Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Carrier

- Chemical Family

- Chemical Name

- CASE Ingredients Functions

- Technologies

- Product Families

- Product Functions

- Ready-to-use, liquid-form antiflash-rust additive for any waterborne coating.

- Hydrophobic agent protecting the almost dry film under severe conditions of ambient humidity.

- Corrosion inhibitor for metal packaging protection.

- Chemical Nature

Aqueous preparation made of organic acid salts and azole derivatives. Contains less than 5% of sodium nitrite.

Features & Benefits

- Labeling Claims

- CASE Ingredients Features

- Product Features

- Ready-to-use aqueous liquid

- VOC-free

- Doesn’t lead to water sensitivity of the coating

- Usable in labeled (with a max dosage of 1%) paints

- Usable for ferrous and non-ferrous metals (aluminum, copper, zinc, brass)

- Compatible with a very wide range of binders (acrylics, stirene-acrylic, epoxy, PU, alkyds, …)

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Compatible Substrates & Surfaces

- Adhesive & Sealant End Applications

- Coating End Applications

- Dosage

- Can be added at any manufacturing step.

- Can be post-added.

- In 2K systems: should be added in the resin part in most cases (to be checked with preliminary testing).

- Indicative use dosages (% of total coating weight):

- 0.1 to 0.3% on degreased substrates, not rusted, sand-blasted or not.

- 0.3 to 1.0% on cast-iron or rusted substrates, on welds.

- 0.3 to 1.5% for packaging protection.

- Above dosages can be increased when the coating is applied in severe conditions of ambient humidity.

- General Formulation Guidelines

- Incorporation via pre- or post-addition possible

- Efficient mixing required

- Addition SIFLOC D below 80°C

- Addition of key fabric softener ingredients at a temperature that is not below the melting point of the softener active. The dye, preservative and fragrance ingredients are typically added at the end at a lower temperature.

- Typical incorporation levels:

- 0.1 to 0.5% product as supplied in fabric rinse conditioners

- 0.5 to 5.0% product as supplied in acidic cleaners

Properties

- Physical Form

- Appearance

- Pale yellow limpid liquid

- Miscible in

- Water, Ethanol, Ethylene glycol, Butylglycol, Dipropylene glycol methyl ether (up to 2%)

- Immiscible In

- Methyl ethyl ketone, Isopropanol

- Typical Properties

Value Units Test Method / Conditions Density (at 20°C) 1.12 - 1.16 - - pH Value (at 20°C, Pure) 7.5 - 8.1 Viscosity (at 20°C) max. 30 cPs - Freezing Point max. 0 °C - Volatile Organic Compounds 0.0 % 2004-42-CE

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Technical Details & Test Data

- Antiflash - Rust Performance

ASCOTRAN® H14 additives provide highest levels of flash-rust inhibition at low use dosages. It outperform high nitrite-containing additives or usual flash-rust inhibitors, even when film dries under severe humidity conditions.

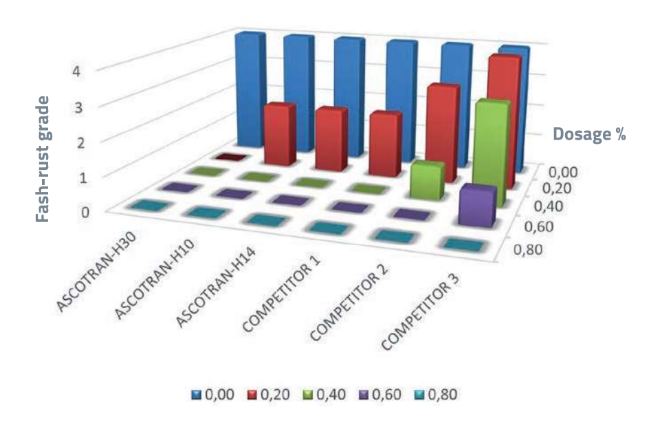

- Flash-rust comparative* test into a 1K Water-based Acrylic DTM Application on cold-rolled steel under normal drying conditions

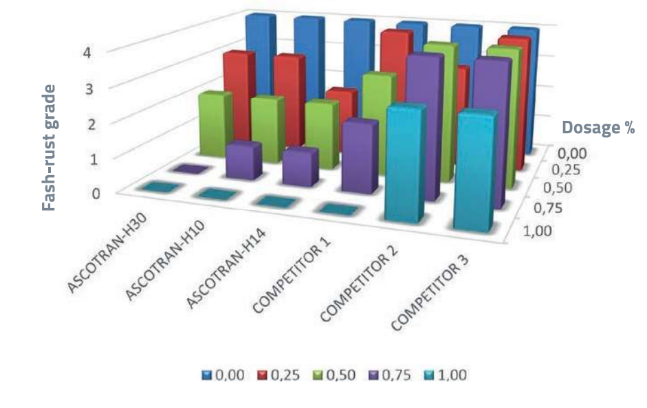

- Flash-rust comparative* test into a 1K Water-based Acrylic DTM Application on sand-blasted cast-iron under severe drying conditions

Note - * COMPETITORS 1, 2 and 3 are high nitrite-content additives.

- Preserve Film Water Resistance

Whereas usual flash-rust inhibitors reduce coatings water-resistance, the ASCOTRAN® H14 technology combines excellent antiflash-rust performance with hydrophobic properties.

- WB 2K EPOXY PRIMER

- ASTM D870 (40°C) 250H, DFT 70 um, CRS

- Dosage in Flash-Rust Inhibitor: 0.5%

- WB 1K ACRYLIC PRIMER

- DFT - 70 um, GRIT BLASTED CAST-IRON DRYING 2H UNDER A CAP + at FREE RT

- Dosage in Flash-Rust Inhibitor : 1%

- Packaging Protection

Coatings can be highly corrosive and can cause, in most cases, corrosion of metallic cans which contain them. ASCOTRAN® flash-rust inhibitors also provide in-can protection.

- Mechanism Liquid Dispersion Polymers (LDP)

- A Liquid Dispersion Polymer is a dispersion of microparticles in a non-aqueous carrier phase and a non-ionic activating surfactant

- Upon addition to water, the activating surfactant emulsifies the carrier phase and water swells the polymer particle by osmosis

- The apparent viscosity depends on the amount of available water and the osmotic pressure

Packaging & Availability

- Packaging Type

- Packaging Information

- Plastic pail of 30kg net.

- Metal drum of 200kg net.

- IBC of 1000 kg net.

Transport

Weight and packaging size (off-pallet) :- Pail: 1,5kg - Ø30, H50

- Drum: 15kg - Ø60, H90

- IBC: 70kg - L120, l100, H120

Storage & Handling

- Shelf Life

- 2 years

- Storage Conditions

- Ideal temperature conditions: 0 to 30°C.

- Exposure: avoid direct exposure to sunlight.

- With time, the color of the product may turn darker, but it doesn’t modify its properties.