Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Fillers Included

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Special Features

- Available in all colors

- UV stabilized available

- Available with mold release aid

- Also available as a particularly easy-flowing type

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Areas of Application

Technical injection molded parts from a wide variety of industries (automotive, electrical, electronic, mechanical engineering, ...)

- Processing Information

Pretreatment / drying

Drying temperature in °C: 80 - 100

Drying time in h (Dry air dryer): 2 - 4- Max. water content during processing is 0.05%.

- For downtimes of 4 hours or more, we recommend lowering the temperature of the dryer by 40°C.

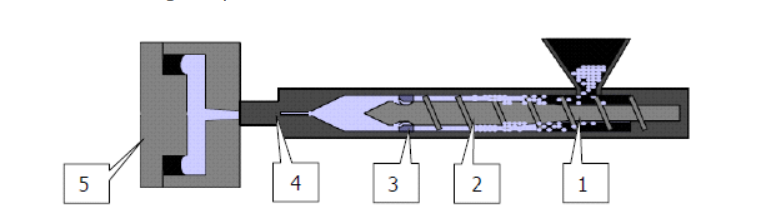

Processing temperature

Melt temperature: 250°C - 280°C

1st zone: 240°C - 260°C

2nd zone: 250°C - 270°C

3rd zone: 250°C - 280°C

4th zone: 250°C - 280°C

5th zone: 70°C - 100°C- Shrinkage behavior according to literature: 0.25 - 0.55 % (depending on the component geometry and the process control.

- The stated values are to be understood as guide values and can vary in particular depending on the color or filler content.

Test

Values unless expressly stated, the values given were determined on standardized test specimens at room temperature. The information is to be regarded as a guide, but not as a binding minimum. Please note that the properties can be significantly influenced by the tool design, the processing conditions and the coloring.Processing

Instructions under the recommended processing conditions, small amounts of decomposition products can be given off during processing. According to the safety data sheet, compliance with the specified occupational exposure limit values must be ensured through adequate extraction and ventilation in order not to impair the health and well-being of the machine operator. The prescribed processing temperatures must not be significantly exceeded in order to avoid severe partial decomposition of the polymer and elimination of volatile decomposition products.

Properties

- Mechanical Properties

Value Units Test Method / Conditions Charpy Impact Strength (23°C) 35 kJ/m² ISO 179 / IeU Charpy Impact Strength (23°C) 8 kJ/m² ISO 179 / IeA Charpy Impact Strength (-30°C) 35 kJ/m² ISO 179 / IeU Charpy Impact Strength (-30°C) 8 kJ/m² ISO 179 / IeA Tensile Modulus (1mm/min) 6400 MPa ISO 527-1 - Typical Properties

Value Units Test Method / Conditions Density (23°C) 1.29 g/cm³ ISO 1183 Density (23 °C) 1.29 g/cm³ ISO 1183 Shrinkage 0.25 - 0.55 % - - Thermal Properties

Value Units Test Method / Conditions Heat Resistance HDT A (1.80MPa) 119 °C ISO 75-2 Heat Resistance HDT B (0.45MPa) 129 °C ISO 75-2 Vicat Softening Temperature (50°C/50N) 130 °C ISO 306 - Rheological Properties

Value Units Test Method / Conditions MVR (260°C/5kg) 22 cm³/10min ISO 1133