Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- CASE Ingredients Functions

- Technologies

- Product Families

- Chemical Structure

Aqueous emulsion of a polysiloxane

Features & Benefits

- Labeling Claims

- CASE Ingredients Features

- Product Features

- Highly effective

- Easy to incorporate in aqueous systems

- Improves slip significantly

- Improves scratch resistance

- improves abrasion resistance

- Improves block resistance

- Improves metal marking resistance

- Improves haptic properties

- Good water resistance

- VOC-free acc. to EU 2004/42/EG

- Cyclic siloxanes D4, D5, D6 as SVHCs <0.1%

Applications & Uses

- Markets

- Applications

- Coating Type

- Use Level

- 0.1 - 2%

- Fields of Application

Due to its chemical structure SILCO GA 5053 is particularly recommended for water based formulations. SILCO GA 5053 is particularly recommended as slip additive for use in printing inks and clear formulations such as overprint varnishes.

Preferred fields of application:

- Printing inks and overprint varnishes

- Water based systems

- Recommendation for Use

- We generally recommend a dosage of 0.1 - 2.0 % calculated on the total formulation.

- The optimal dosage has to be determined through preliminary tests.

- We recommend to add the additive at the end of the production process at low to medium shear forces.

Properties

- Physical Form

- Appearance

- Opaque to white liquid

- Typical Properties

Value Units Test Method / Conditions Non-Volatile Matter 63 - 67 % - - Stabilities

SILCO GA 5053 is sensitive to frost; after the impact of temperatures considerably below the freezing point irreversible changes could occur. The product is sensitive to temperatures above 40°C.

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Technical Details & Test Data

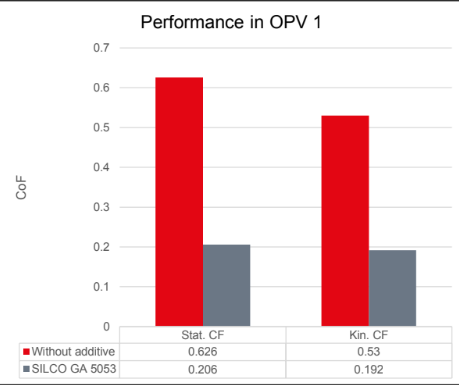

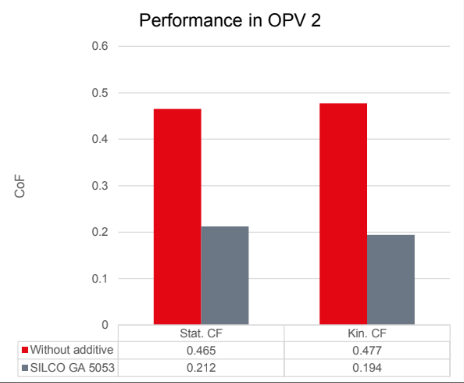

- Performance in OPV

SILCO GA 5053 has been tested in 2 different OPVs

- OPV 1 - Based on Joncryl resins (BASF)

- OPV 2 - Based on Induprint resins (Indulor)

Dosage & Application conditions

- Dosage of SILCO GA 5053 (65% active): 0.3%

- 6 μm wet layer with wire rod on magenta pre-printed Cards. Drying for 24h at RT

Performance criteria

Slip

- Slip and Friction Tester, supplier TMI - Testing Machines Inc., based on ASTM D 1894 / ISO 8295

- Static and kinetic CoF - Coefficient-of-Friction (Speed: 30 cm/min / 200g weight)

SILCO GA 5053 provides high slip by reducing the Coefficient of Friction (Static & Kinetic)

Storage & Handling

- Shelf Life

- 18 Months

- Storage Information

The product is stable for at least 18 months at well-ventilated areas. Avoid temperatures below 4°C and above 40°C. Prevent from freezing. Stir before use.