Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Carrier

- INCI Name

- Ingredient Origin

- Cosmetic Ingredients Functions

- Technologies

- Product Families

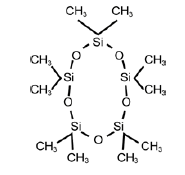

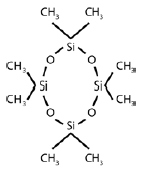

- Chemical Structure

Cyclopentasiloxane (D5)

Cyclotetrasiloxane (D4)

Features & Benefits

- Benefit Claims

- Labeling Claims

- Key Attributes

- Volatile carrier

- Compatible with a wide range of cosmetic ingredients

- Low surface tension

- Transient effect

- Excellent spreading

- Leaves no residue or build up

- Detackification

Applications & Uses

- Markets

- Applications

- Application Format

- AP/Deo Applications

- Bath & Shower Applications

- Color Cosmetic Applications

- Fragrances & Perfume Applications

- Hair Care Applications

- Nail Care Applications

- Skin Care Applications

- Sun Care Applications

- Recommended Applications

- A base fluid in a number of personal care products, with excellent spreading and lubrication properties and unique volatility characteristics.

- Antiperspirants, deodorants, hair sprays, cleansing creams, skin creams, lotions, bath oils, suntan and shaving products, make-up, nail polishes, perfumes and colognes.

- Can also be used as an additive to powder make-up, colognes and preshaves.

- In hair sprays; faster drying time in low VOC formulae.

- In cleansing products; XIAMETER™ PMX-0344 Cyclosiloxane Blend lifts and removes dirt without leaving any greasy residue.

- Usage

XIAMETER PMX-0344 Cyclosiloxane Blend is a volatile fluid with appreciable vapor pressure at ambient temperature.

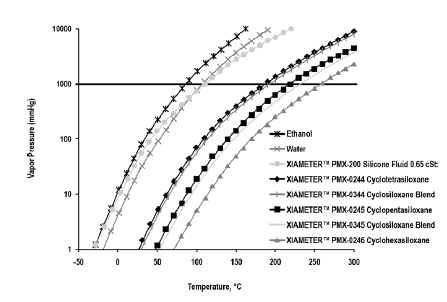

Figure gives typical vapor pressure vs temperature data for fluids along with those for water and ethanol. The data given should be helpful in determining volatility range and in calculating the partial pressure of the silicone in a formulated system.

Vapor pressure vs temperature of volatile Silicone fluids (and several common fluids).

Note that the tetramer component (D4) evaporates at a faster rate than the pentamer component (D5).

By using blends of cyclomethicones this difference in volatility can be used to vary the residence time of the silicone on the skin.

Unlike other volatile carriers used in the personal care industry, volatile silicone fluids do not cool the skin when they evaporate. This is a consequence of their unusually low heat of vaporization.Compatibilty

Fluid Water Incompatible Ethanol (200 proof) Compatible Glycerine Incompatible Octyl methoxy cinnamate Compatible Waxes Stearyl alcohol Compatible Beeswax Compatible Paraffin wax Compatible Myristyl myristate Compatible Stearic acid Compatible Hydrocarbons Mineral oil Compatible Petrolatum Compatible Isododecane Compatible Isopar H Compatible Polydecene Compatible Oils Almond oil Compatible Castor oil Incompatible Jojoba oil Compatible Soybean oil Compatible Sunflower oil Compatible Esters Isopropyl myristate Compatible Isopropyl palmitate Compatible Octyl palmitate Compatible C12-C15 Alcohol benzoate Compatible Capric/caprylic triglycerides Compatible Octyldodecanol Compatible Oleyl alcohol Compatible

Properties

- Physical Form

- Appearance

- Colorless liquid

- Typical Properties

Value Units Test Method / Conditions Water Content max. 150 ppm Corporate Test Method 0911 D4 (Chromatogram 0554) 68.00 - 100.00 % Corporate Test Method 0053 D5 (Chromatogram 0554) 5.00 - 32.00 % Corporate Test Method 0053 D4 + D5 (Chromatogram 0554) 90.00 - 100.00 % Corporate Test Method 0053 Acid Number max. 0.0100 mg KOH/g - Refractive Index (at 25°C) 1.3920 - 1.3970 - - Specific Gravity (at 25°C/15.6°C) 0.949 - 0.955 - - Color max. 35 - APHA Viscosity 2.20 - 3.00 cSt - Surface Tension (at 25°C) 19 Dynes/cm - Flash Point 52.0 °C Closed cup Freeze Point 15.0 °C - Boiling Point (at 760 mm Hg) 177 °C - Heat of Vaporization (at 25°C) 168 kJ/kg - Heat of Vaporization (at 25°C) 168.0 kJ/kg -

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Storage & Handling

- Shelf Life

- 900 Days

- Usable Life and Storage

- Product should be stored at 5°C (9°F) above its freezing point. If the material does freeze on no account should a naked flame be used to melt the product.

- Care should be taken when handling volatile fluids at temperatures 10°C below the quoted flash point.

- As with any flammable material, containers should be kept tightly closed and away from heat, sparks, open flames, and other sources of ignition.