Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Carrier

- INCI Name

- Cosmetic Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- Benefit Claims

- Labeling Claims

- Elastomer Gel Key Benefits

- Allows the addition of elastomers and powders into difficult formulating settings

- Minimal or no additional emulsifier requirement; reduces possible irritation profile

- Provides enhanced esthetics to formulations; unique formula break upon application

- Cold process compatible for energy/cost savings; can be mixed directly with aqueous phase at suggested levels with minimal or no

additional emulsifier - Delivers excellent non-tacky, non-oily, smooth characteristics

- Elastomer network offers sebum absorption and control

- Transformation into matte appearance with powdery after feel

Applications & Uses

- Markets

- Applications

- Application Format

- Color Cosmetic Applications

- Skin Care Applications

- Sun Care Applications

- Treatment Product Applications

- Formulation Guidelines

- Designed to be formulated directly with aqueous phase

- Easily formulated in water systems at 60°C or below

- Can be added to all existing emulsions types for improved skin fee

Properties

- Physical Form

- Appearance

- Translucent gel

- Physical Properties

Value Units Test Method / Conditions Microbial Content max. 100 CFU/g - Non-Volatile Matter (165°C, 1.5g, 3hrs, Air Convection Oven) 19.00 - 23.00 wt% AP-38 Grant Industries, Inc. pH 5.50 - 7.50 Preservative Diocide 0.1 % - Viscosity at Amorphous State (at 25°C Brookfield DV-I+, Spindle TE, 0.3rpm, 1.0min measured right after mixing) 700,000 - 1,000,000 cPs

Technical Details & Test Data

- Gransil SIW Technology

- The simple (and effective) way to load silicone elastomers into water-based formulations; water-coated GRANSIL SiW ELASTOMER GELS are the new vehicle of choice for creating personal care products. Technically GRANSIL SiW ELASTOMER GELS offer formulators the ideal opportunity for loading high levels of Polysilicone-11 elastomer into water-based gel structures with minimal use of emulsifiers (at levels below 0.5%), and by cold processing methods. Stable formulations achieved with such low levels of emulsifiers also serve as excellent delivery-bases for active ingredients.

- The challenges of dispersing standard silicone elastomers in water are well known. Standard silicone elastomers can be very difficult to disperse uniformly in external water phase emulsions or aqueous gels due to their inability to fit into o/w micelles, and general hydrophobic incompatibility with water. Often when processing, excessive levels of surfactants and high shear energy is required to disperse and maintain particles to a stable state. High concentrations of surfactants (which coat particles to maintain a dispersion) unfortunately reduce the elastomer sensory properties by creating tackiness. Surfactants are also more likely to cause skin irritation or some level of barrier disruption. The unique design of versatile GRANSIL SiW ELASTOMER GELS resolves these challenges.

- GRANSIL SiW ELASTOMER GELS can be formulated to offer unique sensory benefits with a water-topowder break on application. The outer water phase cools, soothes and hydrates skin on contact, while seconds later silicone elastomer particles release from a gel matrix to fill lines and even complexion with a soft powder-like texture. GRANSIL SiW ELASTOMER GELS can also be used to improve sensory esthetics of existing emulsions with easy post-addition. Grant Industries offers a wide range of gels from high volatility to non-volatile meeting the sensory and regulatory requirements of any formulation project. Applications include skin care, daily wear, color cosmetics, sun care, body care, and hair care.

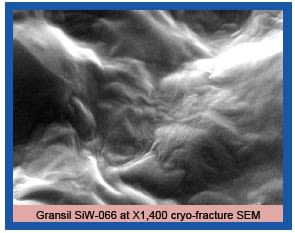

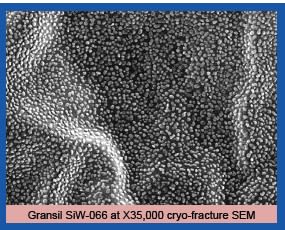

Image below demonstrates the unique design of Gransil SiW systems where Polysilicone-11 particles are immersed in water.

Typical Gransil SiW elastomer gels hold roughly 10% water on the outer phase and 90% Polysilicone-11 elastomer gel in the inner phase.