Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Fillers Included

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Fuse Holder Application Data

Details

The fuse holder is a vital element in LVSG that protects different electrical loads against short circuit current. The application houses the fuse and facilitates easy assembly or replacement. Herein, the thermoplastic materials from Envalior offer an advantage over traditional materials.Benefits

- ForTii® allows the Fuse holder to withstand high temperatures and the material has a high impact resistance

- Productivity improvement

- Laser printing

- Snap fitting

- DIN rail mounting

- Speed Sensor Application Data

Details

Many different sensor types/systems: Hall-, ABS-, Oil-, MAF-, Air Bag-, Throttle- Sensor Crankshaft, Camshaft, ETC, Seat position.Benefits

- Stanyl® PA46, ForTii® PA4T, Akulon® PA66, Akulon® PA6, Arnite® PBT allow for reliable solutions due to high temperature resistance, high toughness levels and good electrical insulation properties

- Stanyl® PA46 allows for cost effective solutions due to a better flowability and processability than PPS and PPA enabling therefore thin wall designs

- ForTii® PA4T allows for reliable solutions exposed to very high peak temperatures due to its melting point of 325 C

- WtB and BtB Connectors Application Data

Details

Performance materials like our Stanyl® and ForTii® are helping manufacturers respond to trends for increased miniaturization (and therefore complexity) inside electronic devices – while also providing a more robust alternative to traditional materials like Liquid Crystal Polymer (LCP). Both Stanyl® and ForTii® are available in halogen and red phosphorous-free grades.Benefits

- Stanyl® PA46 and ForTii® PA4T allow for reliable solutions due to their high-heat resistance, a unique balance of high stiffness and good flowability and high strength and creep resistance levels leading to good pin retention

- Stanyl® PA46 and ForTii® PA4T allow for cost effective solutions to due good processability and high flowability enabling thin walled designs

- Automotive E-Motor Bobbins Application Data

Details

Stanyl® PA46 also used in connectors, e-motor parts, bobbins, sensors, fuse boxes. Thermoconductive Stanyl XL-T (P968A) in use as well; ForTii® PA4T and Xytron™ PPS also materials to be used in electromotor applicationsBenefits

- Stanyl® PA46 allows for reliable solutions due to a high temperature resistance (UL1446 class H certified) and creep resistance at elevated temperatures, high toughness levels and good electrical insulation properties

- Stanyl® PA46 allows for cost effective solutions due to a good flowability and processability enabling therefore thin wall designs

- Xytron™ PPS allows for super high temperatrue resistance for long term.

- Positition Sensor Application Data

Details

Many different sensor types/systems: Hall-, ABS-, Oil-, MAF-, Air Bag-, Throttle- Sensor Crankshaft, Camshaft, ETC, Seat position.Benefits

- Stanyl® PA46, ForTii® PA4T, Akulon® PA66, Akulon® PA6, Arnite® PBT allow for reliable solutions due to high temperature resistance, high toughness levels and good electrical insulation properties

- Stanyl® PA46 allows for cost effective solutions due to a better flowability and processability than PPS and PPA enabling therefore thin wall designs

- ForTii® PA4T allows for reliable solutions exposed to very high peak temperatures due to its melting point of 325 C

- Reflow Connectors Application Data

Details

PA46, PA4T excellent flow (> PEEK, PPA) PA4T low moisture absorptionBenefits

- Stanyl® PA46 and ForTii® PA4T allow for reliable solutions due to their high melting temperatures (allowing the use of high reflow temperatures) and high mechanical performance (implying a reduced reject rate during pin assembly + meeting mechanical specification also after reflow soldering)

- ForTii® PA4T increases the reliability even due to a high dimensional stability, a low and isotropic CLTE leading to high co-planarity and low warpage after soldering

- Stanyl® PA46 and ForTii® PA4T allow for cost effective solutions due to their ease of processability and flowability (enabling thin wall designs)

- Brushholders (Electro Motors) Application Data

Details

Stanyl® PA46 also used in connectors, e-motor parts, bobbins, sensors, fuse boxes. Thermoconductive Stanyl XL-T (P968A) in use as well; ForTii® PA4T and Xytron™ PPS also materials to be used in electromotor applicationsBenefits

- Stanyl® PA46 allows for reliable solutions due to a high temperature resistance (UL1446 class H certified) and creep resistance at elevated temperatures, high toughness levels and good electrical insulation properties

- Stanyl® PA46 allows for cost effective solutions due to a good flowability and processability enabling therefore thin wall designs

- Xytron™ PPS allows for super high temperatrue resistance for long term.

- EGR Sensor Application Data

Details

Sensor measures temperature of EGR (exhaust gas recirculation) and verifies function of EGR valve. Max temperature at tip of 300°C.Benefits

- ForTii® PA4T and Stanyl® PA46 allow for reliable solutions due to their high melting point of 325 and 295 °C resulting in no deformation at very high sensor tip temperatures and to their resistance to erosion from contamination in the exhaust stream

- ForTii® PA4T and Stanyl® PA4 allow for cost effective solutions versus PEEK, LCP or other PPA

- Endlaminates (Electro Motors) Application Data

Details

Stanyl® PA46 also used in connectors, e-motor parts, bobbins, sensors, fuse boxes. Thermoconductive Stanyl XL-T (P968A) in use as well; ForTii® PA4T and Xytron™ PPS also materials to be used in electromotor applicationsBenefits

- Stanyl® PA46 allows for reliable solutions due to a high temperature resistance (UL1446 class H certified) and creep resistance at elevated temperatures, high toughness levels and good electrical insulation properties

- Stanyl® PA46 allows for cost effective solutions due to a good flowability and processability enabling therefore thin wall designs

- Xytron™ PPS allows for super high temperatrue resistance for long term.

- Coil Insulation Application Data

Details

Stanyl® PA46 also used in connectors, e-motor parts, bobbins, sensors, fuse boxes. Thermoconductive Stanyl XL-T (P968A) in use as well; ForTii® PA4T and Xytron™ PPS also materials to be used in electromotor applicationsBenefits

- Stanyl® PA46 allows for reliable solutions due to a high temperature resistance (UL1446 class H certified) and creep resistance at elevated temperatures, high toughness levels and good electrical insulation properties

- Stanyl® PA46 allows for cost effective solutions due to a good flowability and processability enabling therefore thin wall designs

- Xytron™ PPS allows for super high temperatrue resistance for long term.

