Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Cleaning Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- HII Features

- Product Highlights

- Highly efficient gellants with high fragrance loading

- Wide fragrance compatibility

- Steady fragrance release and maintenance of fragrance integrity

- Water and temperature resistant

- Innovative design possibilities

- Structurant for liquid actives. Thermoset gel formed via curing with reactive isocyanates. Used in combination with CrystaSense IM700

CrystaSense IM700 is a novel oil and fragrance gellants designed to create eye-catching air freshener gels.

- Air Care with Appeal

- Steady Fragrance Release

- Flexible Formulation

Applications & Uses

- Markets

- Applications

- Home Care Applications

- Applications

- Space air fresheners for home, industrial and institutional applications

- Automotive - gels will not melt in hot vehicles

- Aqueous environments like dishwashers and toilets as gels are water-resistant

- Further potential applications i.e. insect repellents

Properties

- Physical Form

- Odor

- Mild

- Appearance

- Viscous Liquid

- Typical Properties

Value Units Test Method / Conditions Color Value (Gardner) 1 - - Density (25°C) min. 1.00 g/cm³ - Viscosity at 23°C 18 - - Flash Point 204 (399) °C (°F) - Vapor pressure at 20°C 0.0013 hPa -

Technical Details & Test Data

- Flexible Formulation

Cure time

CrystaSense IM700 polymerises significantly faster than CrystaSense IM800 under the same conditions to give the same end product; therefore they should be used together in varying ratios to control the desired cure time of formulations. Initially while a formulation is in development the recommended ratio of CrystaSense IM700 to CrystaSense IM800 is 1:3. Table 3 shows example cure times for a formulation containing 50% fragrance oil and different ratios of CrystaSense oil gellants.

% CrystaSense IM700 % CrystaSense IM800 Cure Time (min) 90 10 1 80 20 5 70 30 15 60 40 75 50 50 250 Table 3: Example cure times for a formulation containing 50% fragrance oil and different ratios of the CrystaSense IM Series. Results are fragrance dependant.

Fragrance Oil Cure Time (min) With CrystaSense IM700 With CrystaSense IM800 “Outdoor Breeze” ~ 15 s 400 “Tropical Splash” 34 420 “Clean Citrus” 39 ~ 20 hr “Cotton Fresh” 54 ~ 30 hr Table 4: Example cure times for a formulation containing 50% fragrance oil and 50% of either CrystaSense IM700 or CrystaSense IM800

Curing

The CrystaSense IM series require the addition of approximately 4% curing agent for the material to harden. Recommended curing agents are solvent-free isocyanurate trimers available from Bayer Corporation under the trade name DESMODUR; DESMODUR N 3300 is used in all Croda formulations.

Diluents

Diluents are primarily used to bulk formulations where low levels of fragrance are used, however they can also be used to reduce viscosity, reduce syneresis (when liquid exudes to the surface of an object), and to a limited extent adjust final object flexibility and fragrance release. Polyamide polyamines are compatible with a wide range of medium-polarity organic compounds but not well suited to very low and very high polarity liquids like hydrocarbons, linear silicone oils, diols and water. Dipropylene glycol is a compatible diluent, and both Crodamol AB and Span 80 show compatibility with the CrystaSense IM series. It is important that the diluent polarity should match the fragrance polarity.

Dyes and Fragrance

Many oil-soluble dyes can be used to color gels made with the CrystaSense IM series, however some dyes may lose stability in the presence of the other gel ingredients, and a slight color change may occur. Table 5 shows 12 dyes that were assessed for change in color when used in a CrystaSense IM gel; C12 -15 alkyl benzoate was used as a diluent.

