Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Name

- Country of Origin

- INCI Name

- Ingredient Origin

- Cleaning Ingredients Functions

- Cosmetic Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- Benefit Claims

- Labeling Claims

- HII Features

- Product Features & Benefits

- It might come with a foam layer on top which is chemically identical with the solid product.

- The product can be cut or scooped easily and melts between 50- 60°C.

- 100% Renewable

- Bio-based Surfactant category 1 according EN 17035

Applications & Uses

- Markets

- Applications

- Application Format

- Home Care Applications

- I&I Cleaning Applications

- Skin Care Applications

- Formulation Guidelines

Oil Component (Liquid oils,Vegetable oils, Emmolient) + EasyTens® X1 (Pasty & Cloudy) = Gel/ Solid (Transperant, Gelly-like or Solid)

- In order to incorporate EasyTens® X1 into the oil it is recommended to melt it at 60-80°C until it turns into a homogeneous liquid.

- Optionally it can be allowed to cool down again to approximately 35°C while stirring.

- The viscosity will increase but EasyTens® X1 will not completely solidify as long as shear forces are maintained.

- This allows for the use of rather heat-sensitive ingredients to be incorporated as well.

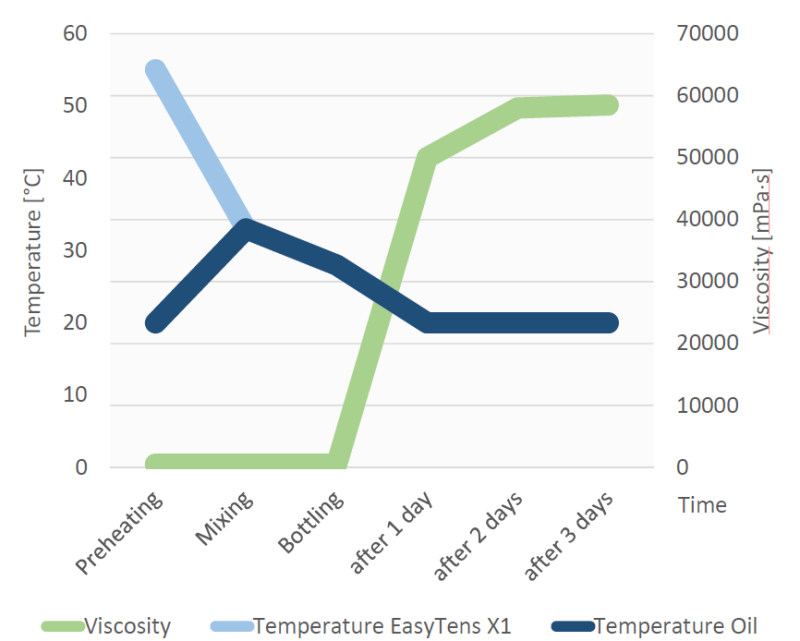

Temperature Profile

Heating of other components is not necessary but can be performed if for example oils with a higher melting points are being used such as coconut oil or shea butter. Mixing at elevated temperatures does not change the final hardness of the product but might lead to a delay in the viscosity build-up.

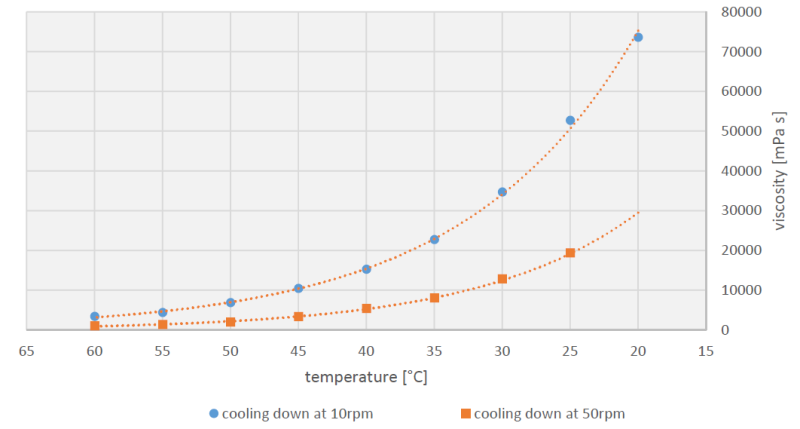

Temperature dependency of the viscosity of preheated EasyTens® X1

Figure 1: Dynamic viscosity of EasyTens® X1 at different temperatures. Recorded on a Rheomat R180 with measurement system 33 according to DIN 53018.

