)

- other films and sheets

- molded, injection molded and hollow bodied parts

- profiles

- Processing Directions

- the following processes are suitable for coating: immersion, felting, roller application, application by flexographic or gravure printing (the appropriate processes are

- dependent on the particular purpose of application)

- coating quantity: depending on the application purpose 1.0 to 3.5 g per sqm (wet coating amount)

- the coated surface must be completely dry before further processing or winding the film (if required, drying with warm air)

- MECOSTAT3/247 is delivered as a ready for use solution (no dilution)

- MECOSTAT3/247 contains isopropyl alcohol, use explosionproof installations

- machine parts which come into contact with liquid MECOSTAT3/247 should be made of corrosionproof materials (not of copper, aluminum or alloys of them). The coating is not

- corrosive after drying.

- a combination of MECOSTAT3/247 with antistatic additives is not recommended because of possible reactions

- depending on the particular application a corona pretreatment is recommended (e.g., on some types of polyolefines and partially on polystyrene)

- due to the large number of applications and processing procedures we would like to point out that corresponding tests have to be performed by the customer to make sure that there will be no incompatibility with the raw materials, additives and the processing procedures

Properties

- Physical Form

Technical Details & Test Data

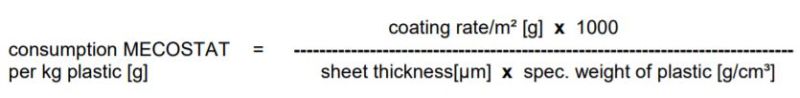

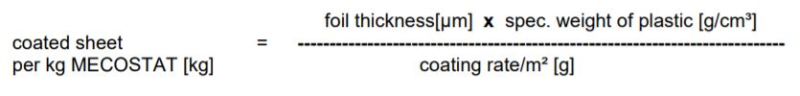

- Calculation of the consumption rate

Consumption rate of MECOSTAT-3 per kg plastic

Coated sheet per kg MECOSTAT-3

Typical value of spec. weights of different plastics

The exact specific weight depends on both, the plastic formula used and on the additives used. Therefore, the given values are only approximated values.

APET 1.35 g/cm³ PVC 1.42 g/cm³ PP 0.93 g/cm³ PETG 1.17 g/cm³ LDPE 0.95 g/cm³ HDPE 0.92 g/cm³ PS 1.10 g/cm³ ABS 1.12 g/cm³ PC 1.20 g/cm³ PTFE 2.16 g/cm³ PMMA 1.18 g/cm³ PUR 1.25 g/cm³