Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Features And Advantages

FiberVisionsâ HY-Comfort is a development which points towards new generations of products. Manufacturers of carded, thermal bonded coverstock will experience a fiber with features which ensure a distinctively better, competitive nonwoven product:

- Excellent softness

- Broad bonding window

- Easy to process

- Good liquid transport properties

- Excellent nonwoven properties

The quality of the fibers is secured by highly skilled and qualified operators, a strict ISO 9001 certified quality assurance system, and very advanced fiber production facilities.

Advantages for Roll Goods Manufacturers and Converters

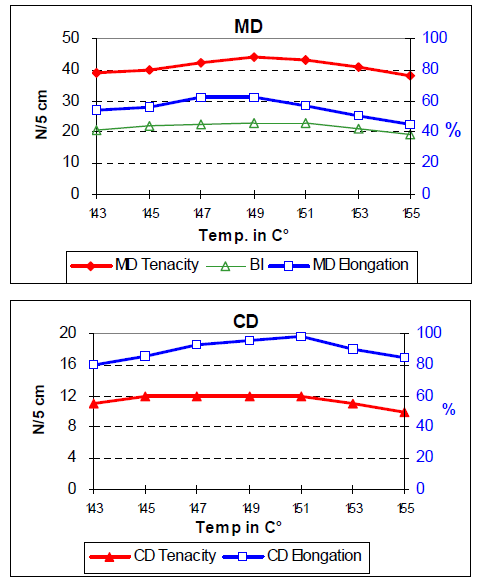

The manufacturers of nonwovens will experience benefits with respect to better processability due to a broad bonding window (up to 15-20°C) and high carding speed (up to 200 m/min.), while obtaining very good nonwoven tenacities. For converters the well-known soft texture of carded, thermal bonded nonwovens is even enhanced, thus increasing the comfort for the diaper user. Furthermore, HY-Comfort coverstocks have better uniformity, drapeability and bulkiness compared to spunbonded materials. Nonwovens made from FiberVisionsâ HY-Comfort can easily be laminated to other materials (e.g. films) due to the broad bonding window.

- Benefits

Softness, bonding strength, fluid management

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Applications

Topsheet, Carded Thermalbond Fabrics, Acquisition layer

Properties

- Physical Form

- Typical Properties

Value Units Test Method / Conditions Bursting Strength Of The Fiber 1.7 -2.1 cNidtex Internal FV test Elongation At Break 320 - 400 % Internal FV test Fiber Length (Under A Prescribed Load) 40, 50, 60 mm Internal FV test Raw Material (Pp) 100 % - Softening Point 140 - 150 °C - Melting Point 162 °C - Finish Level (Weight) 0.35 % Internal FV test Bonding Index (Combining MD And CD Tensiles) 18 - 24 N/5 cm Formula Tensile Strength (Md) 31 - 45 N/5 cm Internal FV test Tensile Strength (Cd) 10 - 15 N/5 cm Internal FV test Elongation (Md) 50 -100 % Internal FV test Elongation (Cd) 90 - 140 % Internal FV test Strike Through Time max. 3 sec Internal FV test Rewet max. 0.15 g - Crimp Frequency Internal (KD, No. of crimps/10 cm) Variable Internal FV test Weight of a Fiber (10 km/length) 1.3 - 4.4 dtex Internal FV test

Technical Details & Test Data

- Results from FiberVisions a/s Pilot Carding & Calendering Line

FiberVisions has obtained the following nonwovens data from tests on the carding & calendering line at a carding speed of 100 m/min. (Typical data for a 20 g/m² product - based on 2.2 dtex fibers):

Packaging & Availability

- Country Availability

- Regional Availability

- Availability

FiberVisionsâ HY-Comfort are available in dtex from 1.3 to 10 dtex. The fine fibers in 1.7 dtex can be used to improve the coverage of nonwovens, as the same grammage will increase the number of fibers per m² by approx. 30%, thereby improving the uniformity of the coverstock. Fine fibers also improve the softness and drapeability of the fabrics