Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Polymer Name

- Reinforcement Material

- Composite Materials Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Key Features & Benefits

- Flexible cure temperature 65-120 °C

- Service temperature up to 120 °C

- Suitable for vacuum bag/oven, autoclave and press molding

- 21 days out-life at room temperature

- 12 months storage life at -18 °C

- Good tack and drape

- Toughened

- Excellent surface finish

- Available on a range of reinforcement fabrics

Applications & Uses

- Markets

- Applications

- Cure Method

- Composites End Use

- Composites Processing Methods

Properties

- Composite Properties

Mechanical Properties of Monolithic Laminates

Carbon

Typical data for laminates made from Evopreg® EPC300 205g/m2 2x2 twill high strength carbon fiber prepreg (Evopreg® EPC300-C205T-HS-3K-42-1250) cured in an autoclave for 1 hour at 120°C and 6 bar pressure.

Property Result Test method Fiber content by volume, Vf 47% - Density 1.48 g/cm3 - Cured ply thickness 0.24 mm/ply - Flexural strength, 0° 827 MPa ISO 14125 Flexural modulus, 0° 48.2 GPa ISO 14125 Tensile strength, 0° 617 MPa ISO 527-4 Tensile modulus, 0° 59.2 GPa ISO 527-4 Compressive strength, 0° 631 MPa ISO 14126 Compressive modulus, 0° 49.2 GPa ISO 14126 Apparent interlaminar shearstrength (ILSS), 0° 70.8 MPa ISO 14130 In-plane shear strength 109 MPa ISO 14129 Typical data for laminates made from Evopreg® EPC300 650g/m2 2x2 twill high strength carbon fiber prepreg (Evopreg® EPC300-C650T-HS-12K-38-1250) cured in an autoclave for 1 hour at 120°C and 6 bar pressure.

Property Result Test method Fiber content by volume, Vf 51% - Density 1.49 g/cm3 - Cured ply thickness 0.69 mm/ply - Flexural strength, 0° 737 MPa ISO 14125 Flexural modulus, 0° 46.0 GPa ISO 14125 Tensile strength, 0° 709 MPa ISO 527-4 Tensile modulus, 0° 55.0 GPa ISO 527-4 Compressive strength, 0° 451 MPa ASTM D6641 Apparent interlaminar shearstrength (ILSS), 0° 57.3 MPa ISO 14130 In-plane shear strength 144 MPa ISO 14129 1 Note

1. No clear failure, value taken at 5% strain

Technical Details & Test Data

- Processing and Curing

The prepregs can be processed using standard techniques including vacuum bag/oven,autoclave and press molding. Suggested cure cycles are shown below.

Cure temperature Minimum cure time Glass transition temperature Tg, onset E’ Glass transition temperature Tg, peak tan δ 80°C 12 hours 88°C 107°C 120°C 1 hour 123°C 142°C - Recommended ramp rate 1-3°C/min

- Cure times may need to be extended to account for thermal lag in large tools

- Optional post-cure 130°C for 1 hour - Tg onset E’ 124°C, Tg peak tan δ 145°C

- Tg data for laminates made from a woven carbon-reinforced epoxy prepreg (EvopregEPC300-C205T-HS-3K-42)

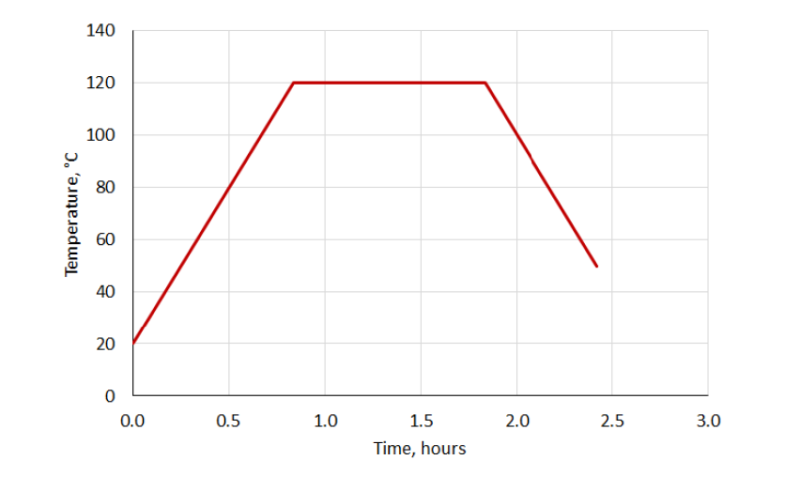

Suggested cure cycle for standard autoclave cures at 120°C:

