Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Chemical Name

- Composite Materials Functions

- CAS No.

- 21645-51-2

- EC No.

- 244-492-7

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

Applications & Uses

- Markets

- Applications

- Composites Processing Methods

Properties

- Chemical Properties

Value Units Test Method / Conditions Al(OH)₃ 99.6 % - Fe₂O₃ 0.007 % - Loss on Ignition at 1000°C 34.6 % - Na₂O (Soluble) 0.04 % - Na₂O (Total) 0.3 % - SiO₂ 0.005 % - - Typical Properties

Value Units Test Method / Conditions Bulk Density (Loose) 0.45 g/cm³ - Bulk Density (Packed) 0.8 g/cm³ - Free Moisture at 105°C 0.25 % - Specific Gravity 2.42 - - Surface Area 3.0 m²/gm - TAPPI Brightness 95.0 - - - Particle Size Distribution

Value Units Test Method / Conditions Median Particle Diameter 5.0 μm - Screen Analysis on 325 mesh 0.01 % - Screen Analysis through 325 mesh 99.99 % -

Technical Details & Test Data

- Performance

Why is Huber’s MoldX® P18 Optimized ATH an Outstanding Choice for Pultrusion?

Versatility

The product can be used in all types of pultrusion applications and has the following advantages:

- Lower pull force at 50-75 weight % of fiberglass.

- 25 to 200 phr ATH loading depending on weight % of fiberglass and resin type.

- Either unsaturated polyester or acrylic resins or blends.

- Even at high loadings, compounds have very low pull force.

- Higher loadings with the same or faster line speeds and lower total compound cost.

- Maintains mechanical properties.

Consistency in Manufacturing

- Greatly reduced possibility of die lock-up.

- Reduced sedimentation resulting in less down time for resin bath clean-out.

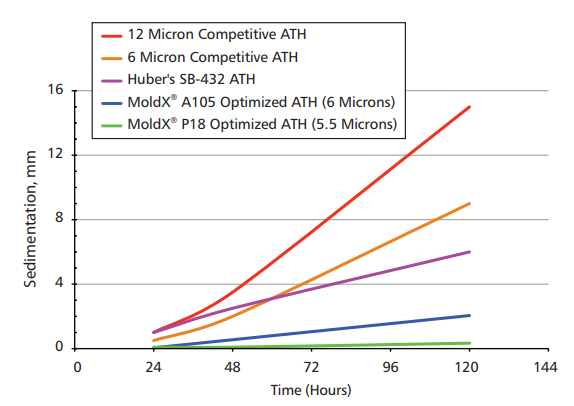

ATH Settling Behavior in Modar® Fire-Retardant Resin 875 at 25°C

Settling resistance is desirable for pultrusion to allow longer operating times between clean outs.