Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- CASE Ingredients Features

Applications & Uses

- Markets

- Applications

- Applicable Processes

- Compatible Polymers & Resins

- Adhesive & Sealant Type

- Applications

Dixie dodecenylsuccinic anhydride (DDSA) is a slightly viscous liquid anhydride. DDSA can be used as

- An epoxy curing agent for electrical potting compounds, coatings, conductive adhesives, and syntactic foams

- An intermediate in the preparation of corrosion inhibitors for oils and greases

- As a leather tanning agent.

When used as an epoxy-curing agent, it has a long pot life at room temperature and gives excellent electrical properties and flexibility to castings. DDSA can be used in blends with other anhydrides to modify physical properties of the mixture and to lend flexibility and reduce brittleness of cured polymers.

- Modifying Other Anhydrides

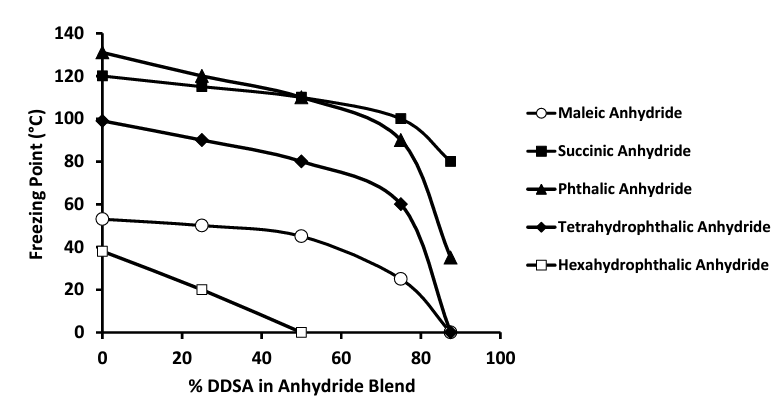

As a liquid, DDSA is useful in modifying other anhydrides to lower their freezing points and make them easier to handle. The following plot shows how DDSA lowers the freezing point of five other anhydrides.

- Anhydride Level

Most applications use between 80-150 phr DDSA with bisphenol A liquid epoxy resins. Most high performance applications where high levels of heat or chemical resistance, or high strength is required utilize about 140 phr.

Example

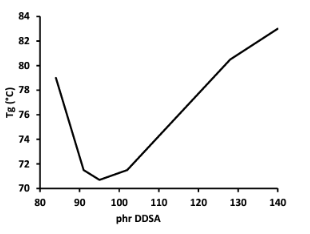

Formulations with 100 parts EPON Resin 828 (Momentive), DDSA, and 1.5 part BDMA were prepared. The level of DDSA was varied from 84-140 phr. Samples were cured for 30 minutes at 100°C, the temperature was increased to 160°C in ten minutes, and then post-cured for 30 minutes. The following plot summarizes the glass transition temperatures (Tg) for these formulations:

The same experiments were conducted with a 20:80 blend of DDSA and hexahydrophthalic anhydride. The following table summarizes the Tg data for these tests.

Anhydride blend (phr) Tg (°C) 84 79 90 71 95 71 100 71 110 77 125 71 135 85 145 81

Properties

- Physical Form

- Appearance

- Light Yellow Liquid

- Typical Properties

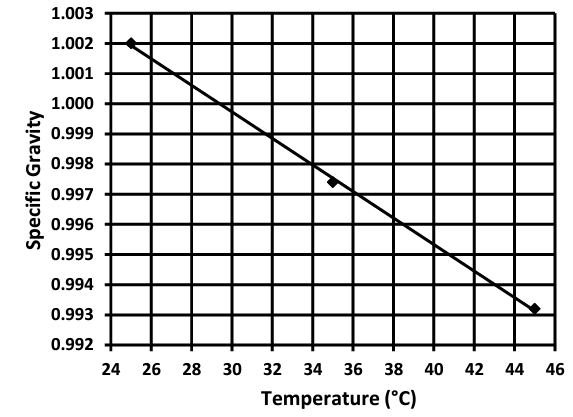

Value Units Test Method / Conditions Specific Gravity 1.002 g/cc D-102 (ASTM D 4052) Vapor Pressure max. 1 mm Hg - Boiling Point 173-190 ° C ASTM D86 Flash Point 157 ° C ASTM D93 Molecular Weight 266 - Electrical Properties

A formulation with 100 parts EPON Resin 828 (Momentive), 138 parts DDSA, and 1.46 part BDMA was prepared. Samples were cured for 4 hours at 80°C, and post-cured for 24hours at 100°C. The following table summarizes electrical, mechanical, and heat stability data for this formulation.