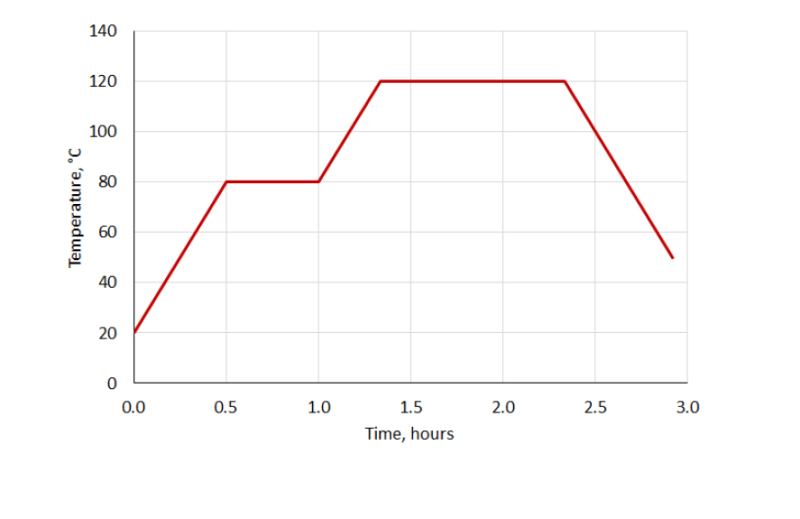

Alternative cure cycle to optimize surface finish for vacuum bag/oven cures at 120°C:

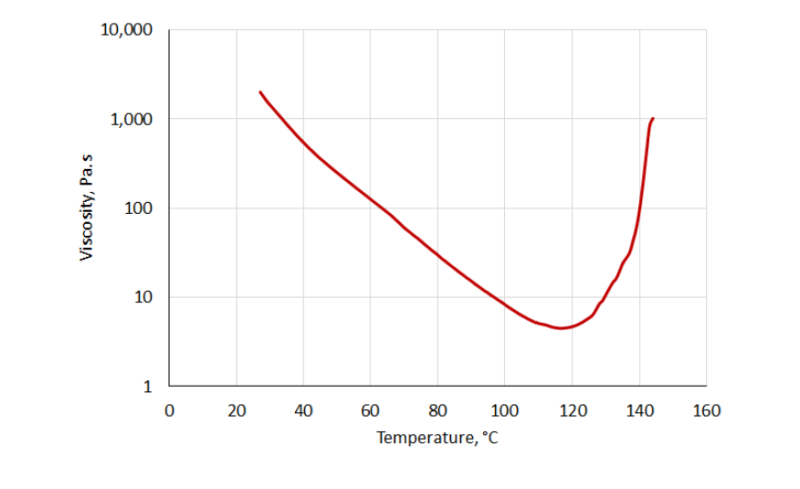

Viscosity Profile

Plate-on-plate, ambient temperature 25°C, shear rate 20s-1, ramp rate 2°C/min:

- Products Available

Evopreg prepregs are available with a wide range of reinforcements, including woven, non-woven, non-crimp stitched and unidirectional fabrics in the following fibers:

- Carbon

- Glass

- ampliTex™ Flax

- Aramid

- Hybrids

Safety & Health

- Health & Safety

Please refer to the Safety Data Sheet (SDS) before use. This material contains epoxy resin and fibers which can cause irritation to skin and eyes and allergic reactions. Wear appropriate PPE including overalls and impervious gloves, and ensure adequate ventilation. Exothermic reactions can occur when curing epoxy resins, and particular care must be taken when curing thick laminates.

Packaging & Availability

- Packaging Type

- Packaging

The material is typically delivered in rolls and with a silicone coated release paper on the bottom and a polythene release film on the top. Typical packaging - 76mm (3”) diameter cardboard core, polythene bag, reusable cable ties, cardboard box and end supports. Where relevant, multiple boxes are typically stacked on a standard wooden pallet, strapped and covered with stretch wrap. Other packaging may be available on request. We recommend retaining the boxed packaging to protect the material during storage.

Storage & Handling

- Shelf Life

- 12 Months

- Storage

The material should ideally be stored in a freezer at -18°C and sealed in a polythene bag. To protect the material, we recommend storing it in its original box with the end supports. To avoid moisture condensation, allow the material to defrost fully and reach room temperature before opening the polythene bag. Typical thaw time for full roll is 4-6 hours. Keep the material sealed in the polythene bag when not in use to prevent moisture absorption. The cable tie that seals the polythene bag is reusable. Out-life at room temperature is 30 days. Storage life at -18°C is 12 months.