Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Reinforcement Form

- Reinforcement Material

- Composite Materials Functions

- Technologies

- Product Families

Applications & Uses

- Markets

- Applications

- Composites Processing Methods

- Usage

A reinforcement yarn for composites, plastics and rubber.

Used by Textile Companies to produce:

- Woven Fabrics

- Multi-axial Fabrics

- Braids

- Substrate for prepreg

As a Continuous yarn:

- Pultrusion

- Filament Winding

- Substrate yarn for nickel coating

- D-LFT

- Yarn for precision cutting into chopped strands

- Precursor for bio-based carbon fiber

- Raw material for producing bio-nano-fiber

As a Functional yarn:

- For use in commercial greenhouses as a bio-based trellis yarn

Properties

Technical Details & Test Data

- How Is Biomid Fibre Made?

The origin of the raw materials to produce BioMid Fiber are sustainably grown Western Canadian Trees

Over 93% of harvested trees goes into lumber production. BioMid is made from the 7% of the tree that is considered waste. Electing to use trees as the cellulose source eliminates the need for displacing food crop lands and does not require special irrigation, pesticides or fertilizer.

Production

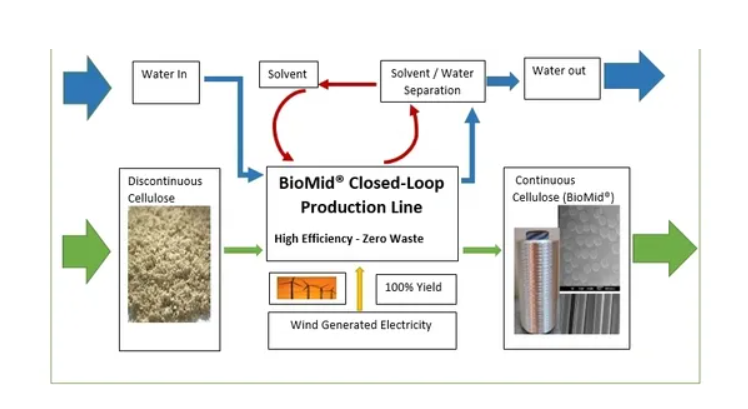

BioMid Fiber does not utilize the viscose process, rather, it's produced on a zero-waste, closed-loop production line that has only water, cellulose and electricity as inputs.

BioMid is a joint development of Gordon Shank Consulting and ENC Korea.

Packaging & Availability

- Availablity

BioMid is supplied in 1, 3 or 5 kg. bobbins.