Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Features

- LDS additives have a double function – they work as a laser marking additive and as a catalyst for the metallisation process.

- The specific advantages of the StanoStat additives are their light colouration and high stability.

- Product Highlights

- Laser marking produces permanent and indestructible marks on plastic surfaces, and these permanent marks offer many advantages over other markings. To name just a few: improved quality control, brand protection against product piracy, and stability against environmental impact.

- Laser marking is a very flexible technology, suitable for high volume products, as well as for small lot sizes. The abrasion resistant laser marks can be applied on soft or hard surfaces, and even on surfaces which are not flat. Marking in all 3 dimensions is possible.

- Whether it is for technical applications like bar codes and lot numbers, or for decorative purposes, the laser marking process is a good choice for those looking for a lasting solution.

- However, not all polymers mark the same way. Some polymers like PE or PP are almost transparent for the typically used near infrared lasers with a wavelength around 1064 nm. Others, for example, PC, interact easily with NIR laser light without any additives.

- As a result, the use of laser marking additives is necessary in many polymers to achieve a good laser marking result.

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Coating Type

- Ink & Toner Type

- Plastics & Elastomers End Uses

Properties

- Physical Form

- Typical Properties

Value Units Test Method / Conditions Color Measurements (L Value) 35 - 55 - - Loss on Ignition (at 1000°C in air) 2.5 % - - Specifications

Value Units Test Method / Conditions Surface Area 10 - 30 m²/g BET Reflectance (at 1000nm) max. 15 % - Bulk Density 1500 - 2200 g/l - Tap Density 2000 - 3000 g/l - Water Update (per 2g sample) max. 0.2 g -

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Product Information

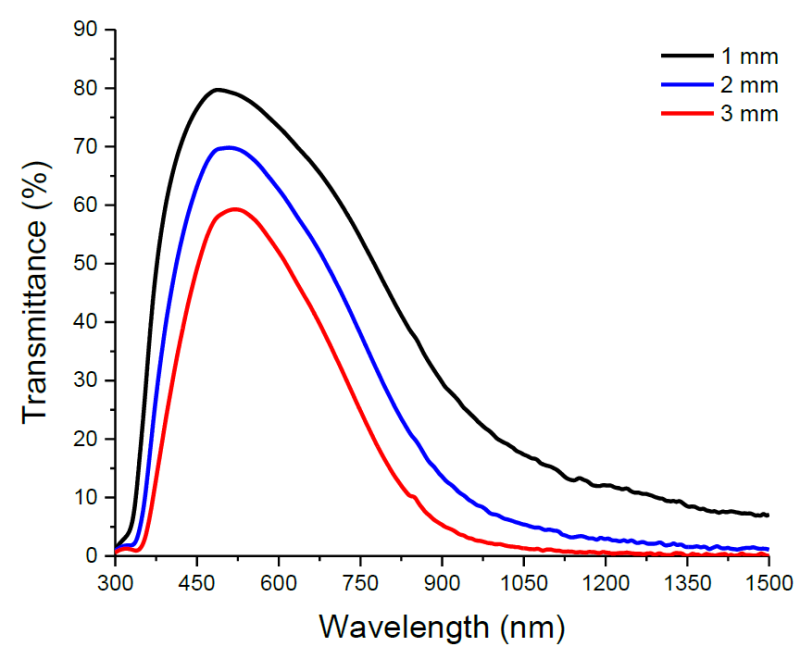

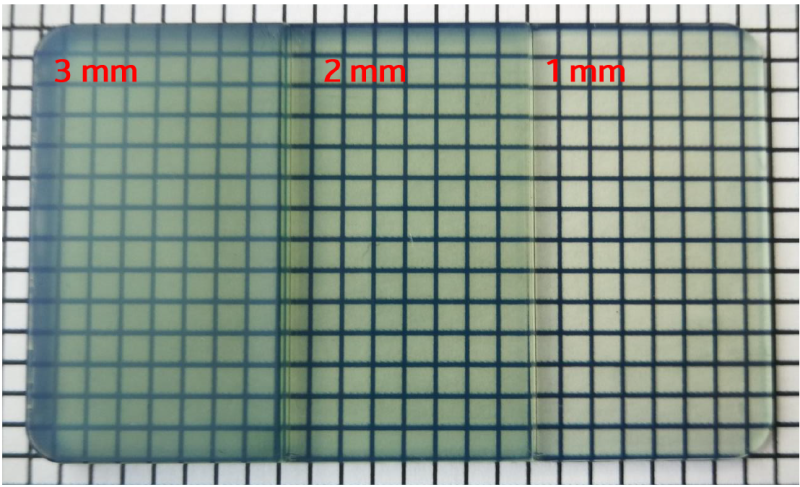

0.1 wt.% IRASORB BITO in polycarbonate @ 1, 2 and 3 mm thickness

Optical Properties

Plaque Thickness (mm) UV T(%) VL T (%) IR R (%) SHGC (%) 1 13.1 64.9 83.2 0.46 2 2.7 46.8 95.7 0.29 3 0.6 33.6 98.9 0.20 T= transmittance

R=rejection

SHGC= Solar Heat Gain CoefficientTransmittance Curves