Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Carrier

- Chemical Name

- Industrial Additives Functions

- EC No.

- 684-848-2

- CAS No.

- 69011-17-2

- Technologies

- Product Families

Applications & Uses

- Markets

- Applications

- Applicable Processes

- Operation Tips

Operate Solution Flow Rate(BV/h) Dosage(BV) Sugar Recovery Clean Water 2.0-4.0 2.0-3.0 Back Wash Clean Water 2.0-4.0 2.5-3.0 Regenerate 4~5%NaOH

Solution1.5-2.0 2.0-3.0 Replacement DI Water or Pure

Water1.0-2.0 1.5~2.0 Rinse DI Water or Pure

Water10~15 4.0~6.0 Flushing DI Water 10~15 4.0~6.0 Operating Sugar Liquor 2.0~4.0 30~60 - Reference Parameters in Application

Item Reference Value Height of Resin Bed, m 1.5-3.0 Back Wash Space, % 80.0-100.0 Regenerant Agent NaOH Regenerant Density, % 4-5 Regenerant Dosage, m3/m3 -R 1.8-2.2 Regenerate Contact Time, min 50-70 Replacement Time, min 30-50 Rinse Flow Rate, m/h 10-15 Operation Temperature, °C 80 Max Temperature Limited, °C 30-60 pH 0-7

Properties

- Physical Form

- Appearance

- Milk white to straw yellow opaque beads

- Typical Properties

Value Units Test Method / Conditions Matrix Styrene-DVB - - Functional Group Tertiary Amino Groups - - Ionic Form Free Base - - Moisture Content 48 - 58 % - Capacity Based on Weight min. 4.80 mmol/g - Capacity Based on Volume min. 1.45 mmol/ml - Shipping Weight 1.03 - 1.06 g/ml - True Density (Wet) 0.65 - 0.75 g/ml - Particle Size Range (0.45~1.25mm) min. 95.0 % - Low Limited (<0.45mm) max. 1.0 % - Uniform Coefficient max. 1.60 - - Whole Beads min. 90.0 % -

Technical Details & Test Data

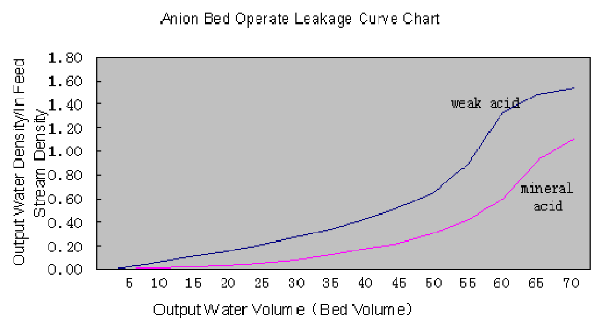

- Bed Operate Leakage Curve Chart

Packaging & Availability

Storage & Handling

- Storage Conditions

The product should be stored in dry and volatile premises.