Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Technologies

- Product Families

Features & Benefits

- HII Features

- Product Highlights

- Upgrades the typically inadequate viscosity of low solids softener dispersions.

- Eliminates the need for DI water - saving money and deionizer capacity. · Dispersion viscosity is unaffected by moderate shear forces.

- Dispersion viscosity is stable to storage conditions in cold or hot warehouses.

- Very low use levels (0.075%-0.15% typical) for modest viscosity increases.

- Works over a broad quat solids range.

- Compatible and effective with all cationic fabric softener quats.

- Linear relationship between viscosity and addition rate-provides excellent viscosity control.

- Superior rheology - thickened dispersions are non-stringing and non-gelling.

- Opacifies the dispersion giving it a rich and creamy appearance.

- Can improve freeze/thaw stability of softener dispersions.

- No adverse impact on softener quat performance efficacy.

- Performance Highlights

INCROSOFT 8000 has been evaluated for its thickening capabilities in the three quat systems most often utilized in the formulation of low solids fabric softener dispersions. These three quat types represent the most effective chemistry for the formulation of these cost sensitive, low solids systems. The primary chemistry used, diamidoamine based quats, is represented by the Croda’s INCROSOFT T-90. The secondary chemistry, imidazoline based quats, is represented by the Croda’s INCROSOFT S-90. A less used chemistry in the US, ester quats, is represented by INCROSOFT TEA.

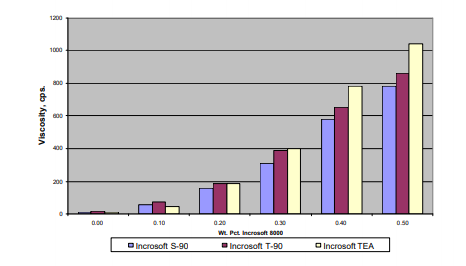

The following graph demonstrates the effect that the INCROSOFT 8000 use level and the quat type have on finished product viscosity. The viscosities were measured with a Brookfield Viscometer (Model RVT) at 20 rpm using #1 or #2 spindles depending on the viscosity. Note that viscosities increase even more as quat solids are raised.

Viscosity Effects of Incrosoft 8000 on 3% Fabric Softener

Applications & Uses

- Markets

- Applications

- Use Level

- 0.075 - 0.15%

- How It Works

INCROSOFT 8000 is an emulsion of cationic polymer particles. When added to quat dispersions, the polymer particles absorb water and swell to many times their original volume. The viscosity of the quat dispersion increases due to the presence of these large spherical polymer particles in the matrix. Since the quat and the additive are both cationic, compatibility is excellent. In fact, incorporation of INCROSOFT 8000 seems to improve dispersion stability.

- Formulation Conditions

- Hard water generally produces lower viscosity fabric softener dispersions. The same trend can be seen in dispersions which are thickened with INCROSOFT 8000. It is therefore recommended that the water used be as soft as is practical.

- In addition to thickening diamidoamine, imidazoline and ester type quats, INCROSOFT 8000 has been shown to be an effective thickener of other softener quat types like DHTDMAC.

- INCROSOFT 8000 is stable down to pH 2. Below this pH hydrolysis of the polymer can occur resulting in a loss of performance.

Properties

Technical Details & Test Data

- Overcomes Viscosity Control Problems

Traditional thickeners such as quar gums and cellulose ethers require critical minimum use levels before any thickening takes place. Once this point is reached, the viscosity response curve can rise too sharply. Viscosity drift over time also tends to be a problem. All this can make it difficult to get reproducible results. In contrast, the viscosity response to INCROSOFT 8000 additions is immediate and relatively linear. This rapid and predictable response makes it simple to achieve the desired dispersion viscosities batch after batch.

- Easy To Use

INCROSOFT 8000 can easily be poured or pumped from the drum. It is generally recommended that the INCROSOFT 8000 be predispersed in the charge water prior to addition of other ingredients. This provides for optimum swelling of the polymer particles. Once the INCROSOFT 8000 has been added, allow the mixture to stabilize with 20 minutes of mixing at low to moderate shear. After this, proceed with your standard formulation protocol but avoid application of excessive shear. The result will be a consistent and esthetically pleasing finished product.

Even higher viscosities are possible if the INCROSOFT 8000 is added to the softener dispersion after all other ingredients have been added and a homogeneous dispersion has been achieved. At this point, INCROSOFT 8000 should then be slowly added to the dispersion. Try to avoid adding too much at once. Continue high sheer agitation for another 45 minutes, after all INCROSOFT 8000 has been added. Avoid air entrainment. The resulting product will be consistent in viscosity and appearance.

Packaging & Availability

- Country Availability

- Regional Availability