Enhanced TDS

Knowde-enriched technical product data sheet

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Key Features

- Convenient mixing 1:1 ratio for use in automatic dispensing equipment or hand mixing

- Contains no solvents

- Non-yellowing catalyst system

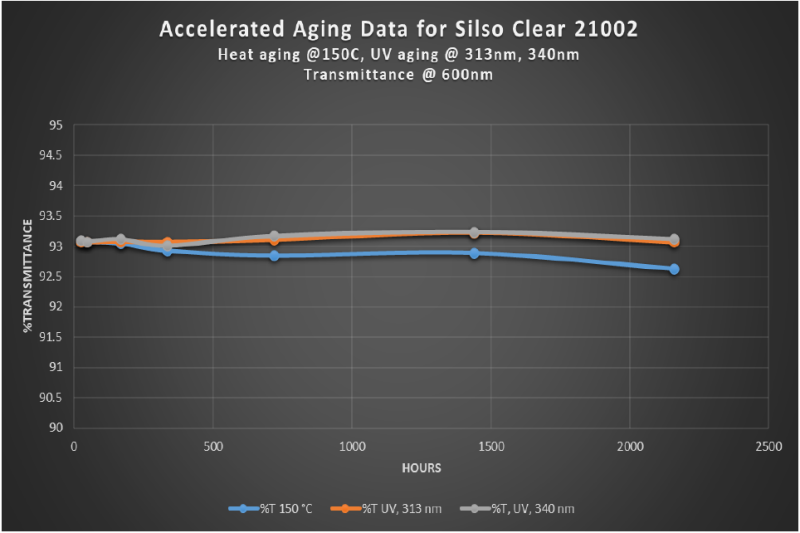

- Stable transmittance over time

Applications & Uses

- Markets

- Applications

- Application Area

- Cure Method

- Application

SilSo Clear 21002 is designed for optical injection molding applications such as lenses, lightguides and LEDs.

Key Applications

- Injection molding

- Optical / magnifying lenses

- LED modules

- Solar collection products

Use and Cure Information

Important

- In order to achieve optimum performance, the same lot number of the A and B components should be used. Mixed lots may not obtain the performance criteria listed on the TDS or Certificate of Analysis.

- The 'A' part of the product contains the platinum catalyst; great care should be taken when using automatic dispensing equipment. Please ensure that it is not contaminated by residual hydride containing rubber (Part B) in the dispensing equipment, as curing will result. If in doubt, it is advised to thoroughly purge the equipment with a suitable hydrocarbon solvent or silicone fluid.

Mixing

- Both the ‘A’ and ‘B’ parts should be well stirred to ensure the material is uniform. If utilizing machine-dispense, ensure the mixing device has sufficient elements to fully homogenize the components of the formulation.

- Place the required amount of ‘A’ and ‘B’ parts by weight at the mix ratio shown opposite, in a clean plastic or metal container of approximately 3 times their volume, and mix until the color of the mixture is uniform. For best results, we recommend vacuum degassing. Degas by intermittent evacuation, the larger volume of the mixing vessel helps prevent overflow during this operation. In the case of automatic dispensing with static mixing head, the two components should be degassed before processing. Recommended vacuum conditions are 30-50 mbar intermittently over 5-10 minutes.

Inhibition of Cure

Great care must be taken when handling and mixing all addition cured silicone elastomer systems, ensuring that all the mixing tools (vessels and spatulas) are clean and constructed in materials which do not interfere with the curing mechanism. The cure of the silicone can be inhibited by the presence of compounds of nitrogen, sulfur, phosphorus and arsenic; organotin catalysts and PVC stabilizers; epoxy resin catalysts and even contact with materials containing certain of these substances e.g. molding clays, sulfur vulcanized rubbers, condensationcure silicone rubbers, onion and garlic.

Curing Conditions

- The data offers a guide to the rate of cure at various temperatures, mixing of the components at temperatures between 15 and 25 °C is recommended to ensure adequate pot life for degassing and handling. The pot life can be extended to several hours by chiling the components before mixing.

- It is important to check the compatibility in preliminary tests if unknown substrates are used.

- Some formulations are not designed to cure at room temperature and may not develop full physical properties if cured below the minimum listed temperature. The recommended cure temperatures and times are provided for guidance only.

- The end user must test in their application and process as the quantity of material, size of part, and method of applying heat will influence time and temperature requirements.

Cure Time, injection molded at 150 °C 3 x 12 x 125 mm < 60 seconds

Properties

- Physical Form

- Electrical Properties

Value Units Test Method / Conditions Dielectric Breakdown max. 0.1 kV/mm - Dielectric Strength 18.7 kV/mm ASTM D-149 Volume Resistivity 1.0 x 10¹⁵ Ω.cm ASTM D-257 - Cured Properties

Value Units Test Method / Conditions CTE (Volumetric) 960.0 ppm/°C - Density 1.03 g/cm³ BS ISO 2781 Elongation (at Break) 110.0 % ISO 37 Hardness Shore A 67.0 - ASTM D 2240- 95 Linear Coefficient of Thermal Expansion 320.0 ppm/°C - Working Temperature Range -55 - 204 °C - Refractive Index 1.41 - - Tensile Strength 9.31 N/mm² ISO 37 Thermal Conductivity 0.18 W/mK - - Uncured Properties

Value Units Test Method / Conditions Density (Component A) 1.03 - BS ISO 2781 Density (Component B) 1.03 - BS ISO 2781 Pot Life (at 23°C) min. 24 Hours - Viscosity (Component A) 17000.0 cP Brookfield Viscosity (Component B) 10000.0 cP Brookfield Viscosity (Mixed) 13500.0 cP Brookfield - Uncured Product Property

Color A Clear Color B Clear Cure Type Addition Mix Ratio By Weight 1:1 Self Bonding No

Technical Details & Test Data

- Accelerated Aging Data for SilSo Clear 21002

Typical Optical Properties Refractive Index, 589 nm 1.41 Transmittance, 760 nm 93.1 Transmittance, 600 nm 93.0 Transmittance, 450 nm 92.8 Transmittance, 380 nm 92.3

Packaging & Availability

- Packaging

CHT silicone elastomers are available in a variety packaging including bulk containers.

Storage & Handling

- Shelf Life

- 24 Months

- Storage Conditions

Maximum storage temperature is 38 °C / 100 °F.