Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Pigment Type

- CASE Ingredients Functions

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Materials Features

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Applications

- NightGlo NG-200 exhibits excellent heat stability. It is recommended that it be used in plastic resins such as acrylics, nylons, polystyrene, polyolefins and vinyl. Recommended concentration is approximately 10% by weight.

- NightGlo NG-200 can be mixed with certain transparent pigments or colorants such as DayGlo fluorescent dyes and pigments. This combination will achieve some very attractive special effects. Recommended loading is a 1 to 10 ratio of fluorescent to phosphorescent pigment.

Properties

Regulatory & Compliance

Technical Details & Test Data

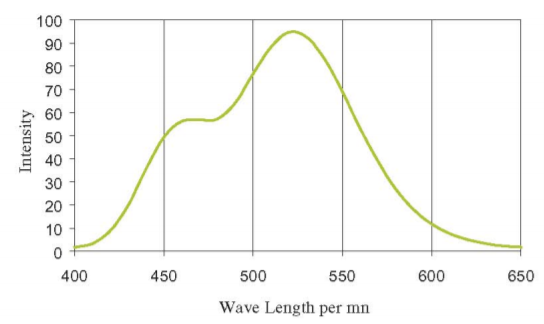

- Emission Spectrum

Storage & Handling

- Precautions

When handling phosphorescent pigment, some precautions should be taken when:

• Working with strong acids since this can cause dissolution of phosphorescent pigments.

• In the presence of high relative humidity and sunlight, phosphorescent pigments can exhibit darkening.

It is not recommended to mill this product since this will degrade the phosphorescence due to breakdown of the crystal structure of the phosphorescent pigment. Mild stirring should be used to incorporate NG-200 into a vehicle.

The addition of colorless extenders or colored pigments will reduce the intensity of the phosphorescence.

Testing is recommended in the intended application to determine suitability.