Note: Avoid any unnecessary exposure of EasyTens® X1 to elevated temperatures as it might lose the thickening properties if heated for an extended period of time. Always store cool at 25°C or below.

Viscosity Behavior of the Formulation

A first increase of the viscosity can be observed within minutes to hours after bottling. The final hardness of the product is reached after approximately three days in storage without agitation. When the final hardness has been reached the formulation stays solid up to temperatures of 40°C. When applying the product the combination of body heat and gentle rubbing will turn the jelly back into a free flowing oil which can be dispersed on the skin without effort.

Modifying the Viscosity

In most formulations the addition of EasyTens® X1 leads to solid products. A reduced concentration of EasyTens® X1 will not lead to oils with an increased viscosity but will reduce the hardness of the obtained jelly. However it is possible to obtain a free flowing viscous oil by addition of HYDRIOL® PGMO.4.

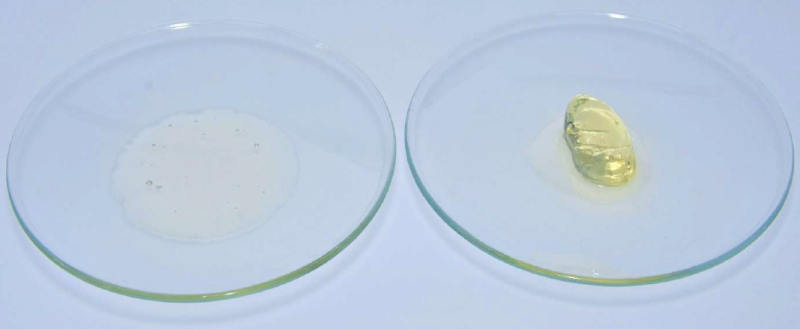

The addition of 1-2% of HYDRIOL® PGMO.4 leads to softening of the oil jelly, further increase to 3-4% will turn it into a granular viscous liquid. An example formulation where this behavior is observed is shown in figure 2.

Figure 2: Formulation containing 15% EasyTens® X1 in rapeseed oil with 3% HYDRIOL® PGMO.4 (left) and without additional HYDRIOL® PGMO.4 (right)

- Soft Jelly HYDRIOL® PGMO.4: 1 - 2 %

- Flowable Granular Liquid HYDRIOL® PGMO.4: 3 - 4 %

Dosage and Use

The typical dosage of EasyTens® X1 is between 10-20% of the final formulation depending on the desired hardness of the final product and on the overall composition of the formulation. Components that contain many polar functional groups typically tend to reduce the hardness of the final product. It is advised to increase the concentration of EasyTens® X1 in such cases to make up for the loss in hardness.

In some cases concentrations below 10% can be considered but might lead to a slight loss of transparency of the formulation. Due to the excellent emulsifying properties of EasyTens® X1 formulations containing more than 15% can be simply rinsed of with water leaving a smooth skin feel without stickiness or greasiness.

- EasyTens® X1: 10 - 20%

- Oil: 80 - 90 %

- Lower Limit approx.: 5 % of EasyTens® X1, low viscosity, cloudiness at < 5%

- Upper Limit: no limitation, formulation gets sticky and gummy

Selection of the Main Oil Component

A list of suitable oils which are easily thickened by EasyTens® X1 is given in the first column of table 1. The second column lists oils that have been found unsuitable main oil component of a formulation but might still be incorporated as minor ingredient up to 20% for certain compounds (e.g. Isopropyl Myristate).

