Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Cleaning Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- HII Features

- Advantages

- To intensify and accelerate chemical cleaning processes.

- Sugar degradation products and other organic ingredients (e.g. protein and other gelatinous substances) are dissolved considerably better and faster in alkaline solutions.

- In alkaline pretreatments, the transformation of hardly soluble Ca-compounds (such as calcium sulfate (gypsum), calcium oxalate, calcium silicate, etc.) into acid-soluble compounds is greatly promoted by the addition of KEBOSOL VD, thus significantly shortening the treatment time.

- In the case of intermediate rinsing, detached sludge is better removed and thus the acid requirement is considerably reduced.

- Product Highlights

- Emulsifies greasy and oily components (e.g. foam oil residues).

- Disperses fine layers of dirt.

- Is stable and effective even at high temperatures.

- Can be used with alkali concentrations of up to approx. 25%.

- In the case of alkaline pretreatments, the conversion of poorly soluble Ca compounds (such as calcium sulfate (gypsum), calcium oxalate, calcium silicate, etc.) into acid-soluble compounds is greatly promoted. Thus shortens the treatment time significantly.

- Sludge that has been detached is better removed during intermediate flushing.

- Reduces the acid requirement considerably.

- During the alkaline post-treatment, the digestion of acid-insoluble silicates and organic substances is intensified.

- Favors the removal of acid residues.

- Supports the neutralization of acid residues in the after-treatment even in the smallest pores and hairline cracks due to the good wetting properties.

- Improves the removal of sludge residues during the final rinse.

Applications & Uses

- Markets

- Applications

- Applications

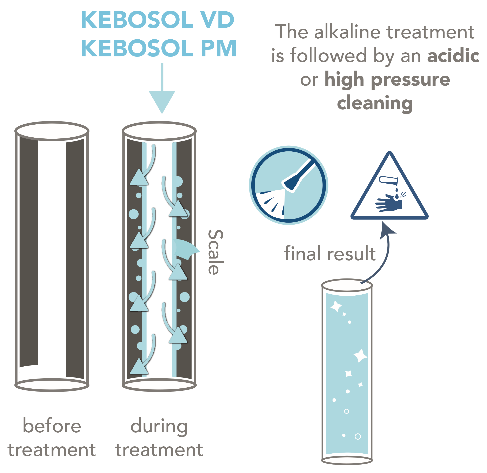

- To intensify and accelerate chemical cleaning operations. KEBOSOL VD consists of a specific combination of detergent surfactants which have an excellent cleaning efficiency in neutral and alkaline solutions already at very low dosing rates. KEBOSOL VD emulsifies fatty and oily substances (e.g. residues of antifroth oils) and disperses thin films of dirt. Thus redeposition and adhesion to the heat surfaces are prevented.

- During chemical cleaning operations in the sugar industry the following advantages have proved a success when adding KEBOSOL VD:

- The detachment of sugar decomposition products and other inconvenient organic components (e.g. proteins and other gelatinous substances) is considerably improved in alkaline solutions.

- At alkaline pretreatments calcium compounds (such as calcium sulfate (gypsum), calcium oxalate, calcium silicate a.s.o.) being difficult to dissolve are transformed into acid soluble compounds by adding KEBOSOL VD. As a result the treatment period is shortened.

- At intermediate cleanings the removal of detached sludge is improved. Consequently the requirement of acid is considerably reduced.

- During the alkaline aftertreatment the decomposition of acid insoluble silicates and organic substances is intensified and the removal of acid residues is favored. This is of utmost importance as even small acid residues remaining in the smallest pores may cause serious corrosion. The addition of KEBOSOL VD to alkaline solutions supports the neutralization of acid also in the smallest pores and crazings owing to its good wetting properties. At the final rinsing the removal of residual sludge is improved.

- KEBOSOL VD is even resistant to high temperatures and effective and can be used for alkali concentrations up to approx. 25 %.

- Addition and Dosing

- KEBOSOL VD is added either when preparing the alkaline solution in the mixing tank or directly into the apparatus filled with alkaline solution ready for use.

- The dosing rates amount to:

- Alkaline pretreatment of apparatus with normal contamination (up to 5% total alkali content) 0.1 - 0.2%

- Alkaline pretreatment of apparatus with thick contamination (more than 5% total alkali content) 0.2 - 0.5%

- Alkaline aftertreatment/neutralization (up to 2 % total alkali content) 0.1%

- The duration of treatment depends on the composition and thickness of scales as well as on the application temperature. Detailed instructions for each individual cleaning can be elaborated by us.

- Systems treated with KEBOSOL VD have to be rinsed with water until they are free from residues before the sugar juice will flow again through these tubes.

- Areas of Application

Activator for alkaline and neutral solutions. For intensifying and accelerating chemical cleaning processes.

- Remove / Protect Coatings

Emulsifies greasy and oily components (foam oil residues).

- Material

In neutral and alkaline solutions

Properties

- Appearance

- Slightly yellowish, slightly cloudy liquid

- Typical Properties

Value Units Test Method / Conditions Density (at 25°C) approx. 1 g/cm³ - pH Value (100 g/l water) 10.8 – 11.4 - -

Regulatory & Compliance

Technical Details & Test Data

- Technical Details

- Operating Temperature

High temperatures

Packaging & Availability

- Packing

- 60 kg cans

- 200 kg barrels

- 1000 kg containers

Storage & Handling

- Shelf Life

- 2 Years

- Storage

In closed original packages KEBOSOL VD is storable for at least two years. Protect from frost.