Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Dye Type

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Applications

- DAY-GLO Fluorescent Dyes should be applied in a concentration range of 0.05%-0.1%.

- To obtain maximum color development, the dye must be completely dissolved in the plastic resin.

- Recommended Applications

D-208 Apache Yellow Polyolefin NR Polystyrene E ABS E Polycarbonate E Acrylic E Nylon 6 G PET E PVC, Rigid* G E = Excellent G = Good - should be tested first NR = Not Recommended *Dyes may bleed in PVC.

Properties

- Color

- Physical Form

- Typical Properties

Value Units Test Method / Conditions Acetone 0.006 - - Bulk Density 23.1 ml/gram - Chemical Class Organic Dye - - Chemical Type Aminoketone - - Ethyl Acetate 0.006 - - Ethyl Alcohol max. 0.01 - - Hiding Power Transparent - - M.E.K. 0.01 - - Melting Point min. 325 ºC - MMA monomer 0.01 - - Specific Gravity 1.2 - - Sublimation 315 ºC - Xylene 0.02 - - - Heat Stability

Code Color % Dye GPPS D-838 Potomac Yellow 0.05 581

Regulatory & Compliance

Technical Details & Test Data

- Test Data

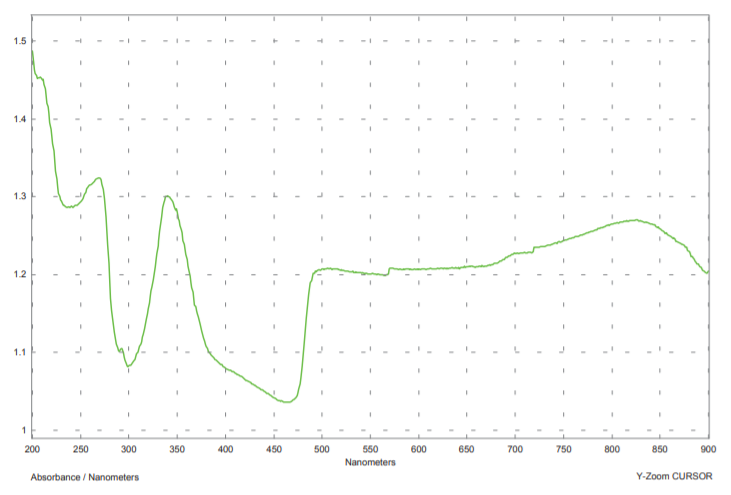

- Transparency

DAY-GLO dyes offer maximum transparency and, therefore, excellent edge glow in clear resins.

- Lightfastness

Code Color % Dye GPPS D-838 Potomac Yellow 0.05 500