- High Voltage Connector E-Motor Application Data

Details

Application requirements Electrical insulation High CTI 600 V UL94 V0 halogen-free Thermal cycles/shock resistant Material properties Low moisture uptake Chemical resistant Thermal cycles/fatigue Electric insulativeBenefits

- Robust (wire load) design

- Harsh environment

- Improved lifetime/safety vs PA66/PBT

- Reflow Connectors -3 Application Data

Details

PA46, PA4T excellent flow (> PEEK, PPA) PA4T low moisture absorptionBenefits

- Stanyl® PA46 and ForTii® PA4T allow for reliable solutions due to their high melting temperatures (allowing the use of high reflow temperatures) and high mechanical performance (implying a reduced reject rate during pin assembly + meeting mechanical specification also after reflow soldering)

- ForTii® PA4T increases the reliability even due to a high dimensional stability, a low and isotropic CLTE leading to high co-planarity and low warpage after soldering

- Stanyl® PA46 and ForTii® PA4T allow for cost effective solutions due to their ease of processability and flowability (enabling thin wall designs)

- HDMI Connectors Application Data

Details

PA4T good flow (> PPA, = LCP) PA4T low moisture absorptionBenefits

- ForTii® PA4T allows for reliable solutions due to its high melting temperature (ideal for reflow process), high mechanical performance (also after reflow soldering), a high dimensional stability (result from low, isotropic CLTE), a high co-planarity and low warpage after soldering, and good dielectrics due to low moisture uptake

- ForTii® PA4T allow for cost effective solutions to due good processability and high flowability enabling thin walled designs

- ForTii® PA4T allow for even more sustainable solutions with reduced environmental impact due to its lower carbon footprint as compared to alternative materials

- Reflow Connectors -2 Application Data

Details

PA46, PA4T excellent flow (> PEEK, PPA) PA4T low moisture absorptionBenefits

- Stanyl® PA46 and ForTii® PA4T allow for reliable solutions due to their high melting temperatures (allowing the use of high reflow temperatures) and high mechanical performance (implying a reduced reject rate during pin assembly + meeting mechanical specification also after reflow soldering)

- ForTii® PA4T increases the reliability even due to a high dimensional stability, a low and isotropic CLTE leading to high co-planarity and low warpage after soldering

- Stanyl® PA46 and ForTii® PA4T allow for cost effective solutions due to their ease of processability and flowability (enabling thin wall designs)

- Temperature Sensor Application Data

Details

Many different sensor types/systems: Hall-, ABS-, Oil-, MAF-, Air Bag-, Throttle- Sensor Crankshaft, Camshaft, ETC, Seat position.Benefits

- Stanyl® PA46, ForTii® PA4T, Akulon® PA66, Akulon® PA6, Arnite® PBT allow for reliable solutions due to high temperature resistance, high toughness levels and good electrical insulation properties

- Stanyl® PA46 allows for cost effective solutions due to a better flowability and processability than PPS and PPA enabling therefore thin wall designs

- ForTii® PA4T allows for reliable solutions exposed to very high peak temperatures due to its melting point of 325 C

- Medium Voltage Circuit Breakers Application Data

Details

Most grades are available with halogenfree flameretardancy, and in specific electro-gray color for housings. ForTii® has a Heat Deflection Temperature (HDT) of 305°C .Benefits

- ForTii® PA4T allows for more sustainable solutions in end-products due to lower CO₂ footprint as compared to solutions with epoxy Xlink agent

- ForTii® PA4T allows for potential system cost reduction opportunities due to part integration possibilities , possible thinner wall design withlower profiles possibilities, reduced cycle times with lower production losses

- Contactors Application Data

Details

Most grades are available with halogenfree flameretardancy, and in specific electro-gray color for housings. Also Lasermarkable grades are available. ForTii® has a Heat Deflection Temperature (HDT) of 305°C .Benefits

- Akulon® PA6 and ForTii® PA4T allow for reliable solutions due to good electrical and thermal endurance

- Akulon® PA6 and ForTii® PA4T allow for more design freedom and/or potential system cost reductions due to part integration and thinner wall design and lower profiles possibilities, reduced cycle time with lower production losses

- Industrial Control Gear Application Data

Details

Most grades are available with halogenfree flameretardancy, and in specific electro-gray color for housings. ForTii® Heat Deflection Temperature (HDT) of 305°C .Benefits

- Akulon® PA6 and ForTii® PA4T allow for reliable solutions due to good electrical and thermal endurance

- Akulon® PA6 and ForTii® PA4T allow for more design freedom and/or potential system cost reductions due to part integration and thinner wall design and lower profiles possibilities, reduced cycle time with lower production losses

- Start/Stop: Alternator and Starter Parts Application Data

Details

Stanyl® PA46 also used in connectors, e-motor parts, bobbins, sensors, fuse boxes.Benefits

- Stanyl® PA46 allows for reliable solutions due to a high temperature resistance and creep resistance at elevated temperatures, high toughness levels, excellent wear and friction behavior and good electrical insulation properties

- ForTii® PA4T allows for reliable solutions due to a very high peakt temperature resistance due to its melting point of 325 C

- Stanyl® PA46 and ForTii® PA4T allow for cost effective solutions due to a better flowability and processability than PPS and PPA enabling therefore thin wall designs

- Molded Case Circuit Breakers Application Data

Details

Most grades are available with halogenfree flameretardancy, and in specific electro-gray color for housings.Benefits

- Akulon® PA6, Stanyl® PA46 and ForTii® PA4T allow for reliable solutions due to up-to 30% improved electrical endurance compared to conventional materials

- Akulon® PA6, Stanyl® PA46 and ForTii® PA4T allow for more appealing solutions due to enhanced esthetics

- Akulon® PA6, Stanyl® PA46 and ForTii® PA4T allow for system cost reduction up to 15% compared to thermoset compounds due to potential reduction of wall thicknesses by up to 2/3rd and due to potential part integration possibilities

- FPC Connectors Application Data

Details

ForTii® offers a halogen-free alternative for ICT components that enables the latest interface technology with lower power consumption and provides higher efficiency, optimized performance and reduced environmental impact, including a lower carbon footprint vs. existing solutions and full compatibility with lead-free reflow soldering; ForTii® offers a unique balance of high melt temperature (325°C), High glass transition temperature (125°C), high stiffness and very low moisture absorption.Benefits

- Stanyl® PA46 and ForTii® PA4T allow for reliable solutions due to high stiffness even at elevated lead-free reflow assembly temperatures with hot spots up to 300°C

- Stanyl® PA46 and ForTii® PA4T allow for cost effective solutions due to very low warpage levels to minimizing rejects significantly therefore

