Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Polymer Name

- Composite Materials Functions

- Technologies

- Product Families

Features & Benefits

- Advantages

- Before mixing:

- Longer out life storage of Part A & Part B: 12 months at room temperature (23 ± 3°C)

- Easier transportation regulations: aircraft shipment is allowed

* Dry: 23±5°C / 50 ± 7% RH

* Wet: 14 days in water at 70°C

Applications & Uses

- Markets

- Applications

- Composites Processing Methods

Properties

- Testing Conditions

Uncured resin data for Part A & Part

Isothermal Viscosities: EN6043

Gap: 0.5mm

Shear rate: 10 rad/s Strain: 4%

Rheology Profile: EN6043

Gap: 0.5mm Shear rate: 10 rad/s

Strain: 4%

Temperature range: from 30°C to 250°C

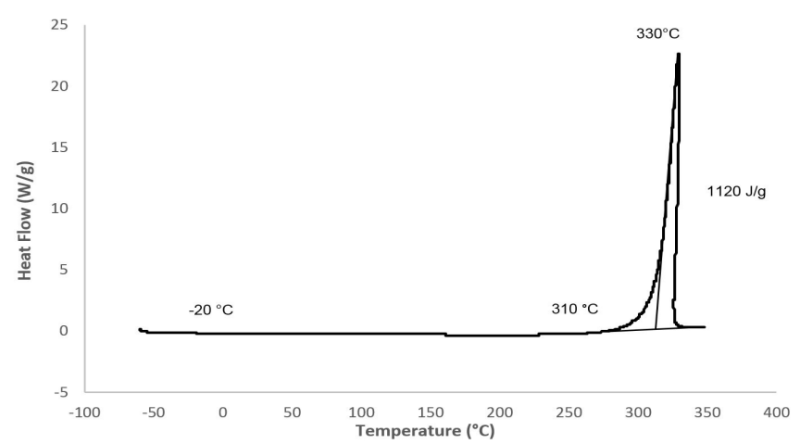

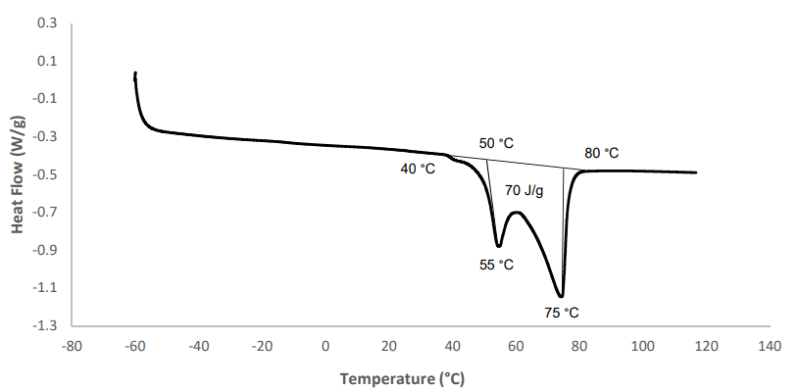

Standard DSC: EN6041

Heating rate: 10°C/min

Temperature range: from -60°C to 350°C

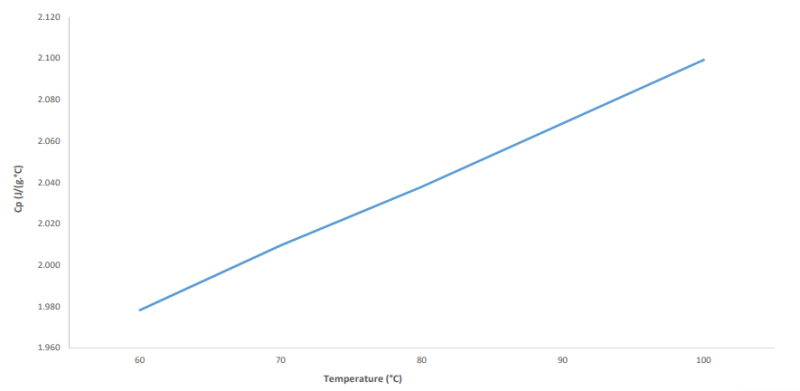

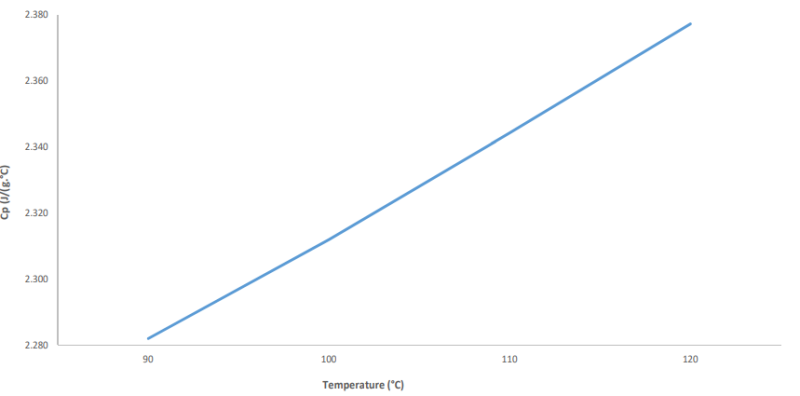

Modulated DSC

2 heating cycles: from -10°C to 110°C then from-50°C to 280°C at 2°C/min, Cp measured on second heating rate Oscillation: +/-1°C Period: 120s

