Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Core Type

- Composite Materials Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Advantages

- Excellent Strength-to-Weight ratio

- Foam Reinforced with fiberglass increases mechanical properties

- Lightweight - 30% Lighter Than Marine Plywood

- Closed Cell Cross-Linked Polymer Foam will not absorb water

- Will Not Rot...Excellent Replacement for Wood

Applications & Uses

- Markets

- Applications

- Composites End Use

- Composites Processing Methods

- Applications

- Boat Transom

- Boat Stringers

- Boat Bulkheads

- Boat Decking

- Boat Structural Fabrication

- Ice Decking

- Deerblind Flooring

- Substation Houses

Properties

- Typical Properties

Value Units Test Method / Conditions "R" Factor (for 1" (x2-2")) 2.78-2.50 - - Coefficient of Linear Expansion 4 105in/in/°F ASTM D696 Compressive Modulus 22300 psi - Compressive Strength 890 psi - Density 208 - 288 kg/m³ - Dielectric Constant 1.3 - ASTM D1673 Dissipation Factor (at 20°C and 1 meg) 0.0055 - - Flexural Modulus 36200 psi - Flexural Strength 1170 psi - K" Factor Thermal Conductivity 0.36-0.40 BTU/ft2/hr/°F/in ASTM D2326 Max Service Temperature 93 °C - Shear Modulus 4300 psi - Shear Strength 350 psi - Tensile Modulus 18000 psi - Tensile Strength 640 psi - Water Absorption (by vol. (96 hrs)) 0.4 % ASTM D2842

Technical Details & Test Data

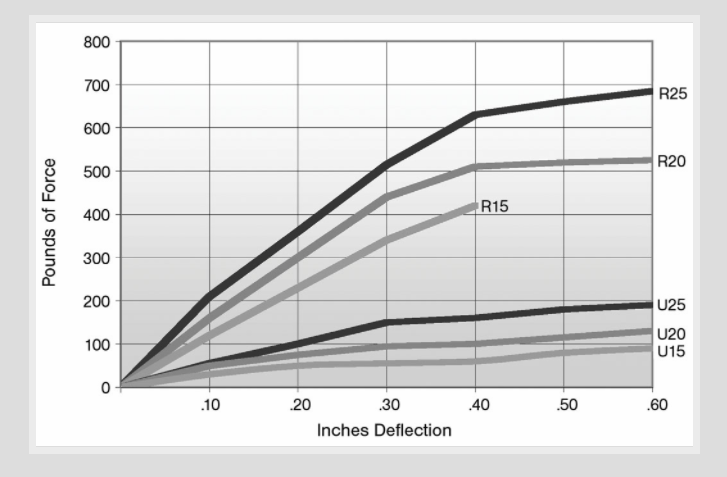

- Flex Test Chart

U20 -Unreinforced 20 lb/ft3 (320 kg/m3) Material

Tests were performed on a 17" (431.8 mm) long and 1-1/2" (38.1 mm) thick KAY‑CEL samples with the above physical properties.

The chart above shows how Fiberglass reinforcement increases the strength of KAY‑CEL CORE by 300%.

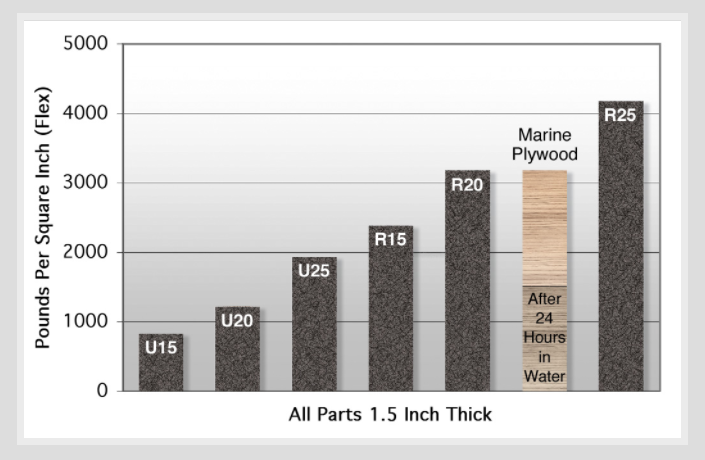

- Water Absorption Test

The chart above shows how marine plywood loses 60% of its strength after being submerged for 24 hours

Storage & Handling

- Handling Information

- Store Kay-Cel Core material indoors or protect from sunlight.

- Can be cut with normal woodworking tools.

- Wear dust mask, eye protection, and gloves when cutting.

- Can be use with a wide variety of resins.

- Do Not burn material.

- Best practices:

- Maintain dry, clean surface for maximum bonding.

- Pre-wet boards with resin before applying fiberglass.

- Remove any release agensts or shiny spots before bonding.