Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Catalyst Type

- Chemical Family

- Reaction Phase

- CASE Ingredients Functions

- Industrial Additives Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- CASE Ingredients Features

- Advantages

- Excellent replacement for tin catalysts

- Can be used in ambient, force dry and bake systems

- Excellent gloss retention

- Excellent exterior durability

- Improved hydrolytic stability compared to other bismuth carboxylates

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Coating Type

- Use Level

- 0.1 - 0.5% (as supplied on total resin solids for 2-component polyurethanes), 1 - 2.5% (as supplied on total resin solids for blocked isocyanates)

- Applications

- K-KAT XK-651 is recommended for 2K and blocked isocyanate coatings.

- K-KAT XK-651 can replace many heavy metal and/or toxic catalysts used in the production of urethane elastomers, foams and coatings.

- Incorporation

K-KAT XK-651 can be added directly to a single component blocked isocyanate system or the polyol component of a 2K system.

Properties

- Color

- Physical Form

- Appearance

- Clear, Amber liquid

- Typical Properties

Value Units Test Method / Conditions % Metal 25 % - Specific Gravity (25°C) 1.2 - -

Technical Details & Test Data

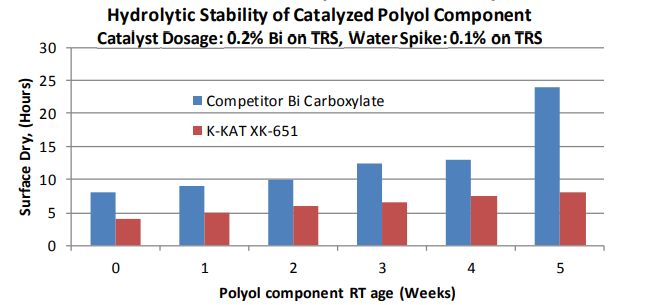

- K-KAT XK-651 Improved Hydrolytic Stability vs. Competitor Bismuth Carboxylate

The graph below demonstrates improved stability with K-KAT XK-651 compared to a competitive bismuth catalyst in a 2-component urethane system. The graph includes surface dry times of films prepared with catalyzed polyol components that were aged for 5 weeks. The catalyst dosages were based on equal bismuth content on total resin solids (0.2% Bi), and the systems were spiked with 0.1% water based on total resin solids. The results show only a slight increase in the surface dry times of the films prepared with the aged K-KAT XK-651 catalyzed polyol components while the surface dry times of the films catalyzed with the competitor bismuth carboxylate increased significantly.

Polyol Componnt Weight % K-FLEX® XM-359 38.9 PM Acetate 29.95 Flow and leveling agent 0.14 Water 0.07 Isocyanate Component

Hexamethylene diisocyanate biuret 30.94 100 Formulation Characteristics

NCO:OH 1.04 %water spike on total resin solids 0.1 Total Resin Solids, % 69.8 K‐KAT®XK‐651 vs. Competitor Bi Carboxylate

Storage & Handling

- Shelf Life

- 24 months

- Storage/Shelf Life

- Safe handling of this product should include the use of a respirator, safety glasses and gloves.

- Avoid breathing vapors - use with adequate ventilation.

- K-KAT XK-651 is sensitive to moisture, therefore, exposure to atmosphere during storage should be avoided.

- Product should be stored in a cool, dry environment away from sunlight and excessive heat.

- 24 months from the date of manufacture, when stored at ambient conditions in the original container.