Technical Details & Test Data

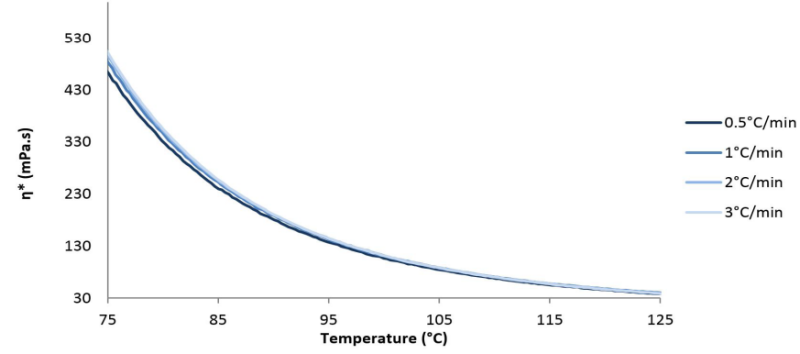

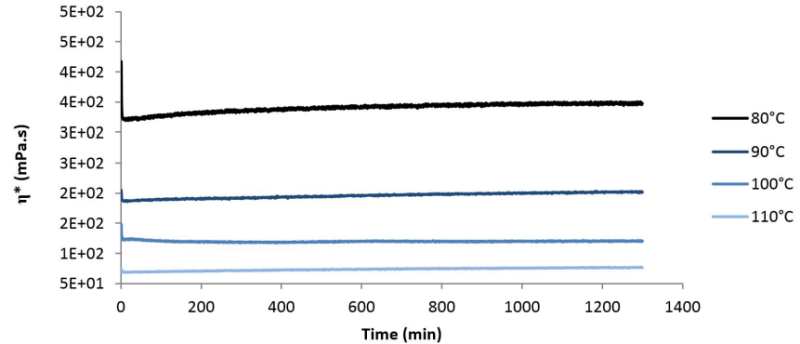

- Viscosity Profile

Part A

Figure 1: Rheology profile of HexFlow® RTM6-2 Part A

Figure 2: Isothermal viscosities of HexFlow® RTM6-2 Part A

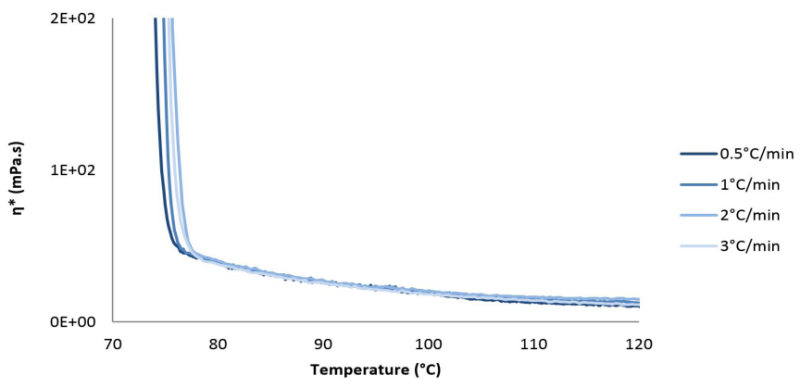

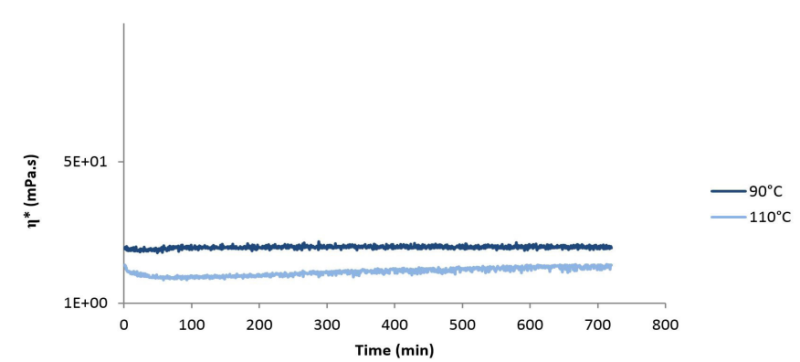

Part B

Figure 3: Rheology profile of HexFlow® RTM6-2 Part (Part B is solid at temperatures <80°C)

Figure 4: Isothermal viscosities of HexFlow® RTM6-2 Part B

- Heat Flow

Part A

Standard DSC parameters

Tg midpoint (°C) Enthalpy (J/g) T peak (°C) T onset (°C) -20 1120 330 310  Figure 5: Standard DSC HexFlow® RTM6-2 Part A

Figure 5: Standard DSC HexFlow® RTM6-2 Part A Figure 6: Specific heat of HexFlow® RTM6-2 Part A

Figure 6: Specific heat of HexFlow® RTM6-2 Part APart B

Standard DSC parameters

Enthalpy (J/g) T peak 1 (°C) T peak 2 (°C) Softening Tg (°C) Melting start T (°C) Melting end T (°C)

70 55 75 40 50 80  Figure 7: Standard DSC HexFlow® RTM6-2 Part B

Figure 7: Standard DSC HexFlow® RTM6-2 Part B

Figure 8: Specific heat of HexFlow® RTM6-2 Part B

Storage & Handling

- Shelf Life

- 12 months (20 - 26°C)

- Transport And Storage Of Uncured Resin

Shelf life before mixing (Part A & Part B): 12 months at room temperature (23 ± 3°C)