- ForTii® PA4T allow for even more sustainable solutions with reduced environmental impact due to its lower carbon footprint as compared to alternative materials

- Motor Starter/Overload Relays Application Data

Details

Most grades are available with halogenfree flameretardancy, and in specific electro-gray color for housings. Also Lasermarkable grades are available. ForTii® has a Heat Deflection Temperature (HDT) of 305°C .Benefits

- Akulon® PA6, Arnite® PBT, Stanyl® PA46 and ForTii® PA4T allow for reliable solutions due to good electrical and thermal endurance

- Akulon® PA6, Arnite® PBT, Stanyl® PA46 and ForTii® PA4T allow for more design freedom and/or potential system cost reductions due to part integration and thinner wall design and lower profiles possibilities, reduced cycle time with lower production losses

- Miniature Circuit Breakers Application Data

Details

As they move away from halogenated thermoplastic and thermoset materials, producers of low voltage switchgear (LVSG) are turning to more environmentally friendly solutions. Manufacturers of miniature circuit breaker enclosures are now using halogen-free flame retardant Polyamide 6 (PA6).Benefits

- Akulon® PA6 allows for reliable solutions due to up to 30% improved electrical endurance compared to conventional materials

- Akulon® PA6 allows for more appealing solutions due to enhanced esthetics

- Akulon® PA6 allows for system cost reduction up to 15% compared to thermoset compounds due to potential reduction of wall thicknesses by up to 2/3rd and due to potential part integration possibilities

- Medium Voltage Circuit Breaker Isolators Application Data

Details

Most grades are available with halogenfree flameretardancy, and in specific electro-gray color for housings. ForTii® has a Heat Deflection Temperature (HDT) of 305°C .Benefits

- ForTii® PA4T allows for more sustainable solutions in end-products due to lower CO₂ footprint as compared to solutions with epoxy Xlink agent

- ForTii® PA4T allows for significant system cost reduction due to lower density up to 17% than conventional materials, part weight reduction up to 35%, cycle time down by factor 7

- MCCB Housings Application Data

Details

Most grades are available with halogenfree flameretardancy, and in specific electro-gray color for housings. ForTii® Heat Deflection Temperature (HDT) of 305°C .Benefits

- Akulon® PA6 and ForTii® PA4T enable increased design flexibility and integrated functionality, facilitating smart assembly solutions

- Akulon® PA6 and ForTii® PA4T allow for reliable solutions due to good dielectric aging performance at 150°C and high CTI values at 600 Volts

- Akulon® PA6 and ForTii® PA4T allow for potential system cost reductions up to 15% ( wall thicknesses reduced leading to a volume reduction of up to 25%) compared to conventional materials

- Battery Connectors Application Data

Details

Envalior offers a halogen-free alternative for ICT components that enables the latest interface technology with lower power consumption and provides higher efficiency, optimized performance and reduced environmental impact, including a lower carbon footprint vs. existing solutions and full compatibility with lead-free reflow soldering.Benefits

- Stanyl® PA46 and ForTii® PA4T allow for reliable solutions due to their high-heat resistance, a unique balance of high stiffness and good flowability and high strength and creep resistance levels leading to good pin retention

- Stanyl® PA46 and ForTii® PA4T allow for cost effective solutions to due good processability and high flowability enabling thin walled designs

- Micro Appliance Connector Application Data

Details

Micro dual locking latch for the applicationBenefits

- Better stiffness and toughness enhance

- Dual locking latch performance

- Reduce cracking rate down to 0%

- Lowering system costs

Properties

- Flame Rating

- Mechanical Properties

Value Units Test Method / Conditions Tensile Modulus 11500 / 12000 MPa ISO 527-1/-2 Tensile Modulus (-40°C) 12000 / - MPa ISO 527-1/-2 Tensile Modulus (40°C) 11300 / - MPa ISO 527-1/-2 Tensile Modulus (80°C) 10800 / 7600 MPa ISO 527-1/-2 Tensile Modulus (100°C) 10000 / - MPa ISO 527-1/-2 Tensile Modulus (120°C) 8000 / - MPa ISO 527-1/-2 Tensile Modulus (140°C) 5700 / * MPa ISO 527-1/-2 Tensile Modulus (160°C) 5000 / * MPa ISO 527-1/-2 Tensile Modulus (Low Thickness, 1mm) 10700 / - MPa ISO 527-1/-2 Stress at Break 150 / 140 MPa ISO 527-1/-2 Stress at Break (-40°C) 175 / - MPa ISO 527-1/-2 Stress at Break (40°C) 145 / - MPa ISO 527-1/-2 Stress at Break (80°C) 125 / 85 MPa ISO 527-1/-2 Stress at Break (100°C) 115 / - MPa ISO 527-1/-2 Stress at Break (120°C) 100 / - MPa ISO 527-1/-2 Stress at Break (140°C) 80 / * MPa ISO 527-1/-2 Stress at Break (160°C) 70 / * MPa ISO 527-1/-2 Stress at Break, at low thickness 160 / - MPa ISO 527-1/-2 Stress at Break (Thickness tested) 1 / - mm ISO 527-1/-2 Strain at Break 2 / 1.9 % ISO 527-1/-2 Strain at Break (at -40°C) 2.2 / - % ISO 527-1/-2 Strain at Break (at 40°C) 1.9 / - % ISO 527-1/-2 Strain at Break (at 80°C) 1.9 / 2.9 % ISO 527-1/-2 Strain at Break (at 100°C) 2 / - % ISO 527-1/-2 Strain at Break (at 120°C) 2.6 / - % ISO 527-1/-2 Strain at Break (at 140°C) 3.3 / * % ISO 527-1/-2 Strain at Break (at 160°C) 3.8 / * % ISO 527-1/-2 Strain at Break, at low thickness 2.1 / - % ISO 527-1/-2 Strain at Break (Thickness tested) 1 / - mm ISO 527-1/-2 Flexural Modulus 11000 / 11500 MPa ISO 178 Flexural Modulus (at 80°C) 10500 / 7600 MPa ISO 178 Flexural Modulus (at 120°C) 8200 / * MPa ISO 178 Flexural Modulus (at 160°C) 5000 / * MPa ISO 178 Flexural Strength 245 / 220 MPa ISO 178 Flexural Strength (at 80°C) 190 / 130 MPa ISO 178 Flexural Strength (at 120°C) 150 / * MPa ISO 178 Flexural Strength (at 160°C) 100 / * MPa ISO 178 Charpy Impact Strength (at +23°C) 50 / 50 kJ/m² ISO 179/1eU Charpy Notched Impact Strength (at +23°C) 7.5 / 7.5 kJ/m² ISO 179/1eA Weldline Strength (at thickness 4 / * mm) 50 / 140 MPa ISO 527-1/-2 Weldline Strain (at thickness 4 / * mm) 0.6 / 1.8 % ISO 527-1/-2 Weldline Strength (at thickness 1 / * mm) 60 / - MPa ISO 527-1/-2 Weldline Strain (at thickness 1 / * mm) 0.7 / - % ISO 527-1/-2 - Thermal Properties

