Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Ingredient Origin

- Cleaning Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- HII Features

- Key Features

- Based on BioLoop technology

- 100% renewable

- No skin or eye irritancy

- No ecotoxicity

- Readily biodegradable

- Medium - High foam

- Good detergency

- A green alternative to alcohol ethoxylates

Applications & Uses

- Markets

- Applications

- Home Care Applications

- I&I Cleaning Applications

- Applications

Good detergency :

- Hard Surface cleaners and general cleaners. In formulations that contain alcohol ethoxylates then use BioLoop 68L as a green alternative. Also the SDS classifications will help ensure no hazard classifications.

Excellent substrate wetting on Nylon 6, Nylon 66 and Polycarbonates :

- Can be used in textile applications that contain Nylon.

Properties

- Physical Form

- Odor

- Characteristic

- Typical Properties

Value Units Test Method / Conditions Composition Bioloop surfactant alcohol ethoxylates - - Solids Content 78 - 82 % - HLB Value 13.2 - - Viscosity (at 25°C) 509.0 cPs - Pour Point 18.5 °C - Specific Gravity (at 20°C) 1.08 - - Flash Point min. 150 °C - Surface Tension (0.1% Aqueous) 36.5 mN/m - - Specifications

Value Units Test Method / Conditions Color (Gardner) max. 5 - -

Technical Details & Test Data

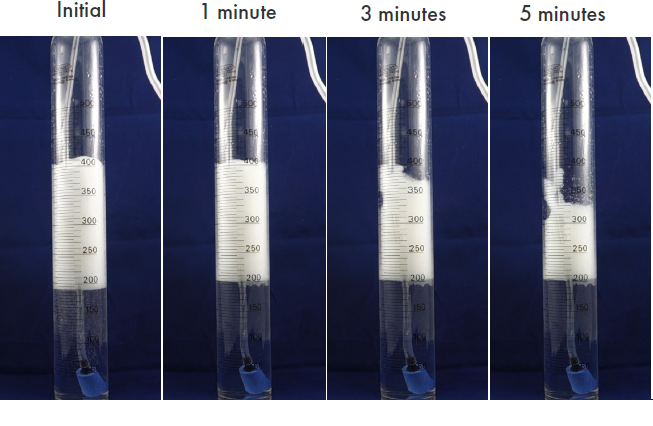

- Foaming Profile

Test method : A 0.1% solution is prepared and aerated for 30 seconds and then stopped. The degree of foaming is assessed initially and then after 1, 3 and 5 minutes.

Conclusion : When compared to our full range of surfactants would be classed a MEDIUM foam surfactant.

- Detergency Testing

Test method : A formulated soil is applied to a painted disk and then aged in an oven. The disk is then soaked in a detergent solution for 10 minutes and then rotated for a further 5 minutes. The % soil removal is then measured.

No Detergent

BioLoop 68L

Results :

No Detergent BioLoop 68L % Soil Removal 20.1% removal 77% removal - Substrate Wetting

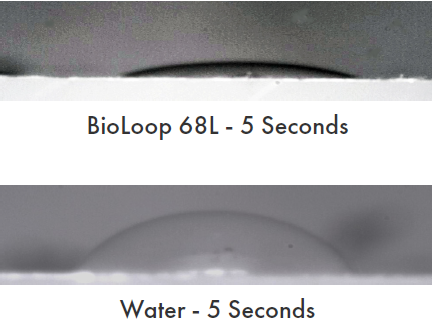

Test method : A 0.5% solution is prepared and is dropped onto various substrates. The contact angle is then measured using a goniometer. The angle is measured initially and then after 5 seconds. The lower the angle the better the product wets the substrate.

Nylon

Sample Contact Angle Initial Contact Angle - 5 sec

Water 46 45 BioLoop 68L 17 8