Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Base Oil Type

- Metalworking Fluid Type

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Features and Benefits

- Well suited for applications where foam and ferrous corrosion control are critical in individual machines or central systems

- Very resistant to attack by mold and bacteria

- Extremely low foaming even under high agitation conditions

- Excellent settling properties allowing the mix to remain clean

- Exceptional tramp oil rejection. Oil floats on top of the mix and is easily removed by an oil skimmer

- Excellent ferrous corrosion control with rust inhibitors preventing corrosion of cast iron and steel

Applications & Uses

- Markets

- Applications

- Application Area

- Compatible Substrates & Surfaces

- Refractometer Calibration And Instruction For Use

1. Ensure that the refractometer (figure 1), water and metalworking fluid are at room temperature.

2. Place a few drops of water between the plastic cover and the prism.

3. Hold the refractometer horizontally and point it at a light source.

4. Look into the eyepiece and adjust the scale-calibrating screw until the boundary line, which separates the light and dark areas of the scale are aligned to zero “0” on the scale.

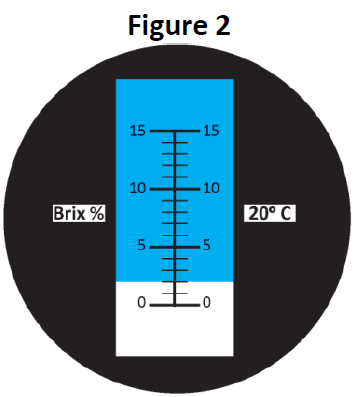

5. Lift the plastic cover and dry the prism with a clean, dry cloth.

6. Place one or two drops of the metalworking fluid on the prism and close the plastic cover.

7. Read the number on the scale at the point where the boundary line separates the light and dark areas on the scale (Figure 2). For the concentration, multiply this number by the refractometer factor.

CIMTECH® C205 to be mixed with water for use (add concentrate to water). Add no other substances to the concentrate or mix unless approved by CIMCOOL® Technical Services.

For concentration analysis, use Total Alkalinity Titration Procedure, BCG Titration Procedure, CIMCHEKTM Test Strip, or Refractometer.

Example:

CIMTECH® C205 Refactometer Factor = 2.5 Take the Refractometer Scale Reading of 2.0 (i.e. Figure 2), multiplied by the Refractometer Factor of 2.5 = 5.0% mix concentration.

Properties

- Color

- Physical Form

- Appearance

- Clear

- Odor

- Chemical

- Solubility in Water

- 100% Miscible

- Typical Properties

Value Units Test Method / Conditions Specific Gravity (H2O = 1) 1.04 - - Freezing Point (or Pour Point, °F, °C) -5.0 °C - pH, concentrate 9.4 - - pH Mix 5% (Typical Operating Conditions) 9.1 - - Silicones None - -

Technical Details & Test Data

- Recommended Starting Dilutions

For Industrial Use Only

Recommended Starting Dilution 5.0% (1:20) Typical Operating Range 5.0% (1:20) to 10% (1:10) Refractometer Factor 2.5 The table below demonstrates potential Refractometer readings and the concentration % derived by using the

following formula: (Refractometer Reading x Refractometer Factor = Concentration %)Refractometer Reading 1.2 1.6 2 2.4 2.8 3.2 3.6 4 Concentration % 3 4 5 6 7 8 9 10

Packaging & Availability

- Packaging

20 liter pails, 200 liter drums, and bulk containers