Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Food Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- Food Ingredients Features

- Product Highlights

Numerous efforts are being made to reduce the salt content of bakery products, but this often causes problems in the production process because low-sodium doughs have less fermentation stability. Saltase, an innovative enzyme system from DeutscheBack, solves this problem and ensures good dough stability and machinability. It enables bakeries to reduce the salt content of their range without loss of quality.

- Benefits of Saltase

- Salt reduction without adjustments to the process

- Dryer dough surfaces

- Better machinability

- Stronger dough structure

- Greater gas retention capacity

Applications & Uses

- Markets

- Applications

- Food & Nutrition Applications

- Salt - A Flavour Carrier With a Technical Function

Since salt is an important component of the recipe with the task of strengthening the gluten network, reduction of this ingredient may have a negative eff ect on fermentation tolerance and the texture and shred of the loaf. In other words, a low salt content does not only aff ect the taste: it also changes the rheology of the dough and the appearance and texture of the baked product. Our applications technologists at DeutscheBack have tackled this problem, and together with the enzyme specialists from their sister company SternEnzym they have developed a new functional system that prevents loss of quality in low-sodium bakery products.

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- High Fermentation Stability Even at 40 Percent Replacement

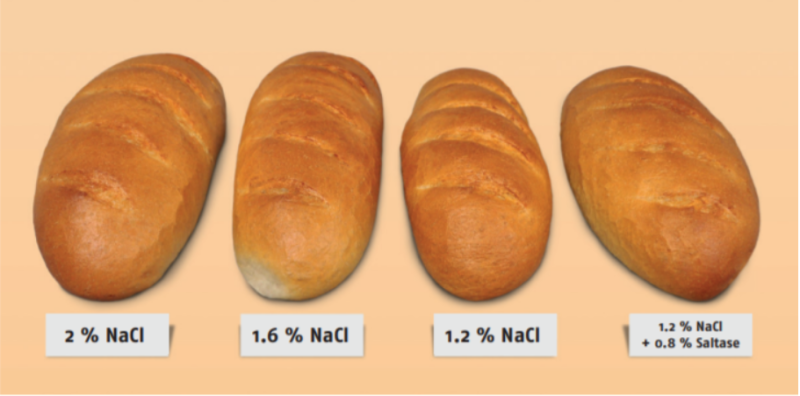

Baking trials at our Stern-Technology Center revealed that it was quite possible to reduce the amount of salt from 2 to 1.2 percent in wheat loaves. Since the activity of the yeast and also the oven rise and baked volume increase when the salt content is reduced, there is in principle a risk that the structure of low-sodium doughs will collapse towards the end of proofing. Fig. 1 shows that the dough already weakens during proofi ng when the salt content is reduced to 1.6 percent, and that at 1.2 percent salt the surface looks irregular. This is also refl ected in the baked loaves in Fig. 2: the volume is noticeably smaller. Fig. 3 shows that the volumes with 2 percent salt and 1.2 percent salt plus 0.6 percent Saltase are similar and the crumb structure is very uniform.

Fig. 1: White bread doughs with different salt levels and treatment with Saltase after proofing.

Fig. 2: White bread with different salt levels and treatment with Saltase after baking.

Fig. 3: White bread with different salt levels and treatment with Saltase; appearance when cut.