Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Base Chemicals Functions

- CASE Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- CASE Ingredients Features

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Base Chemicals End Uses

- Application

Applied in polyurethane based products such as synthetic leather, artificial leather, coatings resin, paint, adhesive, elastomer and thermoplastic resin.

Properties

- Physical Form

- Appearance

- Pale Yellow Transparent Liquid

- Typical Properties

Value Units Test Method / Conditions Hydroxyl Value 112 ± 4 KOHmg/g - Viscosity at 75°C 350 ± 50 mm2/s - Water Content max. 0.05 % - Specific Gravity at 75°C 1.08 - - Flexibility of PCD/1,4-BG/MDI formulation Flexible Stiff - - - Set Properties

Value Units Test Method / Conditions Permanent Set 9.6 % - Hysteresis Loss 54.8 % -

Technical Details & Test Data

- Flexibility

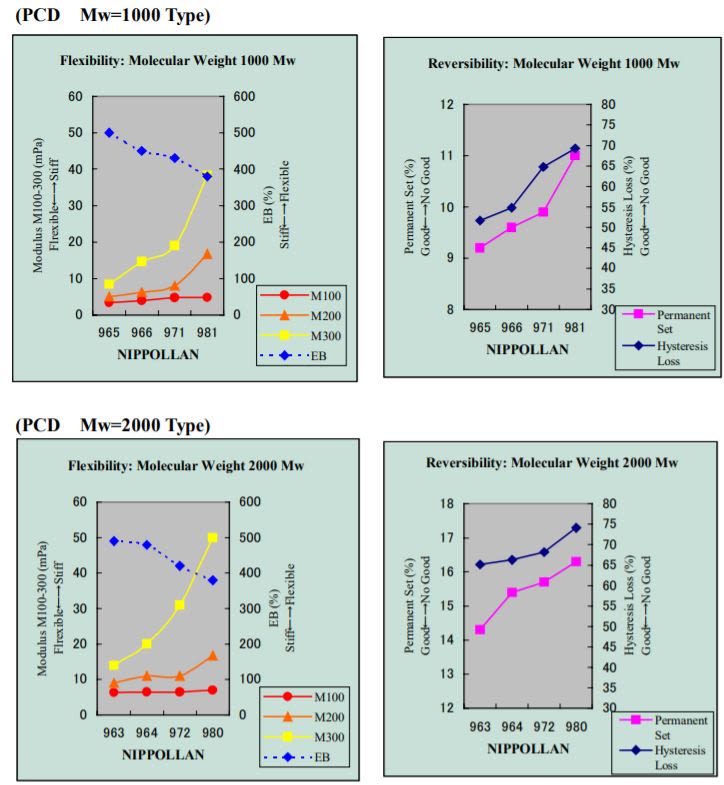

The following graphs show the improved flexibility of the new NIPPOLLANs by testing of modulus (M100-M300), elongation at break (EB) and reversibility properties using the formulation PCD/1.4BG/MDI (hard segment content approx. 32%).

Comparison of flexibility and reversibility.

- Resistance

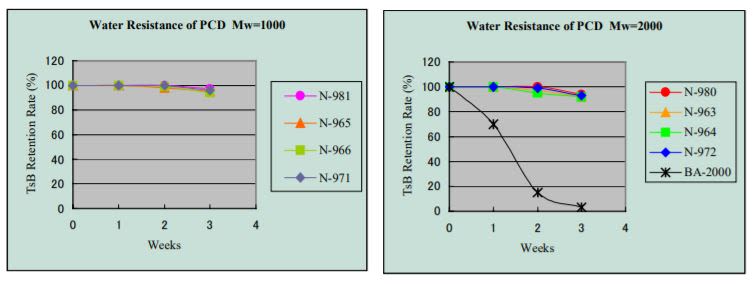

Water Resistance

Test Method

- Test film: Aprox. 100μm thickness

- Test Condition: 80°C hot water

- Test Standards: JIS K7311

- BA-2000: (BG/AA-2000)/BG/MDI (Approx. 32% hard segment)

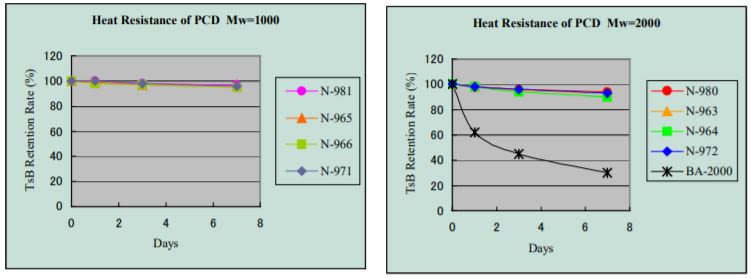

Heat Resistance

Test Method

- Test film: Aprox. 100μm thickness

- Test Condition: 150°C in Gear Oven

- Test Standards: JIS K7311

- BA-2000: (BG/AA-2000)/BG/MDI (hard segment content approx. 32%)

Safety & Health

- handling Precautions

- Although the polycarbonate ester introduced here are generally considered stable chemicals, exposures to moisture followed by reaction with isocyanate may cause trouble. Therefore, it is advisable to store the product in airtight containers away from direct sunlight and kept below room temperature. In addition, avoid usage of product in humid places and ensure that equipment and tools used are dry.

- Once opened, the container should be purged with nitrogen and resealed for future usage.

Packaging & Availability

- Packaging

- 200L drum NET 215kg

- 18L tin can NET 18kg

Storage & Handling

- Shelf Life

The shelf life, when stored in an airtight state and maintained at room temperature is 6 months after production.