Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Fillers Included

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

- Graphene Nanofibers

Carbon Nanofibers is a material belonging to the family of graphene-based materials (GBM). We offer a fully characterized product with well-defined properties and high-quality standards aimed to help researchers of different fields to obtain reproducibility and replicability on their results and boost the outstanding potential of this material.

Features & Benefits

- Labeling Claims

- Materials Features

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Applications

First choice for demanding healthcare applications that require high structural stability. Some examples of possible applications are the following:

- 3D Printing Solution for custom orthosis: with a new, beautiful, ventilated design.

- Backing material to stable bone or other fractures, radiation oncology, prostheses, or foot inserts.

- Medical devices: connectors, catheters, flexible tubes, fluid, and air management.

The user responsible for the design must confirm the product requirements. The use of a given application must be previously tested by the user to determine its suitability.

- Recommendations for Use

- Processing temperature range: 196- 205 ºC. The processing temperature is directly related to the printing speed. The faster the processing speed is, the higher the temperature of the print fuser should be.

- Recommended bed temperature: 50-70 ºC. If the adherence to the building platform is weak, other products should be used to improve the adherence between the piece and the machine.

- Layer fan speed: 0%, not necessary.

- Heated chamber temperature: not necessary.

- It is advisable to use fully opened printers to ensure efficient cooling.

- Drying conditions: 65ºC for at least 4 hours. Due to the hydrophilic conditions of the thermoplastic polyurethane is recommended the complete material drying before its utilization.

- Printing speed: 20-40 mm/s. This parameter will depend on the final expected quality regarding the stability of the printing machine itself (if the speed is too high can cause bottlenecks, so this parameter has plenty of importance).

- Nozzle size: 0.4-0.6 mm, but smaller nozzles can be used if necessary.

Properties

- Color

- Physical Form

- Mechanical Properties

Value Units Test Method / Conditions Flexural Modulus 768.94 Mpa ISO 527 Elongation at Yield 4.8 - 5.2 % ISO 527 Elongation at Break 150 - 154 MPa ISO 527 Tensile Modulus 3.4 - 3.8 Gpa ISO 527 Tensile Strength 89 - 103 MPa ISO 527 - Typical Properties

Value Units Test Method / Conditions Specific Gravity 1.3 - 1.7 g/cm3 ASTM D792 Hardness 81 - 81.4 - Supplier’s method Layer Fan Speed 0.0 % - Nozzle Size 0.4 - 0.6 mm - Printing Speed 20 - 40 mm/s - Processing Temperature Range 196 - 205 °C - Recommended Bed Temperature 50 - 70 °C - - Other Properties

Value Units Test Method / Conditions Bed Temperature 50 - 70 °C - Injection Molding-melt Temperature 320 - 360 °C Supplier’s method Melt Flow 2.8 - 3.2 g/10 min Supplier’s method Softening Temperature VICAT 94 - 104 °C Supplier’s method Glass Transition Temperature 145 - 155 °C Supplier’s method Velocity 20 - 40 mm/s - - Material Specifications

Value Units Test Method / Conditions Taber Abrasion 75.0 mg loss - - Dimensional Properties

Value Units Test Method / Conditions Diameter 1.5 - 2.5 mm Manual measuring with Digital Caliper 0-100mm/0-4’’ Thickness 3 - 4 mm Manual measuring with Digital Caliper 0-100mm/0-4’’ Weight 650/3 g/K Balance - Material Properties

The main properties are:

- Improves the quality and the processability of the base polymer.

- High hydrophobic material that inhibits bacterial, virus, algae, or fungi growth.

- Top final quality with high brightness, pleasant touch, and suitable resilence (Shore 65D).

- Nanofiber blocks shrinkage, deformation, and layer lift, thereby provide structure and density that facilitate processability to produce complex geometries.

Regulatory & Compliance

- Certifications & Compliance

- Biocompatibility

- The original polymer meets the requirements of the FDA-modified ISO 10993, Part 1 “Biological Evaluation of Medical Devices” tests with human tissue contact time of 30 days or less and has been tested according to certain tests under ISO 10993-1.

- Tests performed on the polymer: Physicochemical Test for Plastics, Metals Analysis by ICP, Citotoxicity - MEM Elution (ISO 10993-5), Sensitization - Kligman Maximization (ISO 10993-10), Irritation - Intracutaneous Injection (ISO 10993-10), Material-Mediated Rabbit Pyrogen Test (ISO 10993-11), Hemolysis - Rabbit Blood (ISO 10993-4), Genotoxicity - Ames Reverse Mutation (ISO 10993-3) and Intramuscular Implantation (ISO 10993-6).

Technical Details & Test Data

- Antimicrobial Effect

- The antimicrobial effect of graphene-based materials has been widely demonstrated in various investigations. The graphene oxide and the graphene nanofiber are safe and has a high purity, in terms of contaminants such as sulfates or metals (such as iron or manganese), all of which have concentrations below <0,1%.

- The main mechanism of this effect is based to generate reactive oxygen species (ROS) agents such as H2O2, OH-, and O2 capable of destroying the respiratory system of microorganism and specifically attacks the lipid membrane of the coronavirus.

- Test Performed on 3D Printed Specimen

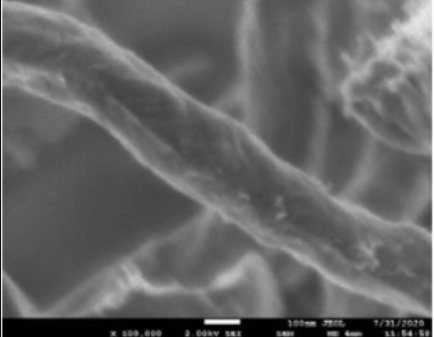

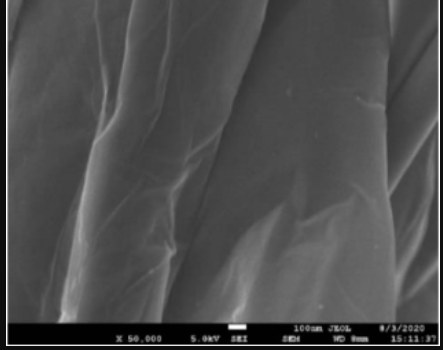

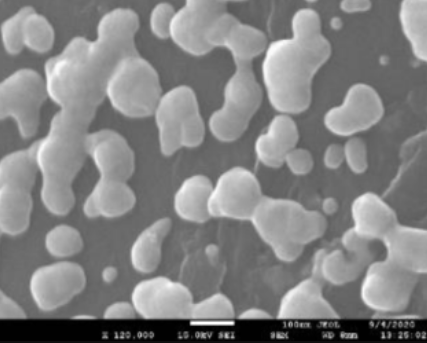

Upper and lower layer 3+3 Intermediate layer 3 Filling 100% Tensile Tester Specimen UNE EN ISO 527 1BA Flexural Test Specimen UNE EN ISO 168 (mm) 80x10x4 - Scanning Electron Microscope (SEM)

Graphene Nanofiber (GNF)

Graphene Oxide (GO)

Silver (Ag) + Graphene Oxide

Storage & Handling

- Shelf Life

- 5 years

- Storage Conditions

Store with desiccant in a cool, dry place. Keep container tightly closed in a dry and well ventilated place away from sources of ignition and oxidizers. Keep away from heat, sparks, flame and other sources of ignition. Store in accordance with the national regulations.