Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Ingredient Name

- CASE Ingredients Functions

- Industrial Additives Functions

- CAS No.

- 9004-65-3

- Ingredients

- Hydroxypropyl Methyl Cellulose (HPMC)

- Food Additive Number

- E 464, INS 464

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- CASE Ingredients Features

Applications & Uses

- Markets

- Applications

Properties

- Physical Form

- Odor

- Neutral

- Flavor

- Neutral

- Appearance

- White, Powder

- Physico-Chemical Properties

Value Units Test Method / Conditions Assay for Hydroxypropoxyl Groups* 2021-12-04 % - Assay for Methoxyl groups* 19 - 24 % - Insoluble in Ethanol - - Loss on Drying max. 5 % - Molecular Weight 13,000 - 200,000 - - pH-value 5 - 8 Solubility Swelling in water, Producing a Clear to Opalescent, Viscous, Colloidal solution - - Sulphated Ash Content max. 1.5 % - Viscosity 11,250 - 21,000 mPa.s USP-Method - Microbiological Values

Value Units Test Method / Conditions Total Plate Count max. 1 x 10³ cfu/g - Yeasts and moulds max. 2 x 10² cfu/g - - Heavy Metals

Value Units Test Method / Conditions Arsenic Content** max. 3 mg/kg - Cadmium Content ** max. 1 mg/kg - Lead Content** max. 2 mg/kg - Mercury Content** max. 1 mg/kg - Propylene Chlorohydrins** max. 0,1 mg/kg - - Note

* the substituents were determined by gas chromatography

**monitoring

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- JRS Hydrocolloids – Thermal Reversible Cellulose Ether Gels

Thermal Reversible Cellulose Ether Gels

Hydroxypropylmethylcellulose (HPMC) is a modified cellulose ether and appears as whitish powder in dry state. The degree of substitution (DS) and the methyl/hydroxypropyl ratio as well as the degree of polymerization define the characteristics of various grades. Cellulose ethers are generally soluble in cold water and yield clear solutions in a wide range of viscosity from 5 to 60,000 mPa·s (2 % w/w at 20 °C). HPMC is frequently used as rheology modifier, protective colloid in PVC production, water retention aid, pharmaceutical coating agent and more.

JRS HPMC Core Benefits

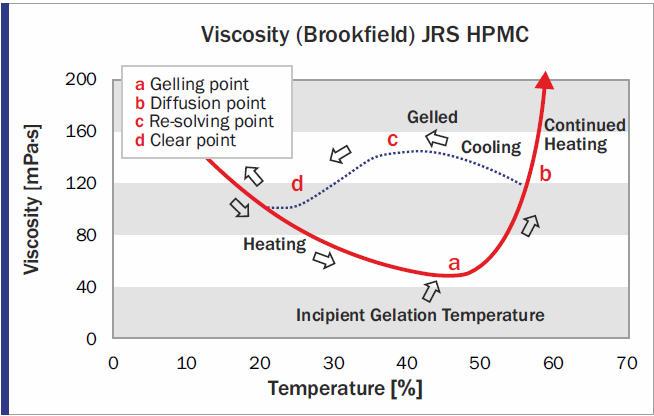

HPMC is typically used in dosages of 1-3 % (w/w) in aqueous systems. The clear solutions show thermal reversible gelation behavior (Pic. 1), where gelation temperature and resulting gel strength can be adjusted through available grades. Hydrophobic effects of the methoxyl groups facilitate thermo-reversible gelation. At lower temperatures, water molecules form enclosed structures around the hydrophobic groups, which disintegrate upon heating.The subsequently exposed methoxyl groups form hydrophobic aggregates, which are the reason for the gelation process (Graph. 1). HPMC is not very sensitive

towards pH and stable between 3 and 11.

Pic. 1: HPMC gels.

The good compatibility with synthetic or natural polymers like PVOH, starch, xanthan or guar and many more is proven. Whereas very high salt concentrations can cause flocculation of the product.

JRS HPMC products are also suitable as film forming agents. Their transparent and flexible films exhibit certain tackifying effects. This stickiness can be exploited to adapt coating properties in green and finished state. Additionally, HPMC films form an

effective oil barrier with the KIT level 12.

Graph. 1: Thermal reversible gelation curve of typical HPMC grades.

Storage & Handling

- Shelf Life

- Atleast 3 Years

- Storage

- Store at room temperature in dry conditions. In original and unopened bags, best before at least 3 years starting with production date