Value Units Test Method / Conditions Melting Temperature (10°C/min) 325 / * °C ISO 11357-1/-3 Glass Transition Temperature (at 10°C/min) 125 / * °C ISO 11357-1/-2 Temperature of Deflection Under Load (1.80 MPa) 305 / * °C ISO 75-1/-2 Temperature of Deflection Under Load (0.45 MPa) 323 / * °C ISO 75-1/-2 Coefficient of Linear Thermal Expansion (parallel) 0.2 / * E-4/°C ISO 11359-1/-2 Coefficient of Linear Thermal Expansion (parallel) 0.3 / * E-4/°C ASTM D696 Coefficient of Linear Thermal Expansion (normal) 0.65 / * E-4/°C ISO 11359-1/-2 Coefficient of Linear Thermal Expansion (normal) 0.35 / * E-4/°C ASTM D696 Thermal Conductivity in Plane 0.4 / * W/(m K) ASTM E1461 Burning Behaviour (at 1.5 mm Nominal Thickness) UL V-0 / * class IEC 60695-11-10 Burning Behaviour (at 3.0 mm Nominal Thickness) UL V-0 / * class IEC 60695-11-10 Burning Behaviour (at 0.2 mm Thickness h) UL V-0 / * class IEC 60695-11-10 Oxygen Index 39 / * % ISO 4589-1/-2 Ball Pressure Temperature 305 / * °C IEC 60695-10-2 Glow Wire Flammability Index (at thickness 3 / - mm) 960 / - °C IEC 60695-2-12 Glow Wire Flammability Index (at thickness 0.25 / - mm) 960 / - °C IEC 60695-2-12 Glow Wire Ignition Temperature (at thickness 3 / - mm) 800 / - °C IEC 60695-2-13 Glow Wire Ignition Temperature (at thickness 0.75 / - mm) 800 / - °C IEC 60695-2-13 Relative Temperature Index (Electrical, 0.75 / * mm) 140 / * °C UL746B Relative Temperature Index (Electrical, 0.2 / * mm) 130 / * °C UL746B Relative Temperature Index (with impact, 0.35 / * mm) 130 / * °C UL746B Relative Temperature Index (with impact, 3 / * mm) 130 / * °C UL746B Relative Temperature Index (without impact, 0.35 / * mm) 130 / * °C UL746B Relative Temperature Index (without impact, 3 / * mm) 130 / * °C UL746B Thermal Index (2500 hrs) 181 / * °C IEC 60216/ISO 527-1/-2 Thermal Index (5000 hrs) 170 / * °C IEC 60216/ISO 527-1/-2 Thermal Index (10000 hrs) 159 / * °C IEC 60216/ISO 527-1/-2 Thermal Index (20000 hrs) 149 / * °C IEC 60216/ISO 527-1/-2 - Electrical Properties

Value Units Test Method / Conditions Relative Permittivity (100Hz) 4.2 / 4.2 - IEC 62631-2-1 Relative Permittivity (1 MHz) 3.9 / 3.9 - IEC 62631-2-1 Relative Permittivity (1GHz) 3.8 / 3.9 - IEC 60250 Relative Permittivity (10GHz) 3.8 / 3.9 - IEC 60250 Dissipation Factor (100 Hz) 64 / 64 E-4 IEC 62631-2-1 Dissipation Factor (1 MHz) 176 / 176 E-4 IEC 62631-2-1 Dissipation Factor (1GHz) 130 / 130 E-4 IEC 60250 Dissipation Factor (10GHz) 110 / 130 E-4 IEC 60250 Volume Resistivity >1E13 / >1E13 Ohm*m IEC 62631-3-1 Surface Resistivity - / >1E15 Ohm IEC 62631-3-2 Electric Strength 33 / 33 kV/mm IEC 60243-1 Comparative Tracking Index 600 / - V IEC 60112 - Material Specific Properties

Value Units Test Method / Conditions Viscosity Number 86 / * cm³/g ISO 307, 1157, 1628 - Other Properties

Value Units Test Method / Conditions Water Absorption 4.1 / * % Sim. to ISO 62 Water Absorption in Water (at 23°C after 24h) 0.3 / * % ISO 62 Humidity Absorption 1.6 / * % Sim. to ISO 62 Density 1460 / - kg/m³ ISO 1183 - Rheological Properties

Value Units Test Method / Conditions Molding Shrinkage (parallel) 0.35 / * % ISO 294-4 Molding Shrinkage (normal) 1.2 / * % ISO 294-4 Spiral Flow Length 1.0 mm 800 bar 110 / * mm - Spiral Flow Length 1.0 mm 900 bar 120 / * mm - Spiral Flow Length 1.0 mm 1000 bar 130 / * mm -

