Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Name

- CASE Ingredients Functions

- CAS No.

- 1332-09-8

- EC No.

- 603-719-3

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

Applications & Uses

- Markets

- Applications

- Compatible Substrates & Surfaces

- Coating Type

- Interior Paints

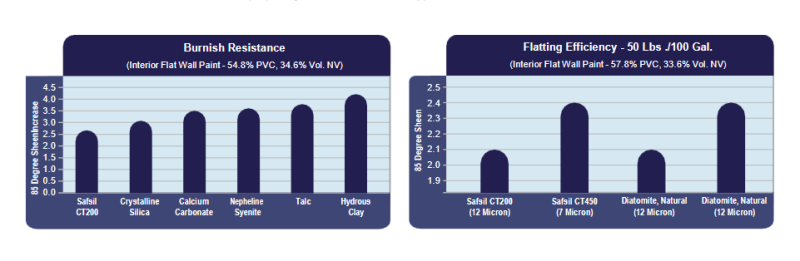

SafSil® pumice provides enhanced qualities in interior paints. By proper choice of pumice particle size, the following properties can be improved:

• Burnish resistance

• Flatting

• Abrasion resistance

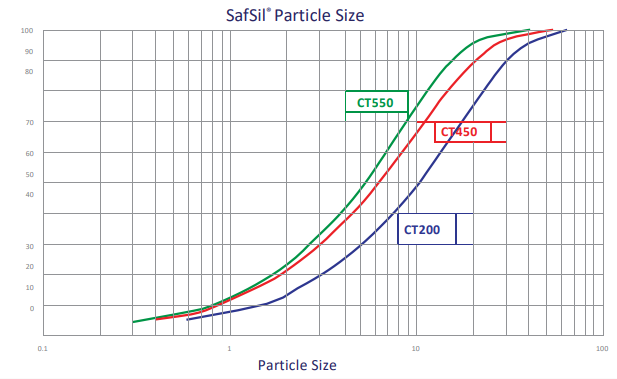

• Touch-upThe larger particle sizes of SafSil® CT200 and CT450 contribute most to improving these properties. SafSil® has also demonstrated excellent efficiency replacing natural diatomite in many paints.

The finer SafSil® CT450 and CT550 grades are a natural for use in paints with higher sheen/gloss requirements. Excellent satin and eggshell paints are being produced with these pumice materials.

- Exterior Paints and Stains

SafSil® is used to formulate exterior paints, primarily to improve the following properties:

- Tint retention

- Frost resistance

- Uses

- Floor Paints - The hardness, chemical resistance, and abrasive qualities of SafSil® pumice make it an ideal candidate for floor and deck coatings. SafSil® can also be used in driveway sealers. The material contributes to rheology and helps film reinforcement. Larger particle size Navajo Brand® pumice grades are used for non-skid floor coatings. Grades such as Grade ½ and Grade 3 have been used successfully.

- Primers and Undercoats - SafSil® is used for both architectural and industrial primers. The low soluble salt content of SafSil®, as measured by the ASTM D2448 Test Method, imparts improved corrosion properties to maintenance primers. Primers containing SafSil® demonstrate excellent “tooth” for subsequent topcoat adhesion. Even though SafSil® is a relatively hard material, with a Mohs hardness of 5.5-6.0, primers produced with SafSil® exhibit very good sanding qualities.

- Powder Coatings - SafSill® pumice is used successfully in powder coatings. The finer CT 450 and CT 550 grades are beneficial for systems with higher gloss and angular sheen, and the coarser CT200 and CT 450 grades work well for gloss control. SafSill® possesses greater Mohs Hardness than the more commonly used fillers in powder coatings. Dosages less than ten percent have increased film hardness and scratch resistance. Although SafSill® is relatively hard, it does not present any equipment wear issues. The exterior performance of SafSill® is well proven. Color and gloss retention are positive attributes of the material.

- Tennis Court Coatings - SafSil® is used successfully in tennis court systems. The material provides film reinforcement, sheen control and outstanding tint retention.

- Traffic Paint - SafSil® is efficacious for traffic paints. The hardness and abrasion resistance of the material makes it ideal for replacing some of the calcium carbonate in most systems. SafSil® can replace diatomite used by some formulators for flatting. Improved performance will occur due the obtaining increased “free binder”.

Properties

- Typical Properties

Value Units Test Method / Conditions Median Particle Size 7 Micron - Hardness 5.5 - 6.0 Mohs Scale - Bulk Density 48 Lbs./Cu. Ft. - pH Value (10% in Water) 9 - - Specific Gravity 2.34 - - Hegman Grind 4.5 - - Oil Absorption 27 - ASTM D281 GE Brightness 79 - - Wt./Gal 19.5 - - Refractive Index 1.5 - - Moisture Content max. 1 % - Silicon Dioxide (SiO2) 73 wt. % - Aluminum Oxide (Al2O3) 12 wt. % - Potassium Oxide (K20) max. 4 wt. % - Sodium Oxide (Na2O) max. 4 wt. % - Calcium Oxide (CaO) max. 2 wt. % - Magnesium Oxide (MgO) max. 2 wt. % - Titanium Dioxide (TiO2) max. 2 wt. % - Ferrous Oxide (Fe2O3) max. 2 wt. % -

Technical Details & Test Data

- SafSil® Particle Size