Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Cleaning Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- HII Features

- Product Highlights

- Readily biodegradable

- Based on a natural primary alcohol

- Excellent wetting

- Low surface tension

- Good cleaning especially on greasy soils

- Performance Highlights

The NatSurf™ surfactants are DfE approved (NatSurf 205 pending) nonionic alcohol ethoxylate surfactants based off a natural primary alcohol. The NatSurf™ range has been developed as part of Croda’s commitment to offering high performance, environmentally friendly cleaning surfactants. The NatSurf™ series can be used as a nonyl phenol ethoxylate replacement.

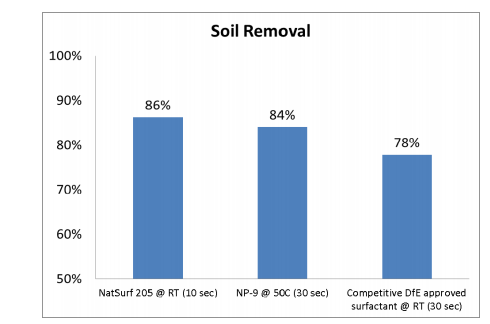

Figure 1: NatSurf™ 205 outperformed competitive products with regards to soil removal. Not only did NatSurf™ 205 achieve better cleaning with less dwell time (10 seconds compared to 30 seconds), it did so at room temperature, whereas NP-9 was tested at 50°C.

Applications & Uses

- Markets

- Applications

- Home Care Applications

- I&I Cleaning Applications

- Applications

- Hard surface cleaning

- Industrial & institutional cleaning

Properties

- Physical Form

- Appearance

- Clear liquid

- Soluble in

- Water

- Typical Properties

Value Units Test Method / Conditions Cloud Point (at 1%) 37 °C Wetting (1000 ppm) 8 sec. pH (at 1%) 4 - 5 Wetting (1500 ppm) 4 sec. Foaming (at 1000 ppm) 105 - 90 mm Surface Tension (at 1000ppm) 27 mN/m

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- NPE Replacement

HLB Comparison NP-6

NP-7

NP-810.9

11.7

12.311.5 NatSurf 205 - Cleaning Performance

Three cleaning studies were performed to show the performance of NATSURF surfactants against recognized leading commercially available green cleaning products.

Methodology

In all three studies, the Gardner Scrubber (Figure 1) was used to reproduce the action of household cleaning.

Soiled vinyl tiles were prepared by spreading 0.2g of a prepared soil (Table 1) across the surface of the tile, allowing the tile to dry at room temperature followed by placing the tile in a 100°C oven for 20 minutes to leave a baked on soil residue.

Figure 1. Gardner Scrubber used to reproduce the action of household cleaning

Figure 1. Gardner Scrubber used to reproduce the action of household cleaningTable 1. Composition of soil used in cleaning performance study

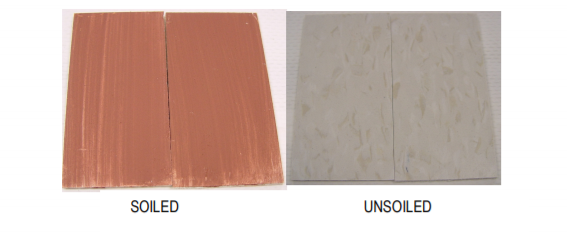

Ingredient Wt % Odorless Mineral Spirits 63.40 Carnation Mineral Oil 1.60 Crisco 1.60 Carbon Black 0.30 Metallic Brown Iron Oxide 15.50 Black Charm Clay 16.00 Motor oil (Used) 1.60 Total 100.00 The soiled tiles (Figure 2) were held in place on the base of the linear motion Gardner Scrubber (see Figure 1).

Figure 2. A soiled tile (left) after it was removed from the oven vs. an unsoiled tile (right)

Figure 2. A soiled tile (left) after it was removed from the oven vs. an unsoiled tile (right)Two separate sponges were then saturated in 230ml of a test solution and clamped in place. The remaining test solution was then poured over the soiled tiles and allowed to soak for 30 seconds. The clamped saturated sponges were then swept (back and forth) across each tile 5 times. Each tile was then removed from the base of the scrubber and rinsed under a light stream of cold water for 3 to 4 seconds.

Each tile was then examined using a color instrument to measure the % soil removal (%SR). The cleaning performance of each test solution can be measured from the following equation

%SR = (Lt-Ls / Lo-Ls) x 100

Lo is the L value for the original unsoiled white vinyl time

Ls is the L value for the soiled tile

Lt is the L value for the treated or cleaned tile