Colorant Name Index Name Color Test Result Yellow 2GLN Yellow 88 Yellow-orangeish No color change Orange G Orange 11 Orange-brownish No color change Red G Red 125 Orange-red No color change Blue GN Blue 67 Bright blue Slight shade shift Red BL Red 122 Bright magenta pomegranate Slight shade shif D208 Apache Yellow Solvent Green 5 Fluorescent yellow No color change D098 Pocono Yellow Solvent Yellow 98 Fluorescent yellow No color change D314 Marigold Orange Solvent Orange 115 Fluorescent orange No color change Green G-A Pigment Green 7 Bright green No color change Solvent Green 3 Solvent Green 3 Greenish-blue No color change Sudan Blue II Solvent Blue 35 Blue No color change Sudan Red 7B Solvent Red 19 Bright magenta-pomegranate No color change Table 5: Color changes observed for formulations containing dye, C12-15 alkyl benzoate and a CrystaSense IM gellant

Fragrances of all polarities can be used with the CrystaSense IM gellants; however incompatibilities with other ingredients can cause syneresis. This can be solved by replacing or adding a more compatible diluent or adjusting the proportions of the liquids.

Formulating

Production of gels containing the CrystaSense IM series requires no heat. The CrystaSense IM gellants are quickly mixed together with the liquid active and dye until homogeneous, the curing compound is mixed in, and the mixture is poured into molds and allowed to set. Gels then can be removed from flexible molds without cracking or distortion. Although curing requires no heat, it can be used to accelerate the reaction of the polyamide polyamines with the curing agent.

Table 6 shows a typical immobilized fragrance oil formulation. The percentage of fragrance and diluent will depend on the end cost and application.

Component Percentage CrystaSense IM Serie 26% Diluent 0 – 60% Fragrance 10 – 70% Desmodur N3300 4% Table 6: Guide formulation for an air freshener gel

- Efficacy Studies

Air Care with Appeal

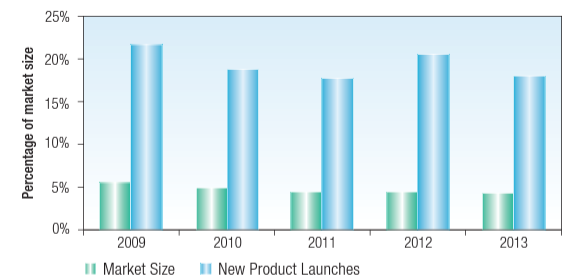

Air care is a highly innovative area within household cleaning which is shown in the consistently high level of product launches relative to the market size (Figure 1 ). Trends predict that consumers will continue to seek new concepts and a more sensory experience from their air care purchases.

Figure 1: Percentage of air care product launches within global household launches and percentage of overall household market size since 2009.

The CrystaSense series effectively gels high levels of fragrance oil and satisfies consumer needs with a product that is also visually striking. CrystaSense IM700 transform functional oils into transparent, solid gels with the option of embedding glitter or other articles for further sensory appeal.

Gels made with CrystaSense IM are water-resistant and heat-resistant to 250°C. The gels will not melt in hot vehicles or other areas of high temperature, and are also suitable for aqueous environments within the home and in industrial applications.

Steady Fragrance Release

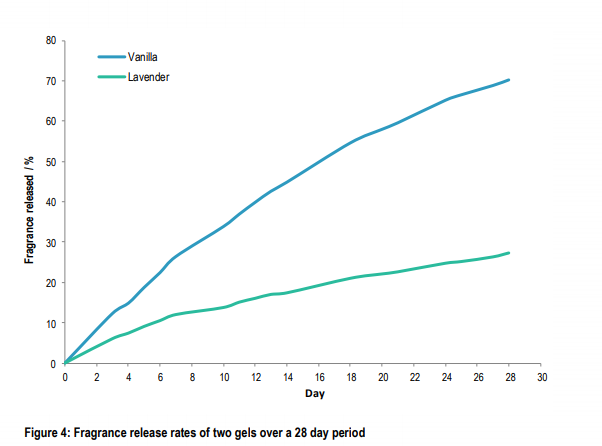

Figure 2: Fragrance release rates of formulations containing 35% fragrance, 35% Crodamol™ AB, 26% CrystaSense IM and 4% isocynaurate curing agent.

CrystaSense IM700 exhibit steady release of volatile components and are therefore an ideal solution for fragrance formulations. Gels formulated with the CrystaSense IM series provide long-lasting steady fragrance, ensuring that the product smells the same over its lifetime.

The fragrance release of two gels made with the CrystaSense IM series was measured over a 28-day period. The results of the testing show that the fragrance release of the two products is linear and predictable, but will vary depending on the fragrance used.

Packaging & Availability

- Country Availability

- Regional Availability