Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Features

- Low VOC –JIS A-1901

- Low FOG - VDA278

- Aggressive acrylic adhesive

- Good shear properties

- Moisture stable PCK liner

- Benefits

- Acid free, PH Neutral

- Non-outgassing and non-migratory

- Smooth adhesive profile

- Excellent adhesion to a wide variety of surfaces.

- Chemical & UV resistant

- Excellent handling and die-cutting.

- Non-corrosive & non-oxidizing

Applications & Uses

- Markets

- Applications

- Compatible Substrates & Surfaces

- Applications

- Insulation and Shielding

- Wire harnessing

- Foam bonding applications

- Interior applications that require low vOC and low FOG characteristics

- Flexible Printed Circuits

- Printed Circuit Boards

- Archiving, photo mounting

- Application Details

For best performance surfaces must be clean, dry and free of any oil, grease or other contaminant.

Properties

- Physical Properties

Value Units Test Method / Conditions Total Thickness 8.8 mils - Loop Tack (stainless steel) 5.0 lbs./in. PSTC-16-Method A Peel Adhesion (180° 2 mil PET Backed 30minute dwell, stainless steel) 8.5 lbs./in. PSTC-101-Method A Peel Adhesion (180° 2 mil PET Backed 24hours dwell, stainless steel) 9.9 lbs./in. PSTC-101-Method A Peel Adhesion (180° 2 mil PET Backed 30minute dwell, ABS) 8.1 lbs./in. PSTC-101-Method A Peel Adhesion (180° 2 mil PET Backed 24minute dwell, ABS) 7.9 lbs./in. PSTC-101-Method A Peel Adhesion (180° 2 mil PET Backed 30minute dwell, Polycarbonate) 8.8 lbs./in. PSTC-101-Method A Peel Adhesion (180° 2 mil PET Backed 24minute dwell, Polycarbonate) 8.2 lbs./in. PSTC-101-Method A Peel Adhesion (180° 2 mil PET Backed 30minute dwell, HDPE) 2.9 lbs./in. PSTC-101-Method A Peel Adhesion (180° 2 mil PET Backed 24minute dwell, HDPE) 3.2 lbs./in. PSTC-101-Method A Peel Adhesion (180° 2 mil dead soft aluminum foil, 30minute dwell, stainless steel) 9.5 lbs./in. PSTC-101-Method A Peel Adhesion (180° 2 mil dead soft aluminum foil, 30minute dwell, Polypropylene) 3.0 lbs./in. PSTC-101-Method A Shear (1 kg weight, 72°F) min. 85 hours PSTC-107-Method A Formaldehyde Content 0.4 µ g/m3 JIS-A 1801 Acetaldehyde Content 1.2 µ g/m3 JIS-A 1801 Xylenes Content 1.4 µ g/m3 JIS-A 1801 Fog 30.0 µg/g VDA278 Fog 0.11 mg SAE J1756

Regulatory & Compliance

- Certifications & Compliance

- Quality Standards

- Certifications

- JIS A-1901

- ISO 18916

Technical Details & Test Data

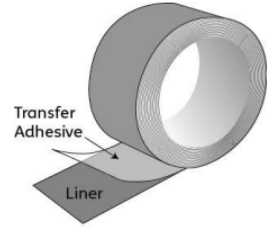

- Product Construction

- Adhesive: 3.0 mils LV820 LOW VOC Acrylic

- Liner: 80# Natural PCK or 72# White PCK

- Web Width: 54”

- Service Temperature

- Application : Above 50°F (10°C) for best performance

- End Use : -40°F to 300°F (-40°C to 121°C) depending on laminate construction and end use application

- Foam Bonding Performance

Substrate Application Method Result EPDM Room Temp with 50% compression Foam Destruction

Nitrile PVCc Room Temp with 50% compression Foam Destruction

EVA Blend Room Temp with 50% compression Foam Destruction

Polyether polyurethane Foam Room Temp with 50% compression Foam Destruction

NBR-PVC Room Temp with 50% compression Foam Destruction

Storage & Handling

- Shelf Life

Two year shelf life when stored at 75°F. (24°C.) and 50% relative humidity or less. It is recommended that the product be stored in its original package until ready to use.