Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Polymer Name

- Composite Materials Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Advantages

- Monocomponent system

- Already degassed

- Easy to process

- High toughness

- Low moisture absorption

- Good solvent resistance

Applications & Uses

- Markets

- Applications

- Composites Processing Methods

Properties

- Typical Properties

Value Units Test Method / Conditions Pot Temperature 80 °C - Injection Temperature 150 °C - Viscosity at Injection Temperature 45 mPa.s - Cure Temperature 190 °C - Cure Time 2 hr - Viscosity at Pot Temperature max. 500 mPa.s - - Processing Parameters

Value Units Test Method / Conditions Cure Temperature 190 °C - Cure Time 2 hours - - Injection Temperature 150 °C - Pot Temperature 80 °C - Viscosity at Injection Temperature 45 mPa-s - Viscosity at Pot Temperature max. 500 mPa-s - - Neat Resin Properties

Value Units Test Method / Conditions G1C 1000 J/m2 - K1C (-m½) 1.88 MPa - Tg (Dry) 159 °C - Tg (Wet) 136 °C - Cured Density 1.2 g/cc - Tensile Strength 89.6 MPa - Tensile Modulus 3.3 GPa - Tensile elongation 3.6 % - Flex Strength 3-point 123 MPa - Flexural Modulus 100-4000 3 GPa - MEK Uptake, 6 Days Immersion 0.01 % - - Laminate properties

Value Units Test Method / Conditions CAI (30 J impact, RTA/Dry) 280 MPa - G1c (RTA/Dry) 947 J/m2 - ILS Strength (120°C/Wet) 36.6 MPa - ILS Strength (70°C/Wet) 48.1 MPa - ILS Strength (RTA/Dry) 71.6 MPa - IPS Modulus (70°C/wet) 3.1 GPa - IPS Modulus (RTA/dry) 4.2 GPa - IPS Strength (70°C/wet) 83 MPa - IPS Strength (RTA/dry) 104 MPa - OHC Strength (70°C/wet) 210 MPa - OHC Strength (RTA/dry) 273 MPa - - Properties on Composite Laminate

Sample

Injectex® G0926 SB: 5HS satin weave of 370 gsm with HexTow® AS4C 6K high strength fiber.

Fiber volume = 58%

Injection pressure = 3 bar + vacuum in mold

Cure cycle = 2 hours at 190°CLaminate Properties Condition HexFlow® RTM230 ST

OHC Strength (MPa) RTA/dry 273 70°C/wet 210 IPS Strength (MPa) RTA/dry 104 70°C/wet 83 IPS Modulus (GPa) RTA/dry 4.2 70°C/wet 3.1 CAI (30 J impact) (MPa) RTA/dry 280 G1c (J/m2) RTA/dry 947 ILS Strength (MPa) RTA/dry 71.6 120°C/dry 36.6 70°C/wet 48.1

Technical Details & Test Data

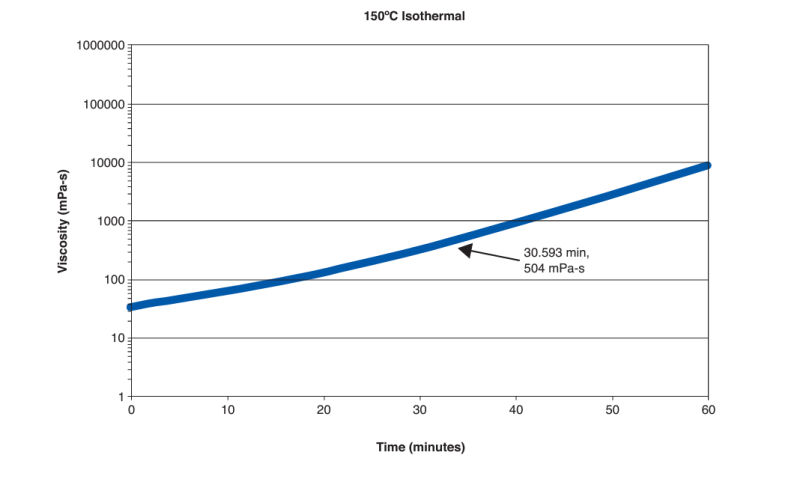

- Viscosity Profile

Packaging & Availability

- Availability

HexFlow® RTM230 ST is available with a wide range of HexForce® reinforcements.

Storage & Handling

- Shelf life

- 30 days (24°C)

- Shelf Life

- 18 months (-18°C)