Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Chemical Name

- Composite Materials Functions

- CAS No.

- 21645-51-2

- EC No.

- 244-492-7

- Technologies

- Product Families

Features & Benefits

- Materials Features

Applications & Uses

- Markets

- Applications

- Composites Processing Methods

Properties

- Flame Rating

- Chemical Properties

Value Units Test Method / Conditions Al(OH)₃ 99.6 % - Fe₂O₃ 0.007 % - Loss on Ignition at 1000°C 34.6 % - Na₂O (Soluble) 0.025 % - Na₂O (Total) 0.2 % - SiO₂ 0.005 % - - Typical Properties

Value Units Test Method / Conditions Bulk Density (Loose) 0.85 g/cm³ - Bulk Density (Packed) 1.35 g/cm³ - Free Moisture at 105°C 0.2 % - Specific Gravity 2.42 - - Surface Area 1.4 m²/gm - - Particle Size Distribution

Value Units Test Method / Conditions Median Particle Diameter 10.0 μm - Screen Analysis < 10 micron 50.0 % - Screen Analysis through 325 mesh 80.0 % -

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Performance

For SMC, BMC, Hand Lay-Up, Epoxy and Polyurethane Applications:

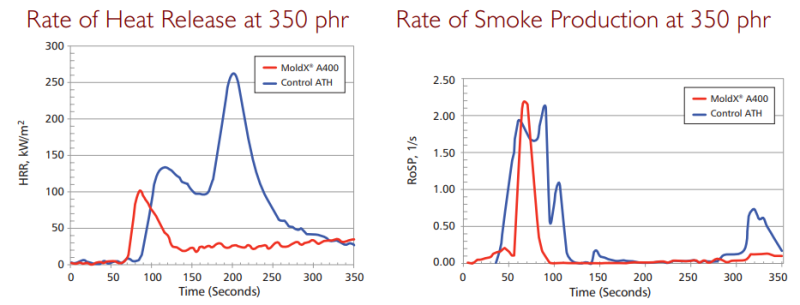

MoldX A400 is Huber’s highest performing optimized ATH grade. It is engineered to impart outstanding fire retardance and smoke suppression in fiberglass reinforced SMC without halogen additives. Formulations have better mechanical properties because less MoldX A400 is needed to pass the same flame retardant certifications that would be required of competitive ATH grades.

Above is the rate of heat release and of smoke production for cured composite panels made via the sheet molding process with the ATH loading level at 350 phr. The panels were 0.100 inches thick. MoldX® A400 optimized ATH easily outperforms competitive ATH products in the critical areas of flammability and smoke suppression.