Regulatory & Compliance

- Certifications & Compliance

- Quality Standards

Technical Details & Test Data

- Chemical Resistance

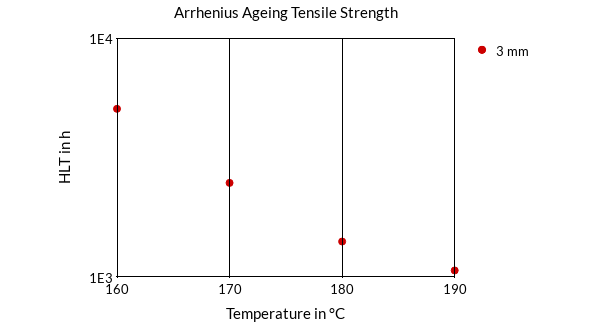

Chemical Type Chemical Name Resistance Other Acetaldehyde (40% by mass) at 23°C limited resistant, tests necessary to verify Other Acetamide (50% by mass) at 23°C limited resistant, tests necessary to verify Other Acetamide (50% by mass) at >140°C not resistant Other Acetic acid (10% by mass) at 100°C not resistant Other Acetic acid (10% by mass) at 23°C limited resistant, tests necessary to verify Other Acetic acid (95% by mass) at 23°C not resistant Other Acetic anhydride limited resistant, tests necessary to verify Ketones Acetone at 23°C resistant Other Acetonitrile resistant Other Acetophenone at 23°C resistant Other Acetyl chloride at 23°C not resistant Other Acetylene at 23°C resistant Other Acrylic acid at 23°C not resistant Other AdBlue® resistant Other Aliphatic amines at 23°C resistant Other Aliphatic hydrocarbons at 23°C resistant Other Alkylbenzenes at 23°C resistant Other Allyl alcohol at 23°C limited resistant, tests necessary to verify Other Aluminum acetate (saturated) at 23°C resistant Other Aluminum chloride (10% by mass) at 23°C resistant Other Aluminum hydroxide (saturated) at 23°C resistant Other Aluminum salts of mineral acids (saturated) at 23°C limited resistant, tests necessary to verify Other Aluminum trichloride (10% by mass) at 23°C resistant Other Amino acids (saturated) at 23°C resistant Other Ammonia at 23°C resistant Other Ammonium chloride (35% by mass) at 100°C limited resistant, tests necessary to verify Other Ammonium chloride (35% by mass) at 23°C resistant Other Ammonium salts of mineral acids (10% by mass) at 23°C resistant Other Ammonium salts of mineral acids (10% by mass) at 50°C limited resistant, tests necessary to verify Other Ammonium thiocyanate (saturated) at 23°C resistant Other Amyl acetate at 100°C not resistant Other Amyl acetate at 23°C resistant Other Amyl alcohol at 23°C resistant Other Aniline at 23°C not resistant Other Anodizing liquid (HNO3/H2SO4) at 23°C limited resistant, tests necessary to verify Other Antimony trichoride (saturated) at 23°C not resistant Other Aqua Regia (HCl/HNO3) at 23°C not resistant Other Aromatic hydrocarbons at 23°C resistant Other Bariumsalts of mineral acids at 23°C limited resistant, tests necessary to verify Other Benzaldehyde at 23°C limited resistant, tests necessary to verify Other Benzene at 23°C resistant Other Benzene at 80°C resistant Other Benzoic acid (20% by mass) at 23°C limited resistant, tests necessary to verify Other Benzoic acid (saturated) at 23°C not resistant Other Benzyl alcohol at 23°C limited resistant, tests necessary to verify Other Beverages at 23°C resistant Other Bleaching agent (NaOCl) at 23°C not resistant Other Boric acid (10% by mass) at 23°C limited resistant, tests necessary to verify Other Boron trifluoride at 23°C not resistant Other Brake fluids (DOT 3/4) at 23°C limited resistant, tests necessary to verify Other Bromine water (saturated) at 23°C not resistant Other Bromochlorodifluoromethane at 23°C resistant Other Bromotrifluoromethane at 23°C resistant Other Butadiene at 23°C resistant Other Butane at 23°C resistant Other Butanediols at 23°C resistant Other Butanediols at >140°C limited resistant, tests necessary to verify Other Butanols at 23°C resistant Other Butene glycol at 23°C resistant Other Butene glycol at >160°C limited resistant, tests necessary to verify Other Butene-1 at 23°C resistant Other Butter at 23°C resistant Other Butyl acetate at 23°C resistant Other Butyl acrylate at 23°C resistant Other Butyl glycolate at 23°C resistant Other Butyl phthalate at 23°C resistant Other Butyric acid (20% by mass) at 23°C limited resistant, tests necessary to verify Other Butyrolactone at 23°C resistant Other Butyrolactone at >90°C limited resistant, tests necessary to verify Other Calcium chloride (10% by mass) at 100°C limited resistant, tests necessary to verify Other Calcium chloride (10% by mass) at 23°C resistant Other Calcium chloride (alcoholic) (20% by mass) at 23°C limited resistant, tests necessary to verify Other Calcium chloride (saturated) at 100°C not resistant Other Calcium chloride (saturated) at 23°C resistant Other Calcium chloride (saturated) at 60°C limited resistant, tests necessary to verify Other Calcium hydroxide (saturated) at 23°C resistant Other Calcium hypochloride (saturated) at 23°C not resistant Other Camphor (alcoholic) (50% by mass) at 23°C resistant Other Caprolactam (50% by mass) at 23°C resistant Other Caprolactam (50% by mass) at >150°C limited resistant, tests necessary to verify Other Carbon disulfide at 23°C resistant Other Carbon disulfide at 60°C not resistant Other Carbon tetrachloride at 23°C resistant Other Casein at 23°C resistant Other Chloral hydrate at 23°C not resistant Other Chloramines (10% by mass) at 23°C not resistant Other Chlorinated biphenyls at 80°C limited resistant, tests necessary to verify Other Chlorine water at 23°C not resistant Other Chloroacetic acid (10% by mass) at 23°C not resistant Other Chlorobenzene at 23°C resistant Other Chlorobenzene at 50°C resistant Other Chlorobromomethane at 23°C limited resistant, tests necessary to verify Other Chlorodifluoroethane at 23°C resistant Other Chlorodifluoromethane at 23°C resistant Other Chlorofluoroethylene at 23°C resistant Other Chloroform at 23°C not resistant Other Chlorosulfonic acid (10% by mass) at 23°C not resistant Other Chromic acid (1% by mass) at 23°C limited resistant, tests necessary to verify Other Chromic acid (10% by mass) at 23°C not resistant Other Chromyl chloride at 23°C not resistant Other cis-2-butene at 23°C resistant Other Citric acid (10% by mass) at 23°C resistant Other Citric acid (20% by mass) at 80°C limited resistant, tests necessary to verify Other Cobalt salt (20% by mass) at 23°C limited resistant, tests necessary to verify Other Copper sulfate (10% by mass) at 23°C resistant Other Copper(II) salt (10% by mass) at 23°C limited resistant, tests necessary to verify Other Cresols at 23°C not resistant Other Cycloalcohols (incl their esters) at 23°C resistant Other Cycloalkanes at 23°C resistant Other Cycloalkanones at 23°C resistant Other Cyclohexanol at 23°C limited resistant, tests necessary to verify Other Decalin at 23°C resistant Other Developer (photografic) at 23°C resistant Other Dibutyl phthalate at 23°C resistant Other Dibutyl phthalate at 60°C resistant Other Dichlorobenzene at 23°C resistant Other Dichloroethane at 23°C resistant Other Dichloroethylene at 23°C resistant Other Dichlorofluoromethane at 23°C resistant Other Dichlorotetrafluoroethane at 23°C resistant