Suitable (thickenable) Unsuitable (non-thickenable) Sunflower Oil Castor Oil Olive Oil Silicon Oil Almond Oil Paraffinum Perliquidum Sesame Oil Hemp Oil Avocado Oil Isopropyl Myristate Rapeseed Oil Isopropyl Palmitate Caprylic / Capric Triglyceride Decyl Oleate Jojoba Oil Argan Oil Macadamia Oil Rosemary Oil Dicaprylyl Carbonate Squalane Coconut Oil* Hydrogenated Polyisobutene Octyldodecanol Table 1: List of suitable and unsuitable oils

*Coconut oil which usually appears as a butter falls in line with the other suitable oils by the addition of 20% EasyTens® X1 forming a transparent jelly. In the case of shea butter transparency was not achieved but a much smoother texture was observed.

Mixing and Bottling

Many different active ingredients can be incorporated into a formulation containing EasyTens® X1 including polar compounds and even watery extracts in small amounts of up to 1%. Such ingredients might reduce the final viscosity of the product which can again be adjusted by increasing the concentration of EasyTens® X1. In most cases the transparency is not affected due to the inherent emulsifying properties of EasyTens® X1.

The oil is premixed with all active ingredients and added to the liquefied EasyTens® X1 while stirring or vice versa. No thickening will occur as long as the formulation is being stirred. The finished formulation can be bottled in liquid state at low or high temperatures and will solidify when allowed to rest for several days.

Effect Elements

The solid form allows to formulate applications with effect elements. The elements should not be coated with some glycolic substance.

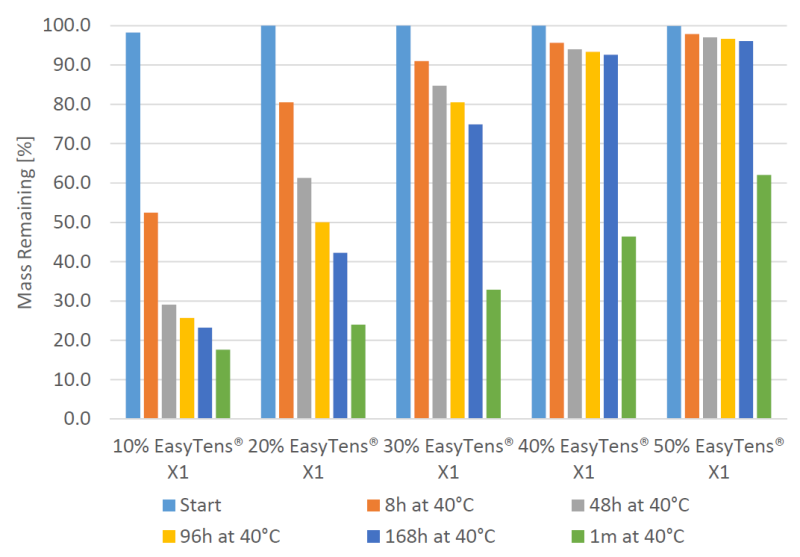

Heat Stability

EasyTens® X1 can be heated to 50-80 °C for a short period of a few hours without any loss of quality. EasyTens® X1 should be stored at max. 25 °C. Longer storage at Temperatures above 25 °C will result in a loss of performance.

Hygroscopy

EasyTens® X1 is hygroscopic and tend to bind water in its pure form.

Exudation, Syneresis

Solidifies oils with EasyTens® X1 tend to expulse the oil from the solid gel form.

Exudation of Oil Cubes with Sunflower Oil

Properties

- Physical Form

- Appearance

- Gelatinous yellowish to yellow-brown clear to slightly cloudy solid

- Odor

- Characteristic

- Typical Properties

Value Units Test Method / Conditions Saponification Value 110.0 - 150.0 mg KOH/g DGF C-V 3 HLB Value approx. 9 - - Natural Origin Index 1.0 - ISO 16128

Regulatory & Compliance

- Certifications & Compliance