Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Chemical Name

- Fluids & Lubricants Functions

- CAS No.

- 10043-11-5

- EC No.

- 233-136-6

- Technologies

- Product Families

Features & Benefits

- Fluids & Lubricants Features

- Advantages

► Reduces the friction and wear of engine and gearbox

► Increases the service life and smooth operation of engines, gearboxes and other equipment

► Higher efficiencies achieved through reduced energy consumption

► Easy mixed with the vast majority of oils and oil-soluble lubricants

► Finely dispersed Boron Nitrid particles minimize risk of filter blockage- Benefits

High Performance: The increase in load capability is directly attributable to the solid lubricant content. The dry lubricant film and its lubricity remain constant even under high loads. Surface roughness peaks remain protected. HeBoLub® exhibits good creep and wetting properties.

Economy: Fuel and energy consumption are reduced as a result of a reduction in friction. This has a very positive impact on efficiency and economy.

The use of HeBoLub® increases the Long-Life-Cycle of components due to the critical wear resistance layer that is formed on the mating surfaces.Productivity

HeBoLub® is easy to use and easily dispersed. It offers high compatibility and optimizes the productivity of production processes.Safe in use

HeBoLub® is physiologically inert and compatible with seals and other rubber based components. The effectiveness of the Boron Nitride particles is retained even under extreme conditions as well as at high service temperatures.- Properties

► Excellent lubricating and sliding action resulting from the finely dispersed Boron Nitride powder

► Excellent lubrication at low as well as high temperatures

► Low creep and good surface wetting properties

► High stability, no separation of the oil base over time

► High contact pressure resistance

Applications & Uses

- Markets

- Applications

- Fluids & Lubricants Type

- Fluids & Lubricants End Use

- Applications

HeBoLub® for various applications and industries

- Power plant

- Chain drives and conveyors

- Metal processing and forming

- High performance power transmissions

- Typical Areas of Application

► Lubricant additive for engines, gearboxes, pumps and compressors

► Lubricant additive for chain drives and conveyors

► Lubricant additive for metal forming processes, grinding, stamping and wire/tube drawing processes

► Not suitable for: Automatic gearboxes and fluid couplings- Recommendations for Processing

► We recommend that the user ensures that the dispersion is well mixed by stirring prior to adding to the lubricant

► Heating the dispersion to around. 50 – 60°C reduces the viscosity of the oil base to facilitate better mixing

Properties

- Physical Form

- Typical Properties

Value Units Test Method / Conditions Solid content (BN) (highly dispersive) 30 % - Density (at 25°C) approx. 1.06 g/cm³ Flash Point 220 °C

Technical Details & Test Data

- HeBoLub® for Tribological Solutions

HeBoLub® - for improved lubricating properties, higher thermal conductivity, higher load capability

Our HeBoLub® product innovation is a high performance lubricant additive for the widest range of applications.

HeBoLub® finds application in high performance power transmission systems, power plant, as well as in the metal processing and metal forming industries.

The new Boron Nitride dispersion in oil comprises a mineral base oil combined with fine, crystalline hexagonal Boron Nitride particles. Even small quantities of HeBoLub® improve the performance of lubricants and as a result contribute to reducing wear.

The incorporation of Boron Nitride, a solid lubricant, in HeBoLub® sets new standards in performance, productivity and economy.

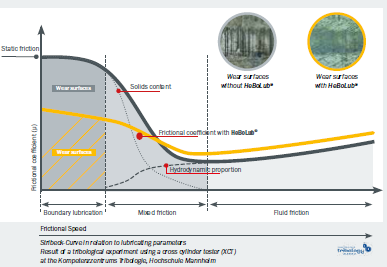

The effectiveness of HeBoLub® is particularly evident in highly demanding boundary lubrication conditions, especially when high temperatures, high loads and low frictional speeds are in evidence.HeBoLub® reduces wear

Without HeBoLub®

Wear increases as no effective lubricating film is formed on the surface roughness peaks on the mating surfaces.

With HeBoLub®

HeBoLub® - forms a separating protective layer to help prevent wear. This protective layer is particularly effective in boundary lubrication conditions under high loads or low frictional speeds

HeBoLub® effectively stabilizes frictional effects over the full spectrum. Extremes are

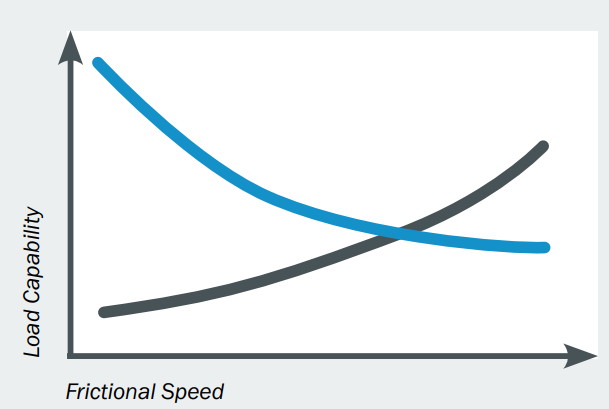

smoothed out and wear is reduced as a result of consistent lubrication.- HeBoLub® significantly increases the Load Capability

The increase in load capability ensures a constant lubricant film even in critical conditions, specifically at low frictional speeds.

- HeBoLub® smoothes in Long Service Life Conditions

- Small Boron Nitride particles settle in the scored mating surfaces to smooth the surface. This reduces the coefficient of friction, thus reducing wear, resulting in smoother running.

- This repair effect is particularly noticeable with rough surfaces in demanding applications.

- The effectiveness of the repair ultimatelydepends on the Boron Nitride particle size as well as the surface roughness

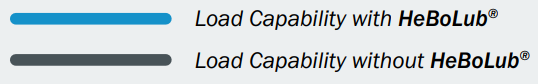

- HeBoLub® increases Thermal Conductivity

HeBoLub® contains finely dispersed Boron Nitride particles which build heat dispersion paths to improve the thermal conductivity of the lubricant.

Measured results of the thermal conductivity of HeBoLub® by “flucon fluid control GmbH“

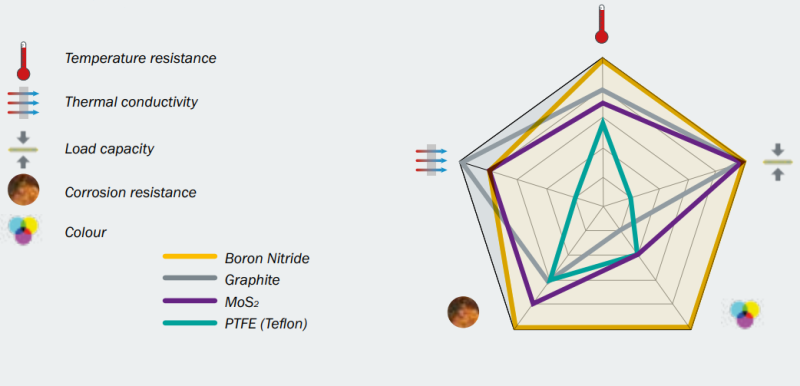

- Solid Lubricants in Comparison

- HeBoLub® improves the Temperature Resistance

Boron Nitride exhibits a particularly high temperature resistance. It is stable up to 900°C under Oxygen and to temperatures in excess of 2,000°C in inert conditions or under vacuum – setting new performance standards in comparison with other solid lubricants such as PTFE (Teflon), MoS2 or Boron Nitride Graphite.