Ethers Diethyl ether at 23°C resistant Other Diethylene glycol at 23°C resistant Other Diethylene glycol at >140°C not resistant Other Difluoromethane at 23°C resistant Other Dimethyl acetamide at 23°C resistant Other Dimethyl acetamide at >150°C not resistant Other Dimethyl ether at 23°C resistant Other Dimethylamine at 23°C resistant Other Dimethylformamide at 23°C resistant Other Dimethylformamide at 90°C limited resistant, tests necessary to verify Other Dimethylsilane at 23°C resistant Other Dimethylsulfoxide at 125°C not resistant Other Dimethylsulfoxide at 23°C resistant Other Dioctyl phtalate at 23°C resistant Other Dioxan at 23°C resistant Other Dioxan at 60°C resistant Other Diphenyl ether at 80°C resistant Other Dipropyl ether at 23°C resistant Other Edible fats waxes and oils at 100°C resistant Other Electroplating bath (acidic) at 23°C not resistant Other Electroplating bath (alkali) at 23°C resistant Other Ethane at 23°C resistant Alcohols Ethanol at 23°C resistant Other Ethyl Acetate at 23°C resistant Other Ethyl chloride at 23°C resistant Other Ethylbenzen at 23C resistant Other Ethylene at 23°C resistant Other Ethylene carbonate at 100°C not resistant Other Ethylene carbonate at 50°C resistant Other Ethylene chlorohydrin at 23°C limited resistant, tests necessary to verify Other Ethylene glycol at 100°C not resistant Other Ethylene glycol at 23°C resistant Other Ethylene oxide at 23°C resistant Other Ethylene oxide at >80°C not resistant Other Ethylenediamine at 23°C resistant Other Fatty acids at 23°C resistant Other Fatty alcohols at 23°C resistant Other Ferric chloride (2,5% by mass) at 100°C not resistant Other Ferric chloride (2,5% by mass) at 23°C limited resistant, tests necessary to verify Other Fixer (photografic) at 23°C resistant Other Fluorinated hydrocarbons at 70°C resistant Other Fluorine at 23°C not resistant Other Formaldehyde (30% by mass) at 23°C resistant Other Formamide at 23°C resistant Other Formamide at >150°C not resistant Other Formic acid (10% by mass) at 23°C not resistant Other Formic acid (10% by mass) at 50°C not resistant Other Fruit juices at 23°C resistant Other Fuel; Diesel at 85°C resistant Other Fuel; FAM 1A at 23°C resistant Other Fuel; FAM 2A at 23°C resistant Other Fuel; Gasoline at 85°C resistant Other Fuel; LPG at 23°C resistant Other Furfural at 23°C resistant Other Furfuryl alcohol at 23°C resistant Other Glucose at 23°C resistant Other Glycerol at 170°C resistant Other Glycerol at 23°C resistant Other Glycol-water 50/50 mixture resistant Other Glycolic acid (30% by mass) at 23°C resistant Other Glycols at 23°C resistant Other Grease (based on ester oils) at <100°C resistant Other Grease (based on metal soaps) at <100°C resistant Other Grease (based on polyphenylester) at <100°C resistant Other Hardening oils at 23°C resistant Other Heating oils at 23°C resistant Other Heptane at 23°C resistant Other Hexachlorobenzene at 80°C resistant Other Hexachloroethane at 23°C resistant Other Hexafluoroisopropanol at 23°C not resistant Other Hexane at 23°C resistant Other Hydraulic fluids at 100°C resistant Other Hydrobromic acid (10% by mass) at 23°C not resistant Other Hydrochloric acid (10% by mass) at 23°C not resistant Other Hydrochloric acid (20% by mass) at 23°C not resistant Other Hydrochloric acid (conc.% by mass) at 23°C not resistant Other Hydrofluoric acid (40% by mass) at 23°C resistant Other Hydrofluoric acid (5% by mass) at 23°C not resistant Other Hydrogen at 23°C resistant Other Hydrogen peroxide (0.5% by mass) at 23°C limited resistant, tests necessary to verify Other Hydrogen peroxide (1% by mass) at 23°C not resistant Other Hydrogen peroxide (3% by mass) at 23°C not resistant Other Hydrogen peroxide (30% by mass) at 23°C not resistant Other Hydrogen sulfide (10% by mass) at 23°C limited resistant, tests necessary to verify Other Hydroiodic acid at 23°C not resistant Other Hydroquinone (5% by mass) at 23°C not resistant Other Impregnating oils at 23°C resistant Other Ink at 23°C resistant Other Iodine (alcoholic) at 23°C not resistant Other Iron(III)chloride (acidic) (10% by mass) at 23°C not resistant Other Iron(III)chloride (neutral) (10% by mass) at 23°C resistant Other Iron(III)chloride (saturated) at 23°C not resistant Other Iron(III)thiocyanate (10% by mass) at 23°C limited resistant, tests necessary to verify Other Isocyanates (aromatic) at 23°C resistant Other Isooctane at 80°C resistant Other Isopropanol at 23°C resistant Other Isopropanol at 60°C resistant Other Kerosene resistant Other Ketones (aliphatic) at 23°C resistant Other Lactic acid at 10°C resistant Other Lactic acid at 90°C not resistant Other Lead acetate (10% by mass) at 23°C resistant Other Linseed oil at 23°C resistant Other Lithium bromide (10% by mass) at 23°C limited resistant, tests necessary to verify Other Lithium chloride (20% by mass) at 23°C not resistant Other Lithium hydroxide (10% by mass) at 23°C resistant Other Lithium hydroxide (10% by mass) at 80°C not resistant Other Lubricating oil (gear) at <130°C resistant Other Lubricating oil (hydraulics) at <130°C resistant Other Lubricating oil (transformers) at <130°C resistant Other Magnesium hydroxide (10% by mass) at 23°C resistant Other Magnesium salts (10% by mass) at 23°C resistant Other Maleic acid (25% by mass) at 23°C limited resistant, tests necessary to verify Other Maleic acid (saturated) at 23°C resistant Other Manganese salts (10% by mass) at 23°C resistant Other Mercury at 23°C resistant Other Mercury(II)chloride (saturated) at 23°C not resistant Other Methane at 23°C resistant Alcohols Methanol at 23°C resistant Other Methyl acetate at 23°C resistant Other Methyl chloride at 23°C resistant Other Methyl ethyl ketone at 23°C resistant Other Methyl formate at 23°C resistant Other Methyl glycol at 23°C resistant Other Methylamine at 23°C resistant Other Methylaniline at 23°C resistant Other Methylbromide at 23°C resistant Other Methylene chloride at 23°C limited resistant, tests necessary to verify Other Methylpyrrolidone at 23°C resistant Other Milk at 23°C resistant Other n-Butyl ether at 23°C resistant Other n-Butyl glycol at 23°C resistant Other Naphtha at 23°C resistant Other Naphthalene at 23°C resistant Other Naphthalenesulfonic acids at 23°C not resistant Other Naphthenic acids at 23°C resistant Other Naphthols at 23°C not resistant Other Nickel nitrate (10% by mass) at 23°C limited resistant, tests necessary to verify Other Nickel salts (10% by mass) at 23°C resistant Other Nitric acid (10% by mass) at 23°C not resistant Other Nitric acid (2% by mass) at 23°C not resistant Other Nitric acid (20% by mass) at 23°C not resistant Other Nitric acid (conc.