Dielectric Constant

at 60 Hz

at 1 MHz2.85

2.79Power Factor

at 60 Hz

at 1 MHz0.0039

0.0084HDT (°C) 77 Izod Impact (ft lb/in. notch) 0.22 Flexural Strength (ksi) 13.2 Flexural Modulus (ksi) 350 % Wt. loss 24 hr at 200°C 0.35

Technical Details & Test Data

- Specific Gravity as a Function of Temperature

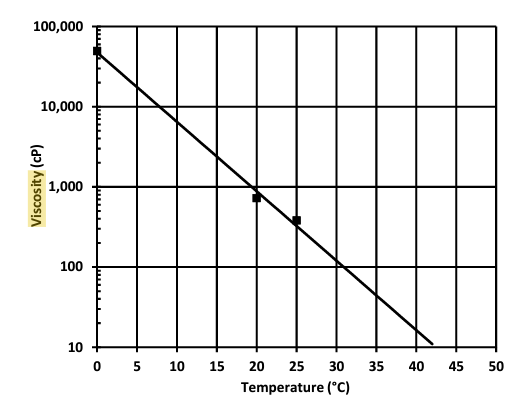

- Viscosity as a Function of Temperature

- Cure Catalysts

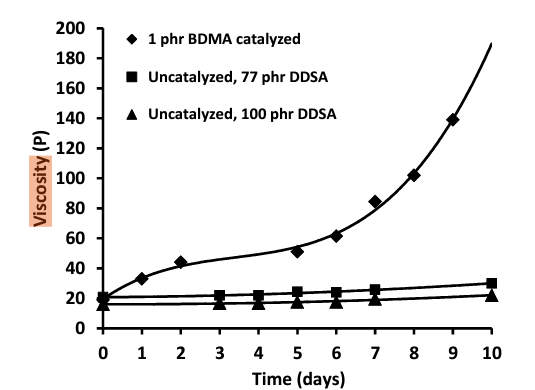

The effect of benzyldimethylamine (BDMA) catalyst on mix stability was studied using the following formulations:

System Catalyzed Uncatalyzed Uncatalyzed EPON Resin 828 (Momentive) 100 100 100 DDSA 133 77 100 Benzyldimethylamine (BDMA) 1 0 0 Epoxy homopolymerization discussed above is a significant side reaction for uncatalyzed systems, so anhydride demand is less.

Viscosity as a function of time is summarized in the following plot:

- Cure Cycle

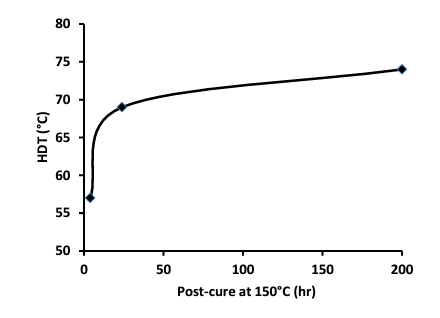

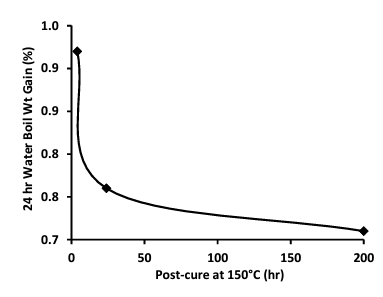

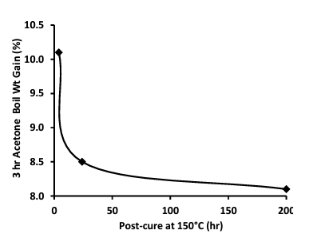

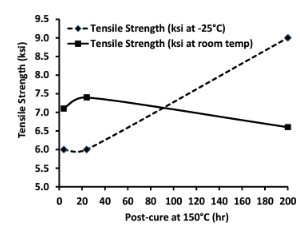

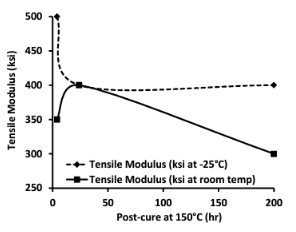

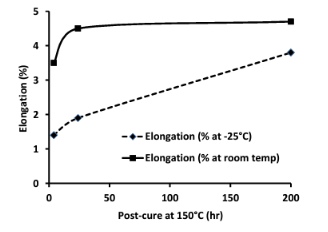

A formulation with 100 parts EPON Resin 828 (Momentive), 134 parts DDSA, and 1 part BDMA was prepared. Samples were cured for 4 hours at 90°C, and post-cured for 4, 24, and 200 hours at 150°C. The following plots show the effect of post-cure on heat distortion temperature (HDT), and weight increases after 24 hours in boiling water and 3 hours in boiling acetone.

Tensile testing was performed at -25°C, and at room temperature. The following plots summarize results for tensile strength, tensile modulus, and elongation at break.

Safety & Health

- Safety Precautions

Read and understand the relevant Material Safety Data Sheets (MSDS) for all products before use. These anhydrides are primary skin and eye irritants. Avoid contact with skin, eyes, and clothing. Use only with adequate ventilation. In case of contact, follow the procedures outlined in the MSDS. Generally, these procedures include immediately flushing the affected skin or eyes with copious amounts of water for at least 15 minutes. In the case of eye contact, get medical attention. Wash contaminated clothing before reuse.

Follow the recommendations in the MSDS for personal protective equipment when handling these materials. At a minimum, these procedures typically include protective chemical goggles, impenetrable gloves, and measures to avoid breathing chemical vapors.

Storage & Handling

- Storage

DDSA will react with water to form dodecenylsuccinic acid. This is normally undesirable, so DDSA should be stored in such a way that it is carefully protected from moisture contamination.