Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Chemical Resistance

Good

Applications & Uses

- Markets

- Applications

- Application Method

- Cure Method

- EtO And Gamma Sterilization

All Incure medical products are formulated to subject to standard sterilization methods, such as EtO and Gamma Radiation of 25 to 50 kGrays (cumulative). Enhanced moisture and

thermal resistance of this product show excellent adhesion and bonding strength after one cycle of steam auto-clave test. Depending on bond design and structure of the application,

users should test specific assemblies after subjecting them to sterilization. Consult Incure Support Team for assistance, if your devices are subjected to more than one sterilization cycles.

Properties

- Color

- Appearance

- Single Component, Slight Yellow Tint, Fluorescing

- Cured Properties

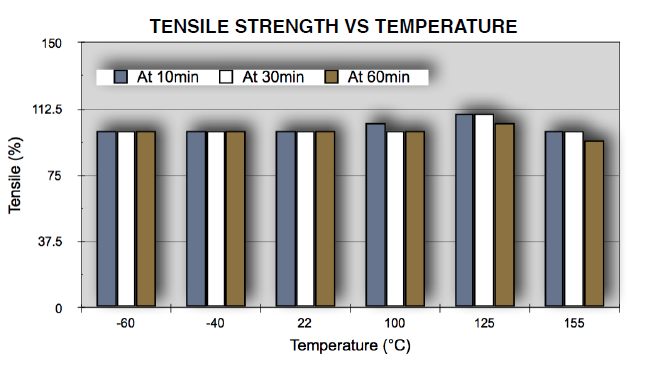

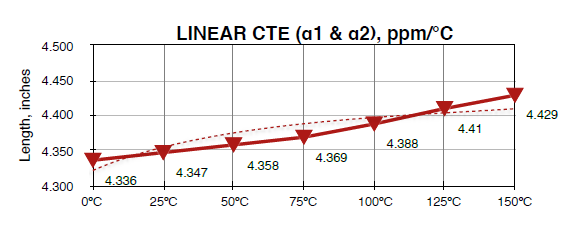

Value Units Test Method / Conditions Elongation at Break 74.0 % ASTM 638 Hardness (Durometer) 35 to 45 Shore D ASTM 2240 Linear CTE (α1) 44.0 ppm/°C ²ISTM D696 Linear CTE (α2) 80.0 ppm/°C - Linear Shrinkage / Expansion (-ve) 2.16 % ASTM D2566 Surface After Full Cure Sleek - ²ISTM D189 Tensile (PC-AL) Good psi ASTM 638 Tensile (PC-PC) Good psi ASTM 638 Tensile (PC-S) Good psi ASTM 638 Tensile (PC-SS) Good psi ASTM 638 Thermal Range (Brittleness / Degrades) -55 to 150 °C ²ISTM D366 Water Absorption (24hrs) 0.01 % ²ISTM D570 - Uncured Properties

Value Units Test Method / Conditions Density 1.03 g/ml - Flash Point min. 93 ºC - Refractive Index (20°C) 1.48 - - Toxicity Low - - Viscosity (20 rpm) 300 - 400 cP - - Note (Cured Properties)

Other viscosities are available upon request. If the viscosity range requested is not our standard offering, this product may be produced with a small lab fee. ASTM D2556 1 Viscosity (cP) taken at 25ºC - Call to enquiry for other viscosities.

- Note (Uncured Properties)

2. ISTM - refers to Incure Standard Test Method.

3. ASTM 638 Young’s Modulus test speed @5mm/min for rigid and semi-rigid materials, at 50mm/min for non-rigid materials, unless otherwise specified.

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Recommended UV Cure Schedule (Full Cure)

Cure times on 8mm ø adhesive sample. Belt speeds using C9000-F200Px1AB (Flood) and C9000-F500x1AC (Focused Beam) conveyors for area curing. Please consult IncureLab™ for any other requirements.

UV Intensity Reference Table

Incure UV Curing Lamp Model ⁴Curing Distance vs UV Intensity Spot Curing (Diameter) 0.5” (12.6) 1” (25.4) 1.5” (38) 2” (50.8) 2.5” (63.5) 3” (76.2) S20™ ARC (mW/cm2) / (ø mm) 1,400 (3) 1,500 (4) 650 (6) 360 (8) 240 (10) 175 (12) L9000™ LED (mW/cm2) / (ø mm) 7,500 (9) 5,000 (10) 2,300 (17) 1,200 (20) 700 (25) 450 (30) Flood/Focus Beam (Area) UV Intensity (mW/cm2) F200™ ARC Flood (6” x 8”) 325 280 245 215 190 165 F400™ ARC Flood (4” x 4” ) 860 570 440 345 270 215 F500™ ARC Focused (3” x 5” ) 1040 685 530 415 325 260 L1044-365™ LED Flood (4” x 4”) 2675 2380 1900 1625 1430 1280 L1044-405™ LED Flood (4” x 4” ) 2950 2625 2150 1900 1650 1450 ⁴Curing Distance is defined by the tip of light-guide or base of lamp housing to the bond area. All values are nominal with ±10% variation, with LED Flood Static Uniformity at ±78% and Dynamic Uniformity at ±90%. Recommended curing parameters in gray.

UV Curing Schedule For This ProductWavength λ UVA (320 - 400nm) UVB (290−320nm) UVC (290-220nm) VUV (400-700nm) Note: This product has been thoroughly tested to cure with F200P™ UV Flood Lamp.

Intensity wavelengths (shaded) are crucial for curing this product. All measurements

are made with EIT UV PowerPuck II. If you are unable to fully cure this product for

some reasons, pls email us for assistance with your curing information.Minimum Intensity 223 mW/cm2 56 mW/cm2 4 mW/cm2 215 mW/cm2 Total Energy Required 8,920 mJ/cm2 2,240 mJ/cm2 152 mJ/cm2 8,600 mJ/cm2 - Technical Details

Secondary Heat Cure (Not Applicable)Continuous Oven Bake Duration 95°C (203°F) 120 mins 110°C (230°F) 60 mins 125°C (257°F) 30 mins

Storage & Handling

- Storage and Shelf Life

Shelf−Life of this unopened product is a minimum of ONE (1) year from date of manufacture. Avoid direct exposure of bottle to visible light at all times. Containers should remained

covered when not in use. Product should be stored in a dark cool place of 10°C to 32°C. Transfer of product into other packages void all warranties. Users should ensure all bonding

surfaces are free of grease, mold release, or any contaminants, as bonding performance will be compromised. All tests for cured bonds should be carried out at ambient temperature. For

safe handling of this product, please read Material Safety Data−sheet (MSDS) prior to use. Organic solvents, such as IPA, may be used to wipe away uncured material from surfaces.