% by mass) at 23°C not resistant Other Nitrobenzene at 23°C limited resistant, tests necessary to verify Other Nitrobenzene at >100°C not resistant Other Nitrocellulose lacquers (alcoholic) at 23°C limited resistant, tests necessary to verify Other Nitrocellulose lacquers (non-alcoholic) at 23°C resistant Other Nitrogen oxides at 23°C limited resistant, tests necessary to verify Other Nitromethane at 23°C limited resistant, tests necessary to verify Other Nitropropane at 23°C limited resistant, tests necessary to verify Other Nitrotoluene at 23°C limited resistant, tests necessary to verify Other Nitrotoluene at >100°C not resistant Other Nitrous fumes at 23°C limited resistant, tests necessary to verify Other Nitrous oxide at 23°C resistant Other Octane at 23°C resistant Other Octene at 23°C resistant Other Oil (Shell 10W40) at 23°C resistant Other Oil (transformers, switchgear) at 50°C resistant Other Oils (vegatable, mineral, ethereal) at 23°C resistant Other Oleic acid at 23°C resistant Other Oleum (H2SO4+SO3) at 23°C not resistant Other Oxalic acid (10% by mass) at 23°C limited resistant, tests necessary to verify Other Oxalic acid (10% by mass) at 80°C not resistant Other Ozone at 23°C not resistant Other Paint solvents at 23°C resistant Other Palmatic acid at 80°C resistant Other Paraffin at 23°C resistant Other Peracetic acid at 23°C not resistant Other Perchloric acid (10% by mass) at 23°C not resistant Other Petroleum at 23°C resistant Other Petroleum ether and solvents at 80°C resistant Other Phenol (alc. sol.) (70% by mass) at 23°C limited resistant, tests necessary to verify Other Phenol (conc.% by mass) at 23°C not resistant Other Phenol at >40°C not resistant Other Phenyl ether at 23°C not resistant Other Phenyl ethyl alcohol at 23°C limited resistant, tests necessary to verify Other Phenyl ethyl alcohol at >160°C not resistant Other Phosphate sol. (neutral, alkaline) (10% by mass) at 23°C resistant Other Phosphine at 23°C resistant Other Phosphoric acid (10% by mass) at 23°C not resistant Other Phosphoric acid (conc.% by mass) at 23°C not resistant Other Phthalic acid (saturated) at 23°C limited resistant, tests necessary to verify Other Polyols at 23°C resistant Other Potassium bromide (10% by mass) at 23°C limited resistant, tests necessary to verify Other Potassium chlorate (7% aquous solution) at 23C not resistant Other Potassium chloride (10% by mass) at 23°C resistant Other Potassium chloride (10% by mass) at 70°C resistant Other Potassium dichromate (5% by mass) at 23°C limited resistant, tests necessary to verify Other Potassium hydroxide (50% by mass) at 23°C limited resistant, tests necessary to verify Other Potassium nitrate (10% by mass) at 23°C resistant Other Potassium permanganate (1% by mass) at 23°C not resistant Other Potassium thiocyanate (saturated) at 23°C not resistant Other Propane at 23°C resistant Other Propanol at 23°C resistant Other Propanol at >100°C not resistant Other Propene at 23°C resistant Other Propionic acid (5% by mass) at 23°C resistant Other Propionic acid (50% by mass) at 23°C not resistant Other Pyridine at 23°C resistant Other Pyridine at 80°C limited resistant, tests necessary to verify Other Pyrocatechol at 23°C not resistant Other Pyrrolidone at 23°C resistant Other Pyruvic acid (10% by mass) at 23°C limited resistant, tests necessary to verify Other Rainwater (acidic) at 23°C resistant Other Refrigerator oil at 23°C resistant Other Resorcinol (alcoholic) (1% by mass) at 23°C not resistant Other Road salts at 23°C resistant Other Salicylic acid (saturated) at 23°C resistant Other Seawater at 23°C resistant Other Silane at 23°C resistant Other Silicone oils at <80°C resistant Other Silicone oils at >100°C limited resistant, tests necessary to verify Other Silver nitrate (10% by mass) at 23°C resistant Other Soap solution (10% by mass) at 80°C resistant Other Sodium bichromate (10% by mass) at 23°C resistant Other Sodium bichromate (5% by mass) at 23°C resistant Other Sodium bromide (10% by mass) at 23°C limited resistant, tests necessary to verify Other Sodium cabonate (20% by mass) at 100°C limited resistant, tests necessary to verify Other Sodium carbonate (10% by mass) at 23°C resistant Other Sodium chlorate (10% by mass) at 23°C resistant Other Sodium chloride (10% by mass) at 23°C resistant Other Sodium chloride (saturated) at 23°C resistant Other Sodium chlorite (10% by mass) at 23°C limited resistant, tests necessary to verify Other Sodium cyanide (10% by mass) at 23°C resistant Other Sodium dichromate (10% by mass) at 23°C resistant Other Sodium dodecylbenzenesulfonate at 23°C resistant Other Sodium hydrogen carbonate (10% by mass) at 23°C resistant Other Sodium hydrogen sulfate (10% by mass) at 23°C resistant Other Sodium hydrogen sulfite (10% by mass) at 23°C resistant Other Sodium hydroxide (10% by mass) at 23°C resistant Other Sodium hydroxide (10% by mass) at 80°C not resistant Other Sodium hydroxide (50% by mass) at 23°C limited resistant, tests necessary to verify Other Sodium hypochlorite (10% by mass) at 23°C limited resistant, tests necessary to verify Other Sodium hypophosphite (10% by mass) at 23°C resistant Other Sodium lauryl sulfate (30% by mass) at 23°C resistant Other Sodium lignosulfonate at 23°C resistant Other Sodium nitrilotriacetate (10% by mass) at 23°C resistant Other Sodium oleate at 23°C resistant Other Sodium pentachlorophenolate at 23°C resistant Other Sodium pyrosulfite (10% by mass) at 23°C resistant Other Sodium salts (nitrate, sulfate) (10% by mass) at 23°C resistant Other Stearate at 23°C resistant Other Stearic acid at 23°C resistant Other Styrene at 80°C resistant Other Sulfonates (10% by mass) at 23°C resistant Other Sulfur at 23°C resistant Other Sulfur dioxide (dry) at 23°C resistant Other Sulfur dioxide (moist) at 23°C limited resistant, tests necessary to verify Other Sulfur hexafluoride at 23°C resistant Other Sulfuric acid (2% by mass) at 23°C not resistant Other Sulfuric acid (30% by mass) at 23°C not resistant Other Sulfuric acid (50% by mass) at 23°C not resistant Other Sulfuric acid (conc.% by mass) at 23°C not resistant Other Sulfurous acid (saturated) at 23°C limited resistant, tests necessary to verify Other Tartaric acid (10% by mass) at 23°C resistant Other Tartaric acid (50% by mass) at 23°C limited resistant, tests necessary to verify Other Tetrachloroethylene at 23°C limited resistant, tests necessary to verify Other Tetrachloroethylene at 80°C not resistant Other Tetrachloromethane at 23°C resistant Other Tetrafluoromethane at 23°C resistant Other Tetrafluoropropanol at 23°C not resistant Other Tetrahydrofuran at 23°C resistant Other Tetralin at 23°C resistant Other Tetramethylenesulfone at 23°C resistant - Arrhenius Ageing Tensile Strength

