Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Polymer Name

- Composite Materials Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Benefits

- Ability to machine tool surface without distortion permitting the manufacture of tools with complex shapes and tight tolerances

- Lighter weight compared to metal tooling allowing easier handling and reduced infrastructure investment

- Faster heat-up and cool-down rates relative to metal tools facilitating reduced production costs

- Reparability and potential for modification of tool dimensions following engineering changes

- Formulated to withstand several hundred autoclave cycles at 180°C (356°F)

- Coefficient of thermal expansion to match carbon/epoxy

- Vacuum integrity following machining

- Rapid material deposition as HexTool® is much thicker than standard composite tooling prepregs

Applications & Uses

- Markets

- Applications

- Composites Processing Methods

Properties

- Physical Form

- Mechanical Properties

Value Units Test Method / Conditions Tensile Strength at 23°C (73°F) (Dry) 260 (37.7) MPa (ksi) ASTMD3039 Tensile Strength at 180°C (356°F) (Dry) 210 (30.5) MPa (ksi) ASTMD3039 Tensile Modulus at 23°C (73°F) (Dry) 41 (5.95) GPa (msi) ASTMD3039 Tensile Modulus at 180°C (356°F) (Dry) 40 (5.80) GPa (msi) ASTMD3039 Compression Strength at 23°C (73°F) (Dry) 300 (43.5) MPa (ksi) ASTMD6484 Compression Strength at 180°C (356°F) (Dry) 270 (39.1) MPa (ksi) ASTMD6484 Compression Modulus at 23°C (73°F) (Dry) 32 (4.64) GPa (msi) ASTMD6484 Compression Modulus at 180°C (356°F) (Dry) 30 (4.35) GPa (msi) ASTMD6484 Flexural Strength at 23°C (73°F) (Dry) 380 (55.1) MPa (ksi) ASTMD790 Flexural Modulus at 23°C (73°F) (Dry) 38 (5.51) GPa (msi) ASTMD790 Short Beam Shear Strength at 23°C (73°F) (Dry) 50 (7.3) MPa (ksi) EN2563 Short Beam Shear Strength at 180°C (356°F) (Dry) 43 (6.2) MPa (ksi) EN2563 - Cured Properties

Value Units Test Method / Conditions NCured Ply Thickness: HexTool® M61 (2000) 1.27 (0.05) mm - NCured Ply Thickness: HexTool® M61 (4000) 2.54 (0.10) mm (in.) - Tg Postcured 275 (527) °C (°F) - Maximum Use Temperature 218 (425) °C (°F) - Coefficient of Linear Thermal Expansion (4.0 x 10^-6) °C - Minimum Initial Cure Temperature 190 (375) °C - - Uncured Properties

Value Units Test Method / Conditions Nominal Resin Content 38 % - Nominal Bundle Size (Prepreg Strip Size) 8.0 x 50 (0.315 x 1.97) mm (in.) - Nominal HexTool® Ply Areal Weight 2000 g/m2 - Specific gravity 1.55 - - Autoclave Work life at 21°C (70°F) 20 days - - Storage Life 12 months - -

Technical Details & Test Data

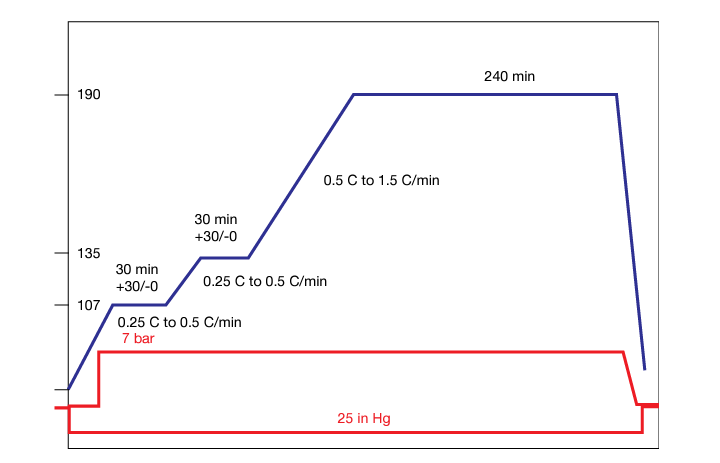

- Typical Autoclave Cure Cycle

Specific cure cycles [temperature, pressure (amount and application of)] depend on autoclave type and dimensions, the extent and type of tooling used and the size and complexity of the lay-up. Please contact your local Hexcel Technical Support for consultation prior to cycle definition. The following cycles are typical for HexTool® M61.

Cure Cycle

Low Temp Cure Cycle and Post Cure

- Part must be fully thermocoupled prior to the start of the cure cycle (ref. HexTool User Guide); deviations from recommended thermocoupling procedure or from recommended cure cycle may result in unacceptable part quality.

- Establish 25 in. Hg vacuum on part for minimum of 60 minutes.

- Heat part at 0.25-0.5ºC/min to 107 ºC (0.5-1.0ºF/min to 225ºF).

- When leading TC reaches 49ºC +/- 2.5ºC introduce 7 barr pressure at max of 0.65 barr/minute (120ºF +/5ºF introduce 100 psi pressure at a max of 10 psi/min).

- When lagging TC reaches 107ºC +/- 2.5ºC begin 30 minute soak (225ºF +/-5ºF begin 30 minute +30/-0 min soak).

- Heat part at 0.25-0.5ºC /min to 135ºC (0.5-1.0ºF/min to 275ºF).

- When lagging TC reaches 135ºC +/-2.5ºC begin 30 minute +30/-0 min soak (275ºF +/-5ºF begin 30 min. +30/-0 minsoak).

- Heat part at 0.5-1.5ºC/min to 190ºC (1-3ºF/min to 375ºF).

- When lagging TC reaches 190ºC +/-2.5ºC begin 240 minute soak (375ºF +/-5ºF begin 240 min. +15/-0 minute soak).

- Cool part at maximum rate of 2.5ºC/min to 66ºC (5ºF/min. to 150ºF) before releasing pressure.

Free Standing Post Cure Cycle

- Heat up to 150°C (300°F) at 0.5°-2°C/min (1°-4°F/min)

- Heat up to 220°C (425°F) at 0.25°-1°C/min (0.5°-2°F/min)

- Hold at 220°C (425°F) for 16 hours

- Cool down at 0.5°C/min (1°F/min) to 150°C (300°F)

- Cool down at 1°C/min (2°F/min) to 60°C (140°F)

Storage & Handling

- Product Handling and Storage

Store the product in its original (or equivalent) sealed packaging at -18°C (0°F). Prevent condensation on the productby warming to room temperature before opening vapor barrier bag (reseal for subsequent storage). The usual precautions when handling uncured synthetic resins and fine fibrous materials should be observed, see Material Safety Data Sheet. The use of clean disposable impervious gloves provides protection for the operator and avoids contamination of material and components.