Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

- Origin

The FiberVisions® NForz fiber is presently produced at the FiberVisions a/s plant in Denmark. NForz is a trademark of FiberVisions.

Features & Benefits

- Materials Features

- Product Highlights

PP Fibers of the Finest FiberVisions Quality FiberVisions has been active in the PP fiber market for more than three decades and has substantial know-how within PP fibers for a multitude of applications.

The fiber has the following features:

- High performance. The fiber’s strength level, spin finish type and content will be adjusted to each specific application. It also guarantees the customer a close cooperation with all parts of the FiberVisions competence functions. In addition, the fiber is supported by strong R&D experience.

- A high, uniform quality, supported by the concept of longspinning fiber manufacturing. Also, FiberVisions a/s has been ISO 9001 certified for more than 10 years.

- Our longspinning fibers have a broad temperature window, which makes a thermal stabilization of the needlefelt product very easy and convenient.

Why PP Fibers?

- FiberVisions® NForz fibers are made from polypropylene (PP), which has a number of remarkable characteristics:

- Polypropylene is the lightest of all fibers (0.91 g/cm³), and lighter products with same coverage as products made from other fibers can be made from PP fibers.

- It has the lowest moisture absorption of all fibers. Dirt will not penetrate the fiber and can easily be removed from the surface.

- PP fibers have the same tensile strength wet or dry, unlike other fibers.

- FiberVisions PP fibers are all highly resistant to both acids and alkalis and to most organic chemicals. The fiber does not rot and is not easily attacked by microorganisms or molds.

- Benefits

Superior fabric consistency, tailored attributes such as UV resistance, color, FR, etc.

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers End Uses

- Applications

Geosynthetics, Needlepunch Fabrics

Properties

- Color

- Typical Properties

Value Units Test Method / Conditions Dtex 1.7 - 10 Tensile Strength 2.0-5.0 cN/dtex Internal FV test Elongation 180 - 240 % Internal FV test Crimp Frequency Specified by customer - Internal FV test Shrinkage 2 - 10 % Internal FV test Spin Finish Level 0.3-0.4 % Internal FV test Fiber Length 40,50,60,80 mm Internal FV test

Technical Details & Test Data

- Efficiency

The NForz fiber is not a fiber with the standard spectrum of properties: needlepunching fibers with high fiber strength and low elongation. The FiberVisions® NForz is a fiber with medium to high fiber tenacity combined with higher-than-normal elongation. The process advantage for the customer is that the FiberVisions long spin fibers do not easily break during needling.

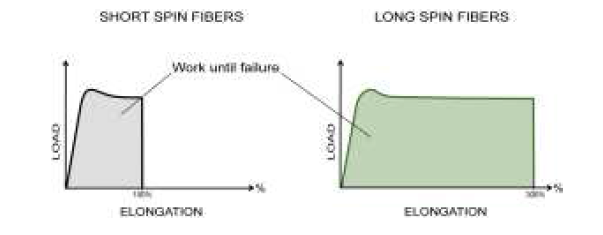

A high elongation fiber provides for increased toughness and the customer can achieve stronger nonwovens without sacrificing nonwovens elongation. The tenacity and elongation curves have the following shapes:

Other Info -

Polyolefin fibers consist of 99% carbon and hydrogen. The remaining 1% consist of water and applied spin finish. The fiber bales are protected with polyolefin foil and closed with polyester straps. The product and the packaging materials are suitable for recycling and combustion. Inhouse waste should be kept clean to facilitate direct recycling. In disposal of any waste, be certain all applicable regulations are met

Packaging & Availability

- Country Availability

- Regional Availability

- Additivation

FiberVisions® NForz fibers are available raw white, and spun-dyed gray and black. The spun-dyed colors ensure a uniform color throughout the entire fiber cross section, making the fiber exceptionally colourfast to light and wear. A standard color card is not available. Customer-specific colors can be made. FiberVisions fibers for technical textile applications are, if requested, specially treated with UVstabilizers during manufacturing to obtain resistance against the effect of UV in sunlight. Furthermore, the FiberVisions® fibers can possess additional heat stabilization, which extends the lifetime of the fibersin hightemperature applications. The