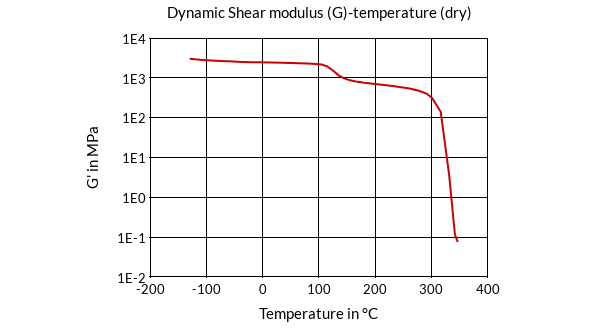

- Dynamic Shear Modulus (G)-Temperature (dry)

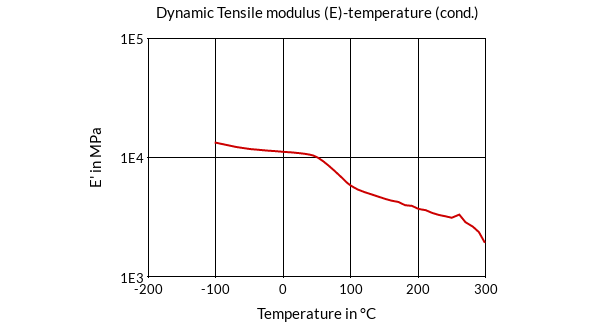

- Dynamic Tensile Modulus (E)-Temperature (cond.)

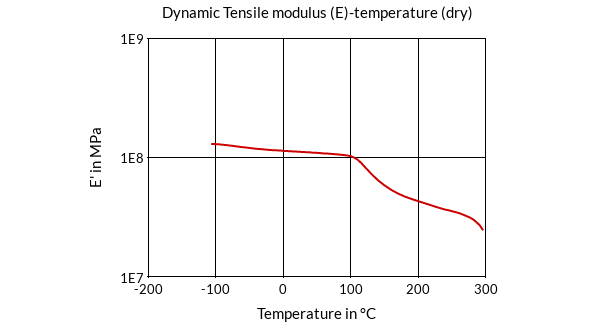

- Dynamic Tensile Modulus (E)-Temperature (dry)

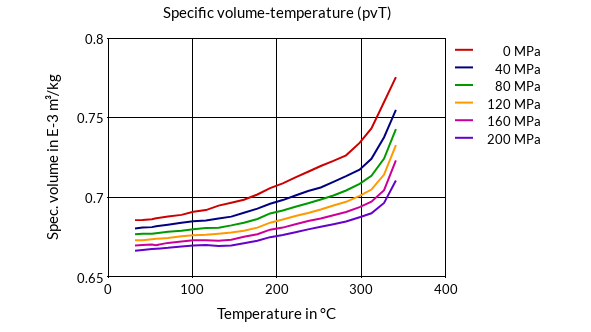

- Specific Volume-Temperature (pvT)

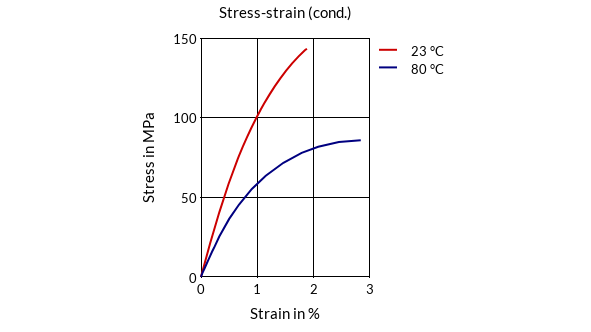

- Stress-Strain (cond.)

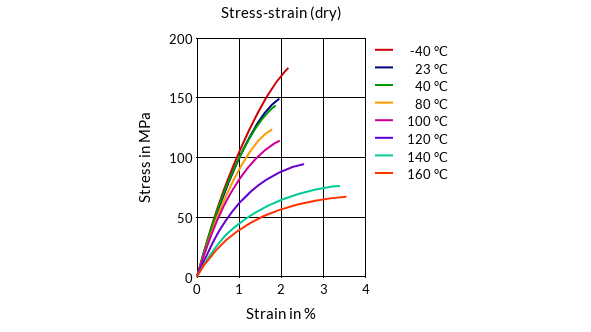

- Stress-Strain (dry)

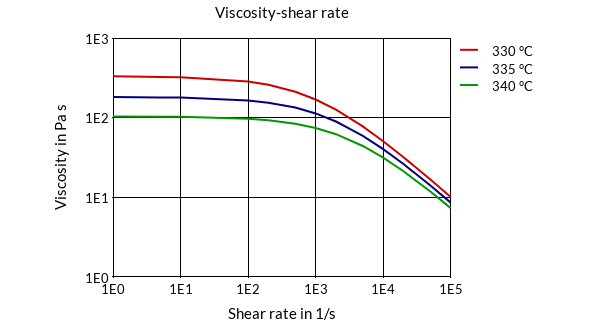

- Viscosity-Shear Rate

Packaging